Best Printing Methods for Custom T-Shirts A Complete Guide

Creating custom t-shirts has never been more accessible, yet choosing the right printing method can feel overwhelming. Whether you’re launching a clothing brand, personalizing gifts, or starting a print-on-demand business, understanding the various t-shirt printing techniques is essential for achieving the quality and durability your designs deserve. This comprehensive guide explores the most popular printing methods, helping you make informed decisions for your custom apparel projects.

Understanding Custom T-Shirt Printing

Custom t-shirt printing has evolved significantly over the past few decades. What once required expensive equipment and large minimum orders is now accessible to everyone from hobbyists to professional manufacturers. The key to success lies in matching the right printing technique to your specific needs, considering factors like design complexity, fabric type, order volume, and budget constraints.

The t-shirt printing industry offers various methods, each with unique advantages and limitations. From traditional screen printing to modern digital techniques, understanding these options ensures you select the best approach for your project.

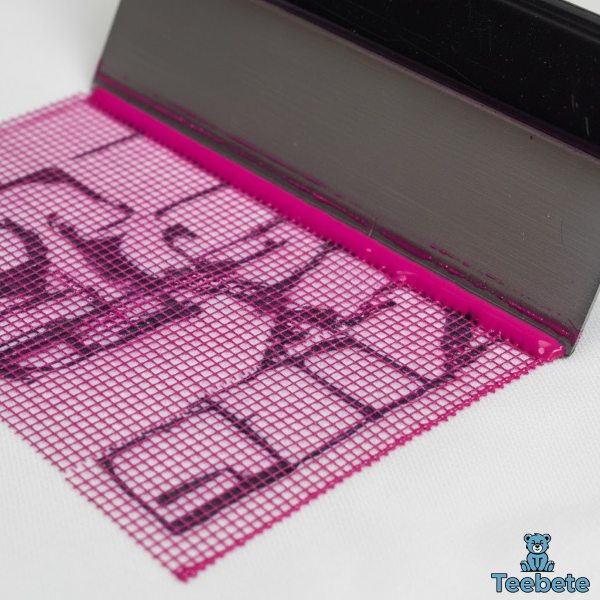

Screen Printing: The Time-Tested Classic

Screen printing remains one of the most popular t-shirt printing methods, particularly for bulk orders. This traditional technique has been used for decades and continues to dominate the industry for good reason.

How Screen Printing Works

Screen printing involves creating a mesh screen where a fine mesh is prepared with blocked-out areas, leaving open spaces where the design will appear. Ink is then pressed through the mesh with a squeegee or blade, transferring the design onto the t-shirt fabric. Each color in the design requires its own screen, making the process more time-intensive for multi-color designs.

The process begins with creating artwork and separating colors. Next, a film positive transparency is printed, which serves as a stencil. The screen is coated with a light-sensitive emulsion, and when exposed to light with the film positive in place, the emulsion hardens except where the design appears. After washing out the unhardened emulsion, the screen is ready for printing.

Advantages of Screen Printing

Screen printing offers several compelling benefits that make it ideal for many applications:

- Exceptional durability: Screen-printed designs withstand repeated washing without fading, cracking, or peeling

- Vivid colors: The thick ink layers produce bold, vibrant colors that stand out

- Cost-effective for bulk orders: Once screens are prepared, printing additional shirts becomes very economical

- Works on various fabrics: Screen printing excels on cotton and cotton blends, which absorb the inks well

Screen printing is ideal for designs with up to 5 colors and remains a popular choice for team shirts, corporate branding tees, and event merchandise because of the low per-unit cost when ordering in bulk.

Limitations to Consider

Despite its advantages, screen printing has some constraints. The setup process requires creating screens for each color, making it less economical for small orders. Additionally, screen printing is not ideal for intricate designs with fine details or photographic images. The method works best with solid colors and relatively simple graphics.

