DTG Printing Explained How It Works & Why It’s Popular for T-Shirts

What is Direct-to-Garment (DTG) Printing?

Direct-to-garment printing, commonly abbreviated as DTG printing, represents a revolutionary digital printing technology that allows detailed and full-color designs to be printed directly onto fabric using specialized inkjet technology. Unlike traditional screen printing methods that require separate stencils for each color, DTG printing applies water-based ink directly onto garments, creating high-resolution, vibrant prints with exceptional detail and color accuracy.

The global DTG printing market was valued at approximately $1.92 billion in 2024 and is projected to reach $3.90 billion by 2030, growing at a remarkable compound annual growth rate (CAGR) of 13% from 2025 to 2030. This explosive growth reflects the increasing consumer demand for personalized apparel, custom merchandise, and print-on-demand services across the fashion and promotional products industries.

This modern printing method has become especially popular for custom t-shirt printing due to its ability to capture intricate designs, produce unlimited color variations, and maintain a soft, natural feel on fabric. Whether you’re a small business owner, an independent fashion designer, or an established brand, DTG printing offers a convenient and high-quality solution for custom apparel decoration without the constraints of minimum order quantities.

The Complete DTG Printing Process: Step-by-Step

1. Design Preparation and File Optimization

The DTG printing process begins with proper digital file preparation. Your artwork must be uploaded to the printer’s digital interface and carefully adjusted for optimal size, color accuracy, and resolution. High-quality digital files—preferably in formats like PNG with transparent backgrounds or high-resolution JPEG—produce sharper, more professional final prints. Most DTG printers work best with files at 300 DPI (dots per inch) resolution to ensure maximum detail reproduction.

The design preparation stage also involves color profiling to ensure what you see on screen matches the printed output. Professional DTG operators use RIP (Raster Image Processing) software to convert digital artwork into printer-ready files while managing color profiles, ink density, and print resolution settings.

2. Fabric Pre-Treatment Application

Before printing begins, the garment undergoes a crucial pretreatment process, especially for darker-colored fabrics. A specialized pretreatment solution—typically a water-based polymeric emulsion—is applied to the printing area. This solution fills the spaces between fabric fibers, creating a smooth, receptive surface for ink adhesion.

The pretreatment serves multiple essential functions. It prevents ink from soaking into the fabric fibers, ensures better color vibrancy and opacity (particularly important for white ink on dark garments), enhances wash durability and colorfastness, and creates a chemical reaction that causes white ink to semi-cure instantly upon contact, producing a smooth printable surface for colored inks.

Pretreatment can be applied manually using spray bottles or foam rollers, or automatically using dedicated pretreatment machines. According to industry experts, proper pretreatment application is the most critical factor affecting final print quality, second only to garment selection itself.

After application, the pretreatment must be dried—either through air drying or using a heat press—before printing can begin. Proper drying removes excess moisture and ensures optimal ink-to-fabric bonding during the printing stage.

3. Digital Printing with Precision Inkjet Technology

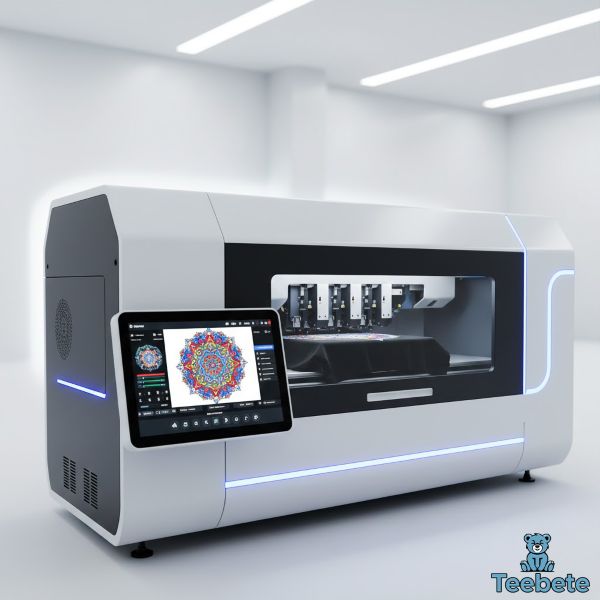

Once the garment is pretreated and dried, it’s loaded onto the DTG printer’s platen—a flat surface that holds the fabric taut and properly positioned. Modern DTG printers use advanced inkjet print heads that spray microscopic droplets of water-based ink directly onto the fabric surface with extreme precision.

