Screen Printing vs DTG Which One Is Better for T-Shirts?

Choosing the right printing method for custom t-shirts can dramatically impact your business success, production costs, and customer satisfaction. The debate of screen printing vs DTG has become increasingly important for modern apparel businesses. Whether you’re launching a startup, managing a print-on-demand store, or scaling an established apparel brand, understanding the differences between screen printing and direct to garment (DTG) printing is essential for making informed decisions.

This comprehensive guide explores everything you need to know about screen printing versus DTG, helping you determine which t-shirt printing method aligns best with your business goals, design complexity, and order volumes.

Understanding Screen Printing: The Traditional Powerhouse

Screen printing, also known as silk screening, represents one of the oldest and most trusted garment printing methods in the textile printing industry. This time-tested technique has been delivering vibrant, durable prints for decades.

How Screen Printing Works

The screen printing process involves creating individual stencils (screens) for each color in your design. Ink is pushed through these mesh screens using a squeegee, transferring the design onto the garment. According to RealThread, each color requires a separate screen, which makes the setup process more labor-intensive for complex, multicolor designs.

Here’s the basic workflow:

- Artwork Separation: The design is broken down into individual color layers

- Screen Creation: Each color layer gets its own mesh screen coated with light-sensitive emulsion

- Screen Exposure: The screens are exposed to UV light to harden the design areas

- Ink Application: Ink is pressed through the screen onto the fabric using a squeegee

- Curing: The printed garment is heat-cured to set the ink permanently

Advantages of Screen Printing

Screen printing excels in specific scenarios that make it the preferred choice for many businesses:

Cost-Effective for Bulk Production: Screen printing becomes increasingly economical as order quantities grow, with the per-unit cost decreasing significantly for larger runs. Once screens are created, printing hundreds or thousands of shirts becomes highly efficient. Kornit Digital explains that the more you print, the cheaper it gets per unit, which can be excellent for bulk orders.

Exceptional Durability: Screen printed designs are renowned for their longevity. Screen printing typically offers longer-lasting results, making it an excellent choice for items like sports uniforms or business apparel. The thicker ink layers create prints that withstand repeated washing without significant fading.

Vibrant, Bold Colors: The screen printing technique produces incredibly saturated colors with a substantial, tactile feel. According to RushOrderTees, traditional screen printing uses Plastisol ink which creates designs that pop off the shirt.

Versatility Across Materials: Screen printing works effectively on various fabric types, including cotton, polyester, blends, and even non-fabric items like posters and promotional products.

Limitations of Screen Printing

Despite its strengths, screen printing has notable constraints:

High Setup Costs: Each color in your design requires a separate screen, which can be expensive. Screen setup fees typically range from $30 to $50 per color, making small orders economically unfeasible.

Time-Consuming Setup: The process of creating, exposing, and preparing screens is labor-intensive. This setup time makes screen printing less practical for quick turnarounds or rush orders.

Limited Design Complexity: Screen printing is better suited for simpler designs with fewer colors, as each color requires a separate screen. Photorealistic images, gradients, and intricate details are challenging to reproduce accurately.

Minimum Order Requirements: Due to setup costs, screen printers often require minimum orders of 12-50 pieces to make the job economically viable.

Understanding DTG Printing: The Digital Revolution

Direct to garment printing represents the modern evolution of apparel decoration. This digital printing method has transformed custom t-shirt printing by eliminating many traditional limitations.

How DTG Printing Works

DTG printing involves loading the garment into a specialized machine, which sprays ink in layers directly onto the fabric using inkjet technology. The process resembles how a desktop printer works on paper, but optimized for fabric printing.

The DTG printing workflow includes:

- Pre-Treatment: Northwest Custom Apparel notes that before printing, the garment undergoes a pre-treatment process where a special solution is applied to help the ink bond properly

- Loading: The garment is positioned on the printer platen

- Digital Printing: The design prints directly from computer to fabric in full color

- Heat Pressing: The printed shirt is heat-pressed to cure the ink and ensure durability

Advantages of DTG Printing

Direct to garment printing offers compelling benefits that make it ideal for certain applications:

Perfect for Complex Designs: xTool highlights that DTG outshines screen printing in detail and design complexity, since it prints using tiny dots that keep the design fully close to its digital form with all details intact. The technology handles photorealistic images, intricate logos, and unlimited color palettes with ease.