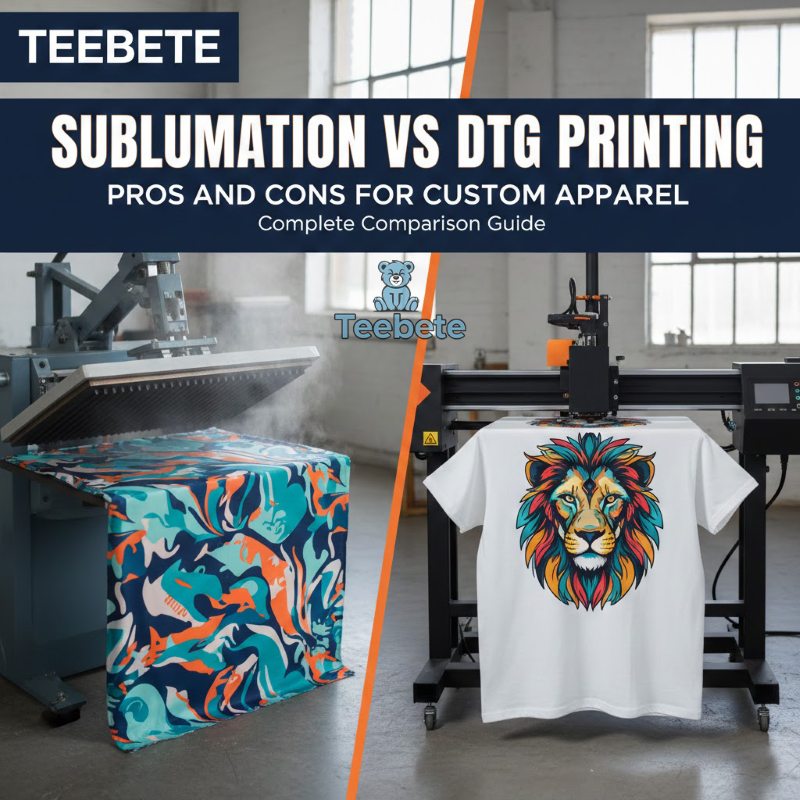

Direct-to-Garment (DTG) Printing: Digital Precision

Direct-to-garment printing represents the digital revolution in custom t-shirt printing. This method uses specialized printers that spray water-based inks directly onto t-shirt fabric, much like a standard inkjet printer applies ink to paper.

The DTG Printing Process

DTG printing uses a four-step process: First, a digital art file is created using graphic design software. The garment is then pre-treated with a special solution to help the ink adhere properly, ensuring vibrant colors and excellent washability. The shirt is loaded onto the DTG printer’s platen, and the printer sprays water-based inks directly onto the fabric. Finally, the ink is cured using a heat press or conveyor dryer to ensure permanence.

For dark garments, a white ink underbase is printed first to enhance the vibrancy of the colored inks. The printer then recreates intricate, full-color designs with CMYK inks, achieving photographic quality results.

Benefits of DTG Printing

DTG printing offers unique advantages that make it perfect for certain applications:

- Unlimited color options: DTG can reproduce virtually any color combination without additional setup costs

- Photorealistic quality: The technology captures fine details and gradients that other methods cannot match

- No minimum order requirements: Perfect for single-shirt orders or testing new designs

- Eco-friendly approach: Water-based inks are non-toxic and produce minimal waste

- Soft hand feel: The ink integrates with the fabric fibers, creating a print you can barely feel

DTG printing works best on cotton and cotton-blend fabrics, producing exceptional results on natural fibers. The method is widely regarded as environmentally sustainable, as the water-based inks are free of toxic chemicals and the process requires no additional materials like screens or paper.

DTG Limitations

The primary drawback of DTG printing is equipment cost. Professional DTG printers often cost tens of thousands of dollars, making them a significant investment. However, print-on-demand services like TEEBETE have made this technology accessible without requiring equipment ownership. DTG printing also works best on lighter-colored shirts or requires additional pretreatment for dark fabrics.