The printer applies ink in multiple passes, layering colors simultaneously to create smooth gradients, photorealistic details, and unlimited color combinations. Most DTG printers utilize CMYK (Cyan, Magenta, Yellow, Key/Black) ink formulations, often with additional white ink channels for printing on dark garments. This allows for millions of color variations without additional setup costs per color—a significant advantage over traditional screen printing.

The printing speed varies depending on design complexity, garment size, and printer model, but a typical t-shirt can be printed in 2-5 minutes. Industrial DTG systems can output 200-400 pieces per hour, making them suitable for both small custom orders and medium-scale production runs.

4. Heat Curing and Final Quality Control

After printing, the garment proceeds to the curing stage, where heat is applied to permanently set the ink into the fabric. This crucial step is typically performed using either a heat press (for smaller operations) or a conveyor dryer (for higher-volume production facilities).

The curing process usually requires temperatures between 320-356°F (160-180°C) for 25-45 seconds, depending on the ink type and fabric composition. Proper curing ensures the design becomes permanent, resistant to fading, and able to withstand multiple wash cycles. According to garment printing specialists, well-cured DTG prints can maintain their quality through 50+ wash cycles when cared for properly.

Following heat curing, quality control inspections verify print accuracy, color consistency, and overall finish quality before the garment is packaged and prepared for delivery.

Why DTG Printing Has Become the Industry Standard for Custom Apparel

Exceptional Print Quality and Detail Reproduction

DTG printing technology enables truly high-resolution images with photographic-quality detail, making it ideal for designs featuring fine lines, intricate patterns, shading effects, and complex photographic elements. Unlike screen printing, where complex images can be challenging and costly to reproduce, DTG ensures crisp, lifelike prints with smooth color gradients and precise detail rendering down to the pixel level.

The digital nature of DTG printing means there’s virtually no design complexity limitation—whether you’re printing detailed illustrations, typography with small font sizes, or full-color photographs, the technology maintains exceptional clarity and color accuracy throughout.

Unlimited Color Options Without Additional Costs

One of the most significant advantages of DTG printing is its ability to reproduce unlimited colors in a single print without incurring additional setup fees. DTG printers use CMYK ink combinations that can produce millions of color variations, making them perfect for intricate designs that require extensive color palettes, photorealistic images, gradient effects, and multi-colored artwork.

This stands in stark contrast to traditional screen printing, where each additional color requires creating a separate screen, significantly increasing both setup time and production costs. With DTG printing, a two-color design costs the same to produce as a twenty-color design, providing unprecedented creative freedom for designers and cost predictability for businesses.

Superior Fabric Feel and Comfort

Since DTG inks are water-based and absorbed directly into the fabric rather than sitting on top of it (like vinyl heat transfers or plastisol screen prints), DTG prints maintain an exceptionally soft texture that doesn’t compromise the garment’s breathability or comfort. The printed area remains flexible and moves naturally with the fabric, ensuring comfortable wear without the heavy, stiff, or plasticky feel associated with some traditional printing methods.

This soft-hand feel is particularly important for fashion brands and premium apparel lines where garment comfort and wearability are paramount to customer satisfaction and brand reputation.

Environmentally Sustainable Printing Solution

Water-based DTG inks are non-toxic, biodegradable, and environmentally friendly compared to traditional printing methods. According to sustainability experts, DTG printing minimizes environmental impact in several ways: it uses only the necessary amount of ink for each print, reducing chemical waste; produces minimal water waste compared to screen printing cleanup processes; eliminates the need for film separations and screen disposal; and typically uses eco-friendly, water-based ink formulations without harmful PVC-based components.

For brands prioritizing sustainability and eco-conscious consumers, DTG printing offers a more responsible production method that aligns with environmental values without compromising print quality.

Perfect for Small-Batch Production and Customization

DTG printing requires virtually no setup costs—unlike screen printing, which demands screen creation for each design and color. This makes DTG ideal for small-batch orders, single-item customization, test designs before committing to large production runs, print-on-demand business models, and personalized merchandise with variable data (names, numbers, etc.).

Businesses can offer truly on-demand printing services without maintaining large inventories, significantly reducing waste, storage costs, and capital tied up in unsold stock. This flexibility has revolutionized the custom apparel industry, enabling entrepreneurs and small businesses to compete effectively without substantial upfront investment.

