Sublimation vs DTG Printing Pros and Cons for Custom Apparel

When it comes to custom apparel printing, choosing the right printing method can make or break your business success. Two of the most popular garment printing methods today are sublimation printing and DTG (Direct-to-Garment) printing. Each technique offers unique advantages and comes with its own set of limitations that can significantly impact your production workflow, product quality, and bottom line.

Sublimation printing uses heat to transform dye-based inks into gas that bonds with polyester fabric fibers, while DTG printing applies water-based inks directly onto fabric using advanced inkjet printers. Both methods have become cornerstones of the print-on-demand industry, enabling entrepreneurs and established businesses to create stunning custom designs.

Understanding the difference between sublimation and DTG printing is crucial for anyone in the custom apparel business, whether you’re just starting out or looking to expand your printing capabilities. This comprehensive guide will walk you through everything you need to know about these two printing technologies, helping you make an informed decision for your custom t-shirt printing needs.

Recent advancements in DTG technology have made it particularly effective for complex designs with intricate details and multiple colors, while sublimation continues to dominate the market for all-over prints and polyester-based products.

What is Sublimation Printing?

Sublimation printing, also known as dye sublimation or all-over print, is a unique printing process that uses heat to transform specially formulated dye-based inks from a solid state directly into a gas. This chemical process, called sublimation, allows the ink to bond permanently with the fibers of polyester fabrics or other synthetic materials.

The sublimation printing process begins with creating a design on a computer, which is then printed onto special transfer paper with an absorbent chemical coating using a dye sublimation printer. Once printed, the transfer paper is placed onto the fabric or substrate, and heat and pressure are applied using a heat press. The heat causes the solid ink to transform into gas, which then penetrates deep into the fabric fibers and bonds permanently with the material.

The result is vibrant, high-quality prints that resist cracking and fading, with the ink deeply embedded into the fabric so it feels entirely like a part of the garment.

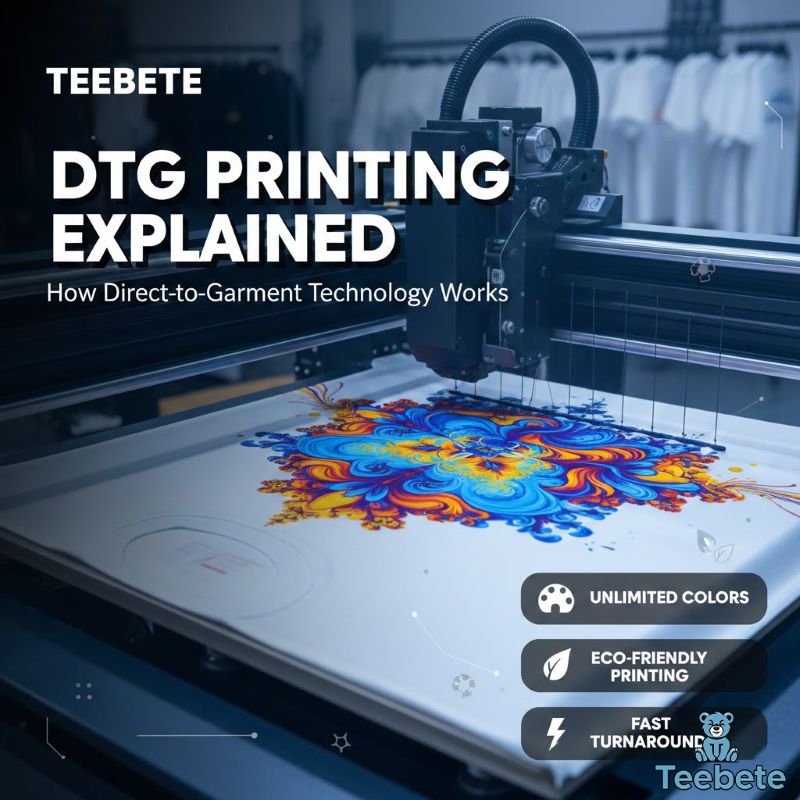

What is DTG Printing?