No Minimum Orders: One of DTG’s most significant advantages is the ability to print single shirts profitably. There are no setup fees or minimum quantities, making it perfect for custom t-shirt printing on demand.

Quick Turnaround Times: With no need for elaborate setup, DTG printing offers faster production times compared to screen printing. This makes it excellent for rush orders and small batch printing.

Unlimited Colors at No Extra Cost: Unlike screen printing where each color adds expense, DTG handles infinite colors in a single pass without additional charges. This makes multicolor designs economically feasible.

Softer Hand Feel: DTG uses water-based inks that absorb into the fabric rather than sitting on top, creating a softer, more comfortable feel compared to traditional plastisol screen printing.

Limitations of DTG Printing

DTG printing also has constraints to consider:

Higher Per-Unit Costs for Large Orders: While DTG eliminates setup fees, the ink costs remain constant per shirt. For dark garments, printing costs can reach significant amounts due to the white underbase requirement, making bulk orders more expensive than screen printing.

Lower Durability on Dark Fabrics: Although DTG technology continues improving, prints on dark garments may not last as long as screen printed alternatives, especially with frequent washing.

Fabric Limitations: DTG performs best on 100% cotton or high-cotton-content blends. Polyester and synthetic fabrics don’t absorb water-based inks as effectively, potentially resulting in less vibrant prints.

Higher Equipment Investment: Professional DTG printers represent a substantial initial investment for small businesses.

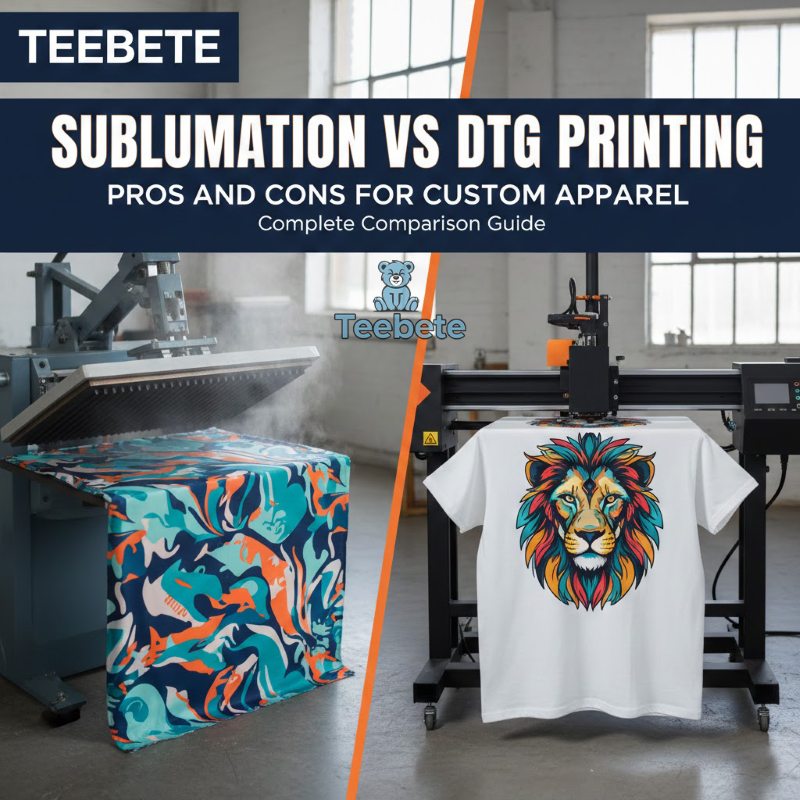

Direct Comparison: DTG vs Screen Printing

Let’s examine how these two printing methods compare across critical decision factors:

Print Quality and Detail

When comparing print quality, both methods excel in different areas.

Fourthwall explains that DTG printing is the best choice for more elaborate designs with fine details, photorealistic imagery, or a wide range of colors. For photographic images, gradient effects, and fine line work, DTG is the clear winner.