Rapid Turnaround Times

With digital file processing and direct ink application, DTG printing is significantly faster than traditional methods for small to medium-sized orders. A single shirt can be completed in minutes from start to finish, making DTG an efficient solution for online stores requiring quick fulfillment, event merchandise with tight deadlines, last-minute custom orders, and sample production for design approval.

The combination of minimal setup time and quick printing speed allows businesses to operate with shorter lead times, respond rapidly to market trends, and provide superior customer service through faster delivery.

When DTG Printing is Your Best Choice

While DTG offers incredible benefits for many applications, understanding when it performs optimally helps you make informed production decisions:

Short-Run and Small-Batch Printing: DTG excels for orders ranging from single units to several hundred pieces, where the lack of setup costs makes it more economical than screen printing.

Complex and Detailed Designs: Best suited for intricate graphics, photorealistic images, multi-color artwork with gradients, and designs requiring fine detail reproduction that would be difficult or impossible to screen print effectively.

Custom and Personalized Products: Perfect for print-on-demand businesses, personalized t-shirts with names or custom text, unique one-off creations, and variable data printing where each item differs.

Natural Fabric Compositions: DTG technology works best on 100% cotton or high-cotton blend fabrics (50% cotton or higher), as natural fibers absorb water-based inks most effectively. While specialty pretreatments enable printing on polyester and poly-cotton blends, pure cotton garments consistently deliver optimal results.

Quality-Focused Brands: When brand image depends on premium product quality, soft hand feel, and exceptional detail, DTG printing delivers results that meet or exceed customer expectations for high-end custom apparel.

DTG Printing vs. Alternative Printing Methods: Comprehensive Comparison

Understanding how DTG compares to other printing technologies helps you select the optimal method for your specific needs:

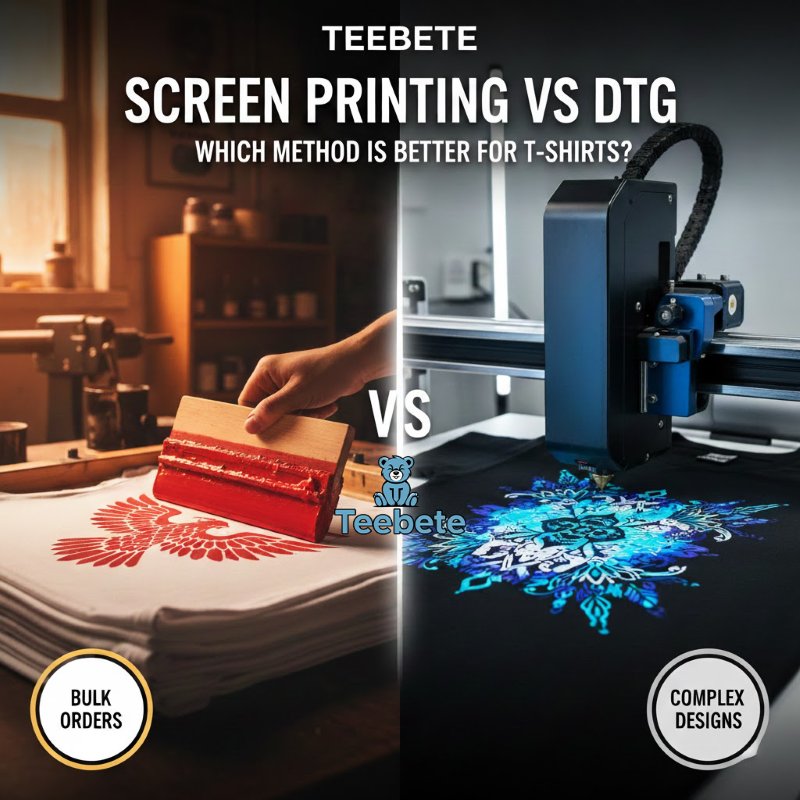

DTG vs. Screen Printing

Industry comparisons reveal distinct advantages for each method depending on production requirements:

Best Use Cases: DTG excels for small orders (1-100 units) with detailed, multi-color designs, while screen printing is ideal for large bulk orders (100+ units) with simple, bold designs and limited colors.

Color Capabilities: DTG offers unlimited full-color printing with no additional costs per color, whereas screen printing requires separate screens for each color, making complex designs expensive.

Print Feel: DTG produces soft prints where ink absorbs into fabric, while screen printing creates thicker ink layers that sit on top of fabric, resulting in a more pronounced texture.