Heat Transfer Vinyl (HTV): Versatile and Accessible

Heat transfer vinyl provides an accessible entry point for custom t-shirt printing, particularly popular among crafters and small businesses. This method involves cutting designs from colored vinyl sheets and using a heat press to bond them to fabric.

Understanding HTV

Heat transfer vinyl comes in numerous colors and finishes, including matte, glossy, metallic, glitter, and specialty effects. The process involves creating or selecting a design, cutting it from vinyl using a vinyl cutter or cutting machine, weeding away excess vinyl, and then applying the design to the garment using a heat press.

Printable HTV allows you to print complex, multi-colored designs directly onto vinyl sheets using an inkjet printer, combining the versatility of digital printing with the durability of heat transfer vinyl.

HTV Advantages

- Wide variety of finishes: Access to specialty effects like glitter, foil, and holographic finishes

- Minimal equipment needed: Requires only a vinyl cutter and heat press (or even a household iron for small projects)

- Precise cutting: Automated vinyl cutters produce crisp, clean designs

- Layering capability: Multiple vinyl colors can be layered to create complex designs

HTV Considerations

While HTV offers versatility, it requires time for weeding (removing excess vinyl), especially with intricate designs. The durability, while good, may not match screen printing or DTG for long-term wear. Vinyl can eventually crack or peel with repeated washing, particularly if not applied correctly.

Sublimation Printing: Vibrant All-Over Designs

Sublimation printing stands out for its ability to create vibrant, all-over designs that become part of the fabric itself. This heat transfer method turns solid sublimation ink into gas under high temperatures, permanently bonding with polyester fibers.

The Sublimation Process

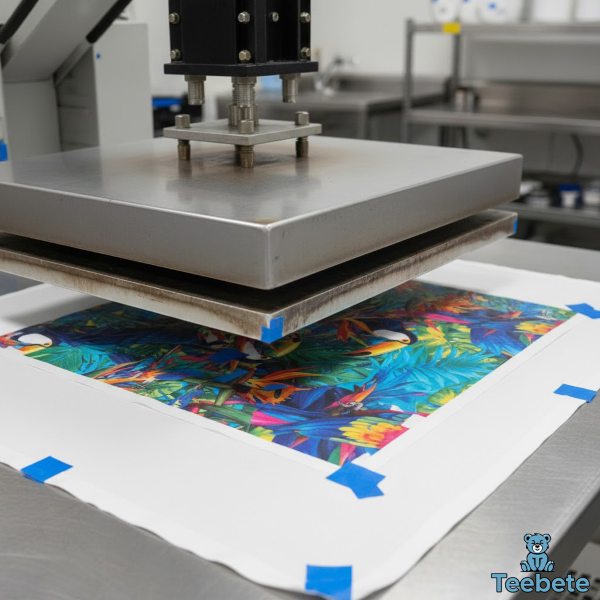

The sublimation process involves several key steps: First, a design is created using graphic design software. The design is printed onto special sublimation transfer paper using sublimation inks. The printed paper is placed face-down on the garment and secured with heat-resistant tape. A heat press applies high temperature and pressure, turning the solid ink into gas. The gas penetrates the polyester fibers, and when cooled, returns to solid form permanently bonded within the fabric.

Sublimation Advantages

- Unmatched vibrancy: Sublimation produces the most vivid colors of any printing method

- All-over printing capability: Designs can cover the entire garment from seam to seam

- Permanent bonding: The design becomes part of the fabric, never fading or peeling

- Soft, breathable results: No added layer on the fabric means the shirt maintains its natural feel

- Photographic quality: Capable of reproducing gradients and detailed photographs

Sublimation Limitations

The major limitation of sublimation printing is its material requirement. Sublimation only works on white or light-colored polyester fabrics, requiring at least 65% polyester content for optimal results. This makes it unsuitable for cotton garments unless they’re treated with a special polyester coating. Additionally, dark-colored shirts require workarounds involving white vinyl bases or specialty transfer papers.