Screen printing produces consistently bold, vivid colors with excellent opacity. It’s particularly effective for designs with solid color blocks and simple graphics. The thick ink deposit creates a premium, professional appearance that customers associate with high-quality apparel printing.

Cost Comparison

Understanding the cost structure helps determine which is better screen printing or DTG for t-shirts based on your order volume.

Screen Printing Costs:

- Setup fees: $30-$50 per color

- Per-shirt cost decreases with volume

- Most economical at 50+ pieces

- Additional colors significantly increase setup costs

DTG Printing Costs:

- No setup fees

- White shirts: $0.50-$1.00 per print

- Dark shirts: $1.25-$3.50 per print (including white underbase)

- Pretreatment: approximately $0.50 per shirt

- Cost remains relatively stable regardless of quantity

For a practical example: printing 10 custom shirts with a 4-color design might cost $15-$20 each via screen printing (including setup) versus $10-$15 each via DTG. However, for 100 shirts of the same design, screen printing might drop to $6-$8 per shirt while DTG remains around $8-$12 per shirt.

Durability and Wash Performance

Durability significantly impacts customer satisfaction and repeat business.

Screen printing is renowned for exceptional longevity, with prints that can endure many washes without fading. The thick plastisol ink bonds strongly to fabric and maintains color vibrancy even after 50-100+ wash cycles.

DTG printing offers good durability when properly cared for, though it may fade slightly faster than screen printing. Modern DTG inks have dramatically improved, with high-quality prints lasting through 50+ washes when following proper garment care instructions. The softer feel of DTG prints is a trade-off that many customers prefer despite slightly reduced longevity.

Color Vibrancy and Range

The number of colors in your design significantly impacts method selection.

RealThread notes that DTG’s primary strength lies in its ability to render many colors without incurring additional setup costs for each hue, making it the preferred choice for designs requiring a rich palette, intricate shading, and color gradients.

Screen printing delivers outstanding color saturation and can achieve special effects like metallic inks, glow-in-the-dark, and high-density prints that DTG cannot replicate. However, each additional color increases complexity and cost.

Turnaround Time

Production speed varies significantly between methods.

Screen printing requires substantial setup time for creating and preparing screens. However, once setup is complete, printing hundreds of shirts is remarkably fast. For urgent, small orders, this setup time becomes a disadvantage.

DTG printing eliminates setup time entirely. You can go from digital file to finished shirt in minutes, making it ideal for same-day orders, custom personalization, and rapid prototyping. This speed advantage makes DTG the better choice when you need to print 5-20 shirts quickly.

Environmental Impact

Sustainability increasingly influences business decisions.

DTG is a more sustainable option, using eco-friendly, water-based inks and minimizing waste by printing items on demand, reducing overproduction. The on-demand nature eliminates inventory waste and excess production.

Traditional screen printing often involves plastisol inks containing PVC-based components and requires chemical-based screen cleaning. Water usage and chemical waste are significant concerns. However, some screen printers now use water-based inks as a more environmentally friendly alternative.

When to Choose Screen Printing vs DTG

Understanding when to use screen printing vs DTG helps optimize your production strategy.

Choose Screen Printing When:

- Large Order Quantities: Printing 50+ shirts of the same design makes screen printing cost-effective

- Simple, Bold Designs: Printful recommends screen printing for simple, bold designs that rely on solid colors without any intricate details

- Maximum Durability Needed: Business uniforms, sports teams, and promotional apparel benefit from screen printing’s longevity

- Special Ink Effects Required: Metallic, reflective, or textured inks are only achievable through screen printing

- Budget-Conscious Bulk Orders: When price per unit is the primary concern for large quantities

Choose DTG Printing When:

- Small Batch or Single Items: One-off custom orders or small quantities make DTG economically sensible

- Complex, Detailed Designs: Photorealistic images, gradients, and intricate artwork require DTG’s precision

- Quick Turnaround Essential: When you need finished products in hours rather than days

- Design Testing: When you want to test designs before committing to larger production runs

- Unlimited Color Palettes: When your design includes 10+ colors or full-color photography

- On-Demand Printing: Print-on-demand business models and custom personalization require DTG’s flexibility

Hybrid Approach: Combining Both Methods

Many successful printing businesses, including Teebete, strategically employ both printing techniques to maximize efficiency and profitability.