Setup Costs: DTG has minimal to no setup costs, making single-item orders economically viable. Screen printing involves significant setup costs (screen creation, color registration), requiring larger order quantities to achieve cost-effectiveness.

Durability: Screen printing with plastisol inks typically offers superior wash durability (lasting the garment’s lifetime with proper care). DTG prints maintain quality through 50+ washes when properly cured and cared for, though colors may gradually fade over extensive use.

Environmental Impact: DTG is more eco-friendly, using water-based inks and minimal waste. Screen printing uses more chemicals, requires water-intensive cleanup, and generates more production waste.

Production Speed: For bulk orders, screen printing is faster once setup is complete. For small orders, DTG offers quicker turnaround with immediate printing capability.

DTG vs. Heat Transfer Printing

Heat transfer (including vinyl cutting and sublimation transfers) represents another popular decoration method with distinct characteristics:

Application Method: DTG prints directly onto fabric, while heat transfers apply pre-printed designs using heat and pressure.

Fabric Feel: DTG maintains soft, breathable prints. Heat transfers can feel plasticky or stiff, particularly vinyl transfers, and may crack or peel over time.

Design Complexity: DTG handles intricate, photorealistic designs effortlessly. Heat transfers work best for simple graphics and solid colors, with limitations on gradients and fine details.

Durability: DTG offers moderate durability with proper care. Heat transfer durability varies widely—sublimation transfers are highly durable on polyester, while vinyl may peel after repeated washing.

Cost-Effectiveness: DTG is economical for small to medium batches. Heat transfers can be cost-effective for very small quantities but require per-transfer material costs that add up quickly.

DTG vs. Sublimation Printing

Sublimation printing offers advantages for specific applications but has material limitations:

Fabric Compatibility: DTG works best on cotton and natural fibers. Sublimation requires polyester or polymer-coated substrates, as the dye-based inks bond only with synthetic materials.

Color Vibrancy: Both methods produce vibrant, full-color prints. Sublimation creates extremely vibrant colors on white polyester fabrics but doesn’t work on dark garments.

Durability: Sublimation offers exceptional durability—the dye becomes part of the fabric itself, creating permanent, fade-resistant prints. DTG provides good durability but may fade gradually over extensive washing.

Print Feel: Both methods maintain excellent fabric hand feel, as inks are absorbed into the fabric rather than sitting on the surface.

Use Cases: DTG dominates the cotton t-shirt and natural fabric apparel market. Sublimation excels for polyester sportswear, activewear, all-over print designs, and hard goods (mugs, phone cases, etc.).

Selecting the Right Fabrics for Optimal DTG Results

Fabric selection significantly impacts DTG print quality, durability, and overall results:

Ideal Fabric Compositions

100% Cotton: The gold standard for DTG printing. Cotton’s natural fibers readily absorb water-based inks, producing vibrant colors, excellent detail, and superior wash durability. Ring-spun cotton provides even better results than open-end cotton due to its smoother surface and tighter weave.

High-Cotton Blends (50-80% Cotton): Cotton-polyester blends with 50% or more cotton content also work well with DTG printing, offering a balance between cotton’s ink absorption properties and polyester’s durability and wrinkle resistance.

Fabrics Requiring Special Consideration

Polyester and Synthetic Fabrics: While possible with specialized pretreatments, polyester’s hydrophobic (water-repelling) nature makes DTG printing more challenging. The water-based inks may not bond as effectively, potentially resulting in reduced vibrancy and durability.

Tri-Blends (Cotton/Polyester/Rayon): These soft, popular fabrics can be printed with DTG but may require adjusted pretreatment formulations and curing parameters to achieve optimal results.

Fabric Color Considerations

Light-Colored Garments (White, Natural, Pastels): Technically don’t require pretreatment for basic prints, though light pretreatment enhances vibrancy and durability. Colored inks print directly with excellent visibility.

Dark-Colored Garments (Black, Navy, Charcoal): Require pretreatment and a white ink underbase to prevent the dark fabric color from showing through and dulling the design colors. The white underbase provides opacity, allowing top colors to appear vibrant and true to the original design.

Professional Tips for Achieving Perfect DTG Prints

Design Optimization Best Practices

Resolution Requirements: Always provide artwork at 300 DPI minimum resolution for professional-quality results. Lower resolution files will appear pixelated or blurry when printed.

File Format Selection: Use PNG files with transparent backgrounds for best results, particularly for designs without rectangular boundaries. High-quality JPEG files work well for photographic images.