Direct-to-Film (DTF) Printing: The Versatile Newcomer

Direct-to-film printing has emerged as one of the most versatile printing methods in recent years. DTF printing involves printing designs onto special film that is then transferred onto fabric using heat and pressure.

DTF Printing Process

The DTF process works by printing CMYK colors followed by white ink onto coated PET film. While the ink is still wet, hot-melt adhesive powder is applied to the printed areas. The powder is then cured using heat to activate the adhesive. Finally, the transfer is heat-pressed onto the garment and the carrier film is peeled away, leaving a vibrant, durable design.

DTF Benefits

- Exceptional fabric versatility: Works on cotton, polyester, nylon, blends, leather, and even non-textile materials

- No pretreatment required: Unlike DTG printing, fabrics don’t need pre-treating

- Vibrant colors on dark fabrics: The white ink base ensures colors pop on any garment color

- Cost-effective for small runs: More affordable than screen printing for limited quantities

- Intricate detail capability: Produces photorealistic quality similar to DTG

DTF Drawbacks

DTF printing requires specialized equipment including DTF printers, powder shakers, and curing ovens. The adhesive powder can be messy and requires careful handling. The process also needs proper ventilation due to fumes produced during curing, though modern eco-friendly inks have reduced this concern.

Comparison of Printing Methods

Understanding how these printing techniques compare helps you select the optimal method for your needs.

Best for Bulk Orders

Screen printing dominates bulk production due to its economy of scale. Once screens are created, each additional shirt costs very little to produce. For orders of 50+ shirts with simple designs, screen printing offers unbeatable per-unit pricing.

Best for Complex Designs

DTG and DTF printing excel at reproducing complex, multi-color designs with photographic detail. Both methods handle gradients, shading, and intricate patterns that would be cost-prohibitive with screen printing.

Best for Small Batches

DTG, DTF, and HTV all work well for small batch orders or single items. These methods have minimal setup costs, making them economical even for one-off projects. Print-on-demand services leverage these technologies to make custom apparel accessible to everyone.

Best for Durability

Screen printing produces the most durable prints, with properly cured inks lasting the lifetime of the garment. Sublimation also offers exceptional durability since the design becomes part of the fabric itself. DTG and DTF prints are durable but may show some fading after extensive washing and wear.

Best for Fabric Versatility

DTF printing wins for fabric versatility, working on virtually any material including cotton, polyester, blends, and specialty fabrics. Screen printing works well on most natural and synthetic fabrics. Sublimation is limited to polyester, while DTG performs best on cotton and cotton blends.

Choosing the Right Method for Your Project

Selecting the best t-shirt printing method depends on several key factors:

Design Complexity

Consider your design’s color count and detail level. Simple logos with one to three solid colors work perfectly with screen printing or HTV. Complex, photographic designs require DTG, DTF, or sublimation printing.

Order Volume

For large quantities (100+ units), screen printing offers the best value. For small batches or single items, DTG, DTF, or HTV provide economical alternatives. Medium-sized orders (20-100 units) may benefit from DTF or screen printing, depending on design complexity.

Fabric Type

Cotton and cotton blends work best with screen printing, DTG, or DTF. Polyester fabrics are ideal for sublimation or DTF. For mixed fabric types within a single order, DTF offers the most flexibility.

Budget Considerations

Initial investment varies dramatically. Screen printing requires significant upfront costs for screens and setup but offers low per-unit costs for bulk orders. DTG and DTF require expensive equipment unless using print-on-demand services. HTV offers the lowest equipment entry cost but higher per-unit expenses.

Turnaround Time

DTG and DTF printing provide the fastest turnaround for small orders since there’s no screen preparation. Screen printing requires setup time but can produce large quantities quickly once prepared. Sublimation and HTV fall somewhere in between.