Direct-to-garment printing, commonly known as DTG printing, is a digital printing technique that works similarly to a standard inkjet printer but for fabrics. DTG printing applies water-based inks directly onto fabric using advanced inkjet printers, making it particularly effective for complex designs with intricate details and multiple colors.

The DTG printing process typically involves three main steps. First, the fabric undergoes a pre-treatment process where a polymer-based solution is applied to help the ink bond properly with the fabric. Next, the garment is loaded onto a flat platen, and the printer sprays the ink directly onto the fabric according to the design specifications. Finally, the printed garment is heat pressed or cured to set the ink and ensure long-lasting durability.

Unlike sublimation, DTG works well on natural fibers like cotton and can be used on both light and dark garments, making it a versatile option for various custom apparel projects.

Sublimation vs DTG Printing: Key Differences

Fabric Compatibility

One of the most significant differences between sublimation and DTG printing lies in fabric compatibility. This factor alone can determine which method is right for your business.

Sublimation Printing: Sublimation can only print designs on polyester fabric, polyester blends (at least two-thirds polyester), or poly-coated materials. The chemical properties of sublimation dyes require synthetic fibers to properly bond and create long-lasting results. This limitation means sublimation won’t work on natural fabrics like 100% cotton, linen, or other natural fibers.

DTG Printing: DTG printing is most effective on natural fibers such as cotton, and can print designs on both light and dark garments. DTG can also work on cotton blends and some synthetic materials, though results may vary. For businesses focused on cotton t-shirts and hoodies, DTG is often the preferred choice.

Print Quality and Durability

Both printing methods can produce high-quality results, but they achieve them differently and with varying degrees of longevity.

Sublimation Print Quality: Sublimation produces extremely vibrant colors, especially on light-colored polyester, with the ink becoming part of the fabric, making colors appear bright, crisp, and highly detailed. Since the dye becomes an integral part of the fabric rather than sitting on top of it, sublimation prints are exceptionally durable and won’t crack or peel.

The permanent bonding makes sublimation ideal for products that will undergo frequent washing or heavy use, such as sportswear and activewear.

DTG Print Quality: DTG also delivers excellent print quality with the ability to reproduce intricate details and photographic images. However, DTG prints sit on top of the fabric and may appear slightly duller, especially on darker fabrics, as DTG printers need a white underbase for dark garments.

In terms of durability, DTG prints typically maintain quality through numerous washes, though proper pretreating, curing process, ink quality, and garment type all affect longevity. While generally less durable than sublimation, proper care can help DTG prints maintain their quality over time.

Color Range and Vibrancy

Sublimation: Sublimation printing allows vibrant colors, multi-color designs, and gradients using four primary colors (cyan, magenta, yellow, and black ink), known as CMYK. However, sublimation has limitations with white and very light colors, as these don’t show well on light-colored fabrics.

Sublimation dyes are semi-transparent, so designs may not be visible against a dark background such as a black shirt. This makes sublimation best suited for white or light-colored polyester garments.

DTG: DTG printing also uses the CMYK color model and can produce unlimited colors in a single design. A DTG printer can reproduce millions of colors, allowing for truly unlimited creative freedom without worrying about increased expenses based on color count. Additionally, DTG can print white ink effectively, making it suitable for dark-colored garments.

Print Area and Design Placement

Sublimation: Sublimation offers edge-to-edge printing, allowing coverage of the entire shirt—front, back, sleeves—with one design, perfect for all-over look or full-pattern graphics. This capability makes sublimation ideal for creating seamless, wrap-around designs that cover the entire garment.

DTG: DTG has a more limited print space, with most printers only allowing a rectangular area, usually on the chest or back. Full-garment printing isn’t possible with standard DTG equipment, limiting design placement options compared to sublimation.

Production Speed and Volume

Sublimation: For small to medium production runs, sublimation can be quite efficient once the setup is complete. However, sublimation printing averages about 60 pieces per hour, compared to screen printing which can produce up to 900 pieces per hour.

DTG: DTG printing is generally slower than other methods, with most common printers completing a shirt every two minutes or so. However, DTG excels at on-demand printing with no minimum order requirements, making it ideal for small batches and custom orders.