Color Mode: Design in RGB color mode, as DTG printers interpret colors in RGB rather than CMYK. Convert Pantone spot colors to RGB equivalents for accurate color matching.

Design Sizing: Consider the printable area of your target garment. Standard adult t-shirts typically accommodate designs up to 14″ x 16″, while youth sizes require smaller dimensions.

Garment Preparation Guidelines

Pre-Press Garments: Always press garments before pretreatment to remove moisture, flatten fabric fibers, and eliminate wrinkles that could affect print quality.

Proper Pretreatment Application: Apply pretreatment evenly across the entire print area using consistent spray patterns or automated pretreatment machines. Under-pretreated areas will show poor ink adhesion; over-pretreated areas may appear shiny or create a visible “box” around the design.

Complete Drying: Ensure pretreatment is completely dry before printing. Moisture remaining in the fabric can cause ink bleeding, color shifting, and poor adhesion.

Printing and Curing Excellence

Proper Print Settings: Adjust ink density, print resolution, and white ink opacity based on fabric type and design requirements. Dark garments require more white ink than light garments.

Adequate Curing: Follow manufacturer recommendations for curing temperature and duration. Under-cured prints will wash out prematurely; over-cured prints may appear yellowed or scorched.

Quality Control: Inspect each print for accuracy, color consistency, proper ink adhesion, and overall quality before final packaging.

DTG Printing for Business: Market Opportunities and Applications

The direct-to-garment printing industry has created diverse business opportunities across multiple sectors:

Print-on-Demand Services

POD businesses leverage DTG printing’s on-demand capabilities to offer vast product catalogs without inventory investment. Leading platforms integrate DTG printing into automated fulfillment workflows, enabling entrepreneurs to launch custom apparel brands with minimal upfront capital. Companies like Teebete provide comprehensive DTG printing solutions that empower businesses to scale efficiently while maintaining quality standards.

Independent Fashion Brands

Emerging designers and independent fashion labels use DTG printing to produce limited-edition collections, test new designs with minimal risk, respond quickly to fashion trends, and maintain creative control over every aspect of production without minimum order requirements that would otherwise be prohibitive with traditional manufacturing.

Corporate Merchandise and Promotional Products

Businesses utilize DTG printing for company-branded apparel, event merchandise and conference giveaways, employee uniforms with personalized details, promotional campaigns requiring quick turnaround, and client gifts featuring custom designs.

Sports Teams and Organizations

DTG technology enables cost-effective production of team uniforms with player names and numbers, fan merchandise and spirit wear, fundraising apparel for schools and non-profits, and tournament and championship commemorative items.

The Future of DTG Printing Technology

The DTG printing industry continues evolving with technological advancements that expand capabilities and improve efficiency:

Technological Innovations

Enhanced Print Speeds: New-generation DTG printers feature improved print head technology and optimized ink delivery systems, significantly reducing print times while maintaining quality.

Expanded Material Compatibility: Ongoing pretreatment and ink formulation research enables effective printing on previously challenging fabrics, including synthetic materials, leather alternatives, and technical textiles.

Hybrid Printing Systems: Emerging hybrid DTG-screen printing machines combine the detail capabilities of DTG with the durability and speed of screen printing, offering versatility for diverse production requirements.

Improved Ink Formulations: Advanced ink chemistry produces more vibrant colors, enhanced wash fastness, better color gamut coverage, and reduced environmental impact through sustainable ingredient sourcing.

Industry Growth Projections

Market research indicates the global direct-to-garment printing market will reach $1,343.6 million by 2035, driven by increasing consumer demand for personalized products, e-commerce growth and print-on-demand services, fashion industry adoption of sustainable practices, and technological improvements making DTG more accessible and cost-effective.

Sustainability Initiatives

The industry is moving toward even more eco-friendly operations through water-based ink innovations with reduced environmental footprint, energy-efficient printer designs consuming less power, closed-loop systems minimizing water waste, and biodegradable pretreatment formulations.

Common DTG Printing Challenges and Solutions

Challenge: Inconsistent Print Quality

Causes: Improper pretreatment application, clogged print heads, incorrect print settings, or poor-quality garments.

Solutions: Establish standardized pretreatment procedures with precise measurement and application. Implement regular printer maintenance schedules including nozzle checks and cleaning cycles. Use high-quality, consistent garment sources. Maintain proper environmental controls (temperature and humidity) in the production area.

Challenge: Poor Wash Durability

Causes: Inadequate curing, improper pretreatment, or low-quality inks.