Quality Considerations and Best Practices

Achieving professional results requires attention to several quality factors regardless of which printing method you choose.

Design File Preparation

Always use high-resolution images of at least 300 DPI for best results. Vector graphics work best for screen printing and vinyl cutting, while raster images at high resolution suit DTG, DTF, and sublimation. Ensure your design files use appropriate color modes: CMYK for printing and RGB for digital design work.

Fabric Selection

Choose fabrics appropriate for your printing method. Pre-wash garments before printing to remove sizing and prevent shrinkage after printing. Consider fabric weight, texture, and composition when planning your designs.

Print Durability

Follow proper curing procedures for each printing method. Screen prints need adequate curing time at correct temperatures. DTG and DTF prints require proper heat pressing. Provide care instructions to customers, recommending inside-out washing in cold water and avoiding bleach.

Color Accuracy

Understand that colors may appear different on screen versus printed. Request sample prints before large production runs. Consider how fabric color affects final appearance, especially with DTG printing on colored shirts.

Environmental Considerations

Sustainability has become increasingly important in the custom apparel industry. Different printing methods have varying environmental impacts.

Eco-Friendly Options

DTG printing uses water-based inks that are non-toxic and biodegradable, making it one of the most environmentally friendly options. Modern sublimation inks are increasingly eco-conscious with low VOC formulations. Screen printing can be eco-friendly when using water-based inks instead of plastisol.

Waste Reduction

Print-on-demand models eliminate overproduction and excess inventory waste. DTG and DTF printing produce minimal material waste compared to screen printing, which generates waste from screen preparation and cleaning. Digital printing methods allow precise inventory management, reducing unwanted stock.

Cost Analysis

Understanding the true cost of each printing method helps with budgeting and pricing decisions.

Setup Costs

Screen printing has high setup costs but low per-unit costs for large runs. DTG and DTF have minimal setup costs, making them ideal for testing new designs. HTV equipment is affordable, but material costs add up quickly for large orders.

Per-Unit Costs

Screen printing becomes more economical as order volume increases. DTG and DTF maintain consistent per-unit pricing regardless of quantity. Sublimation offers competitive per-unit costs for polyester products.

Hidden Costs

Consider labor time for weeding HTV or preparing screens. Factor in equipment maintenance and supplies like emulsion, films, and cleaning solutions. Account for reject rates and quality control when calculating true costs.

Starting Your Custom T-Shirt Business

If you’re considering launching a custom t-shirt business, understanding these printing methods positions you for success.

Equipment Investment

Start small with print-on-demand services to test market demand before investing in equipment. If purchasing equipment, HTV setups offer the lowest entry point, while screen printing and DTG require substantial investment. Consider used or refurbished equipment to reduce initial costs.

Choosing Your Niche

Identify your target market and their needs. Small businesses and sports teams often prefer screen printing for bulk orders. Individual consumers and online retailers benefit from DTG or DTF’s flexibility. Event coordinators value quick turnaround times that digital printing provides.

Partnering with Print Providers

Print-on-demand services like TEEBETE eliminate equipment costs and inventory management. These partnerships allow you to focus on design and marketing while experts handle production. Look for providers offering the printing methods that match your design style and target market.

Frequently Asked Questions

Which t-shirt printing method is best?

The best method depends on your specific needs. Screen printing works best for bulk orders with simple designs. DTG excels at complex, colorful designs in small quantities. Sublimation is ideal for all-over polyester prints. DTF offers the most versatility across different fabrics. Consider your order volume, design complexity, fabric type, and budget when choosing.

What is the best option for t-shirt printing?

For most beginners and small businesses, DTG or DTF printing through print-on-demand services offers the best balance of quality, flexibility, and accessibility. These methods require no equipment investment and handle both simple and complex designs effectively. As your business grows and you identify consistent high-volume needs, screen printing may become more economical.

Which is better, DTG or DTF?