A hybrid approach allows you to:

- Serve diverse customer needs with appropriate printing solutions

- Optimize costs by selecting the most economical method for each order

- Offer both quick custom orders and bulk production services

- Maintain competitive pricing across all order volumes

- Provide superior quality for both simple and complex designs

For example, you might use DTG for custom, one-off orders and photo-realistic designs while reserving screen printing for recurring bulk orders and simple logo prints.

Making Your Decision: Key Considerations

To determine which printing method lasts longer on t-shirts and suits your specific needs, consider these factors:

Order Volume: Are you typically printing 1-20 shirts (DTG) or 50+ shirts (screen printing)?

Design Complexity: Do your designs feature solid colors (screen printing) or detailed imagery (DTG)?

Budget Constraints: What’s your price sensitivity for small versus large orders?

Turnaround Requirements: Do you need same-day service (DTG) or can you wait for setup (screen printing)?

Target Market: Are customers prioritizing softness and detail (DTG) or durability and boldness (screen printing)?

Business Model: Are you running print-on-demand (DTG), wholesale production (screen printing), or both?

Future Trends in T-Shirt Printing

The garment printing industry continues evolving with technological advancement.

DTG technology improves annually with faster printing speeds, better ink formulations, and enhanced durability. New hybrid printers are emerging that combine DTG precision with screen printing durability.

Sustainability concerns are driving innovation in eco-friendly inks, waterless printing processes, and reduced energy consumption. Both screen printing and DTG printing are adapting to meet environmental standards.

Automation and artificial intelligence are streamlining production workflows, reducing labor costs, and improving quality control for both methods.

Conclusion

The debate of screen printing versus DTG doesn’t have a universal winner—each method excels in different scenarios. Screen printing remains the champion for large-volume orders with simple designs, delivering unmatched durability and cost-effectiveness at scale. DTG printing dominates the custom, small-batch, and complex design market with its flexibility, speed, and detail capabilities.

For businesses and entrepreneurs entering the custom apparel industry, consider starting with DTG if you’re focusing on custom orders, testing designs, or operating a print-on-demand model. Invest in screen printing equipment when you consistently receive bulk orders with simpler designs.

The most successful printing operations often utilize both methods strategically, selecting the optimal technique for each project based on design complexity, order volume, and customer requirements. By understanding the strengths and limitations of both screen printing and DTG printing, you can make informed decisions that maximize quality, minimize costs, and satisfy your customers.

Whether you choose screen printing, direct to garment printing, or a combination of both, the key is matching the right printing method to your specific business needs, design requirements, and target market expectations.

Summary Table: Screen Printing vs DTG Comparison

| Factor | Screen Printing | DTG Printing |

|---|---|---|

| Best for Order Size | 50+ pieces | 1-50 pieces |

| Setup Costs | $30-$50 per color | None |

| Per-Shirt Cost (Small Orders) | $15-$20+ | $10-$15 |

| Per-Shirt Cost (Large Orders) | $6-$8 | $8-$12 |

| Design Complexity | Simple designs, 1-4 colors | Unlimited colors, photorealistic |

| Print Durability | Excellent (100+ washes) | Good (50+ washes) |

| Hand Feel | Thicker, tactile | Soft, breathable |

| Turnaround Time | 5-10 business days | 1-3 business days |

| Color Limitations | Each color adds cost | Unlimited at same cost |

| Best Fabric Types | Cotton, polyester, blends | 100% cotton, high-cotton blends |

| Detail Level | Limited (45 LPI) | High (1200×1200 DPI) |

| Minimum Order | Usually 12-50 pieces | No minimum |

| Environmental Impact | Higher (chemicals, waste) | Lower (water-based, on-demand) |

| Special Effects | Metallic, reflective, textured inks | Standard colors only |

| Initial Equipment Investment | $10,000-$50,000+ | $13,000-$20,000 |

| Ideal Applications | Uniforms, bulk promotional items, simple logos | Custom orders, complex artwork, photo prints |

This comprehensive comparison provides the foundation for making educated decisions about t-shirt printing methods for your business, ensuring you select the approach that maximizes quality, efficiency, and profitability for your specific needs.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.