Solutions: Verify curing equipment maintains correct temperature and duration. Use manufacturer-recommended pretreatment products and application rates. Source premium DTG inks from reputable suppliers. Provide customers with proper garment care instructions.

Challenge: Color Matching Issues

Causes: Uncalibrated monitors, incorrect color profiles, or RGB-to-print translation errors.

Solutions: Use professionally calibrated monitors for design work. Implement proper color management systems with accurate ICC profiles. Create physical sample swatches for critical color matching. Communicate with customers about slight color variations between screen display and printed results.

Challenge: Production Bottlenecks

Causes: Manual pretreatment application, single-printer operations, or inadequate curing capacity.

Solutions: Invest in automated pretreatment machines for consistent application and faster throughput. Consider multiple printer systems for redundancy and increased capacity. Ensure curing equipment matches printer output capacity. Implement efficient workflow management and order batching strategies.

Conclusion: The Transformative Impact of DTG Printing

Direct-to-garment printing has fundamentally transformed the custom apparel industry, democratizing access to high-quality, personalized printing for businesses of all sizes. This technology offers unmatched design flexibility with unlimited colors and intricate detail reproduction, cost-effective small-batch production without prohibitive setup fees, rapid turnaround times enabling responsive, on-demand manufacturing, environmentally sustainable processes using water-based inks and minimal waste, and superior product quality with soft hand feel and photorealistic results.

For businesses considering print-on-demand services, personalized fashion lines, promotional merchandise programs, or custom apparel production, DTG printing provides a low-risk, high-quality solution to bring creative designs to life with unprecedented speed and efficiency. Whether you’re launching a new brand, creating unique gifts, or experimenting with artistic t-shirt designs, DTG printing represents a reliable, cost-effective method that delivers impressive results while maintaining the flexibility to adapt as your business grows.

As technology continues advancing and the market expands, DTG printing will remain at the forefront of the custom apparel revolution, empowering creators, entrepreneurs, and established brands to produce exceptional printed products that meet evolving consumer expectations for quality, customization, and sustainability.

Quick Reference Guide: DTG Printing at a Glance

| Aspect | Key Information |

|---|---|

| Technology Type | Digital inkjet printing directly onto fabric using water-based inks |

| Best For | Small batches (1-100 units), detailed designs, unlimited colors, personalized products |

| Ideal Fabrics | 100% cotton or high-cotton blends (50%+ cotton content) |

| Print Quality | High-resolution, photorealistic, up to 1440 DPI with millions of colors |

| Setup Costs | Minimal to none – no screens or stencils required |

| Production Speed | 2-5 minutes per shirt for standard designs |

| Color Limitations | Unlimited – CMYK process allows millions of color variations |

| Minimum Order | 1 piece (perfect for print-on-demand) |

| Print Durability | 50+ washes with proper curing and care |

| Fabric Feel | Soft and breathable – ink absorbed into fabric |

| Environmental Impact | Eco-friendly – water-based inks, minimal waste, no harmful chemicals |

| Cost Per Unit | $5-15 depending on design complexity and garment type |

| Pretreatment Required | Yes, especially for dark garments |

| Curing Temperature | 320-356°F (160-180°C) for 25-45 seconds |

| File Requirements | 300 DPI minimum, PNG or high-quality JPEG, RGB color mode |

| Main Advantages | No minimums, unlimited colors, fast turnaround, detailed prints, eco-friendly |

| Main Limitations | Best on cotton, higher per-unit cost for bulk orders, gradual fading over time |

| Market Growth | 13% CAGR, projected to reach $3.90 billion by 2030 |

| Competing Methods | Screen printing (bulk), heat transfer (simple designs), sublimation (polyester) |

| Business Applications | Print-on-demand, fashion brands, promotional products, sports teams, custom gifts |

When to Choose DTG Printing

✅ Choose DTG When:

- You need small quantities (1-100 pieces)

- Your design has many colors or intricate details

- You want soft, comfortable prints

- You need fast turnaround times

- You’re printing on cotton or cotton-blend garments

- You value eco-friendly production methods

- You need print-on-demand capabilities

❌ Consider Alternatives When:

- You need 200+ identical pieces (screen printing may be more cost-effective)

- You’re printing on 100% polyester (consider sublimation)

- Your design is simple with 1-3 solid colors (screen printing could work)

- Maximum wash durability is critical (screen printing lasts longer)

- You need all-over printing (sublimation offers full-garment coverage)

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.