DTG produces slightly softer prints and works best on cotton and cotton blends, offering exceptional detail and color reproduction. DTF works on more fabric types including cotton, polyester, nylon, and blends, making it more versatile. DTF doesn’t require fabric pretreatment, simplifying the process. DTG typically provides better color vibrancy on light-colored cotton shirts. Choose DTG for premium cotton apparel and DTF for versatility across fabric types.

Is DTF or screen printing better?

Screen printing delivers more durable prints and costs less per unit for large orders of 50+ shirts. DTF provides faster turnaround, works on more fabric types, and handles complex designs more economically for small to medium batches. Screen printing requires significant setup time and costs, making it impractical for small orders. DTF offers more flexibility for on-demand printing and design variations. Choose screen printing for large, consistent orders and DTF for smaller batches or diverse designs.

How long do different printing methods last?

Screen printing typically lasts the lifetime of the garment when properly cured and cared for. Sublimation prints are permanent since the dye becomes part of the fabric. DTG and DTF prints last 50+ washes with proper care, though some fading may occur over time. HTV durability varies by quality and application but generally lasts 50+ washes before showing wear. Proper care, including washing inside-out in cold water and avoiding bleach, extends the life of all prints.

Can I use a regular printer for custom t-shirts?

No, regular printers cannot be used for most professional t-shirt printing methods. DTG requires specialized textile printers designed for fabric printing. Sublimation needs printers converted to use sublimation inks. DTF requires dedicated DTF printers. Only printable HTV and some transfer papers work with regular inkjet printers, though results may not match professional equipment. For business-quality results, invest in appropriate equipment or use professional printing services.

What’s the most cost-effective printing method for small businesses?

For small businesses just starting out, print-on-demand services using DTG or DTF offer the most cost-effective solution since they eliminate equipment costs, inventory, and minimum order requirements. As you scale and identify consistent product demand, investing in screen printing equipment becomes cost-effective for bulk production. HTV provides a middle ground with affordable equipment but higher per-unit material costs.

How do I prepare designs for printing?

Create designs at 300 DPI minimum resolution for best print quality. Use vector formats (AI, EPS, SVG) for screen printing and vinyl cutting. Save in PNG or TIFF with transparent backgrounds for DTG and DTF. Convert to CMYK color mode for accurate color reproduction. Ensure designs fit within printable areas and account for seams and garment construction. Always request sample prints before large production runs.

Summary of Key Points

| Printing Method | Best For | Fabric Types | Durability | Setup Cost | Per-Unit Cost |

|---|---|---|---|---|---|

| Screen Printing | Bulk orders (50+), simple designs | Cotton, cotton blends | Excellent | High | Low (volume) |

| DTG Printing | Complex designs, small batches | Cotton, cotton blends | Good | High equipment / Low POD | Moderate |

| Heat Transfer Vinyl | Custom one-offs, specialty finishes | Most fabrics | Good | Low | Moderate to High |

| Sublimation | All-over prints, vibrant colors | Polyester only | Excellent | Moderate | Moderate |

| DTF Printing | Versatile fabric needs, detailed designs | All fabric types | Good to Excellent | High equipment / Low POD | Moderate |

Conclusion

Choosing the best printing method for custom t-shirts requires understanding your specific needs, from design complexity and order volume to fabric type and budget constraints. Screen printing remains the gold standard for bulk production and durability. DTG and DTF printing offer unmatched flexibility and detail for smaller orders. Sublimation creates the most vibrant all-over designs on polyester. Heat transfer vinyl provides accessible entry to custom apparel creation.

The custom t-shirt printing industry continues evolving with improving technologies and more accessible equipment. Whether you’re creating shirts for personal use, starting a business, or expanding an existing brand, understanding these printing methods empowers you to make informed decisions that balance quality, cost, and efficiency. Consider starting with print-on-demand services to test different methods before investing in equipment, and don’t hesitate to combine multiple techniques as your needs grow and diversify.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.