Cost Considerations

Sublimation: Sublimation printers can cost anywhere from $1,000 to $15,000, plus a heat press ranging from $500 to $5,000. The lower initial investment makes sublimation more accessible for startups and small businesses.

DTG: DTG printers range from $15,000 to $250,000 or more, representing a significant long-term investment. However, for businesses focused on cotton apparel and small-batch production, the investment can be worthwhile.

Advantages of Sublimation Printing

Exceptional Durability

The primary advantage of sublimation is its unmatched durability. Since the dye becomes part of the fabric itself rather than sitting on top, sublimation prints won’t crack, peel, or fade easily. This makes sublimation ideal for products that will be worn frequently or washed often, such as athletic wear, team uniforms, and activewear.

Unlimited Color Possibilities

Sublimation allows for an unlimited number of colors without increasing production costs. Complex designs with gradients, photographs, and intricate color transitions are all possible with sublimation printing.

All-Over Printing Capability

The ability to print edge-to-edge across an entire garment is a unique advantage of sublimation. This opens up creative possibilities for designers who want to create bold, immersive designs that wrap around the entire product.

Soft Hand Feel

Because the ink becomes part of the fabric, sublimation prints have no texture or thickness. The printed areas feel exactly the same as the rest of the garment, providing exceptional comfort and wearability.

Versatility Beyond Apparel

Sublimation isn’t just for shirts—it works on mugs, mousepads, coasters, phone cases, and other coated items, allowing businesses to expand their product lines beyond apparel.

Lower Initial Investment

Compared to DTG printing, sublimation equipment requires a smaller upfront investment, making it more accessible for entrepreneurs and small businesses just starting in the custom printing industry.

Disadvantages of Sublimation Printing

Material Restrictions

The main disadvantage is that sublimation can only print designs on polyester fabric, polyester blends, or poly-coated materials. This excludes popular natural fibers like cotton, which many customers prefer for comfort and breathability.

Limited to Light-Colored Fabrics

Sublimation is not suited for dark fabrics as sublimation dyes are semi-transparent and designs may not be visible against dark backgrounds. This significantly limits color options for base garments.

White Color Limitations

Sublimation struggles with white and very light colors in designs. Since the process works by dyeing the fabric, white areas simply show the original fabric color, which can be problematic for certain design types.

UV Sensitivity

Sublimation ink is UV sensitive, meaning printed designs can fade over time if exposed to direct sunlight. This may be a concern for outdoor products or garments that will be worn frequently in sunny conditions.

Longer Production Process

The sublimation process requires multiple steps—printing onto transfer paper, positioning the transfer, heat pressing, and potentially cutting and sewing. This can make it slower for some production workflows compared to direct printing methods.

Advantages of DTG Printing

Works on Natural Fibers

DTG works well on natural fibers like cotton and can be used on both light and dark garments. This versatility is crucial for businesses serving customers who prefer cotton apparel for its comfort and breathability.

Perfect for Small Orders

DTG printing has minimal setup costs and no minimum order requirements, making it incredibly cost-effective for printing just a few shirts or even a single customized item. This makes DTG ideal for print-on-demand businesses and personalized products.

Exceptional Detail Reproduction

DTG excels at reproducing complex, photo-realistic designs with fine details and smooth color transitions. The technology can handle millions of colors without additional setup or cost increases.

Easy to Use

Once properly set up and calibrated, DTG printers are relatively straightforward to operate. Designs can be sent directly from a computer to the printer without creating screens or transfers, streamlining the production process.

Environmental Benefits

DTG’s water-based inks are generally seen as more eco-friendly, producing less waste compared to traditional screen printing methods. This can be an important selling point for environmentally conscious customers.

Print-on-Demand Friendly

DTG’s flexibility for on-demand printing is a game-changer for custom orders, like personalized t-shirts for events or small batches for niche markets, with no minimum order quantity.

Disadvantages of DTG Printing

Fabric Limitations

DTG printing works best on 100% cotton or high-cotton blend fabrics and may not be suitable for certain synthetic fabrics or materials with special coatings. This limits options for polyester-based athletic wear and performance fabrics.

Pre-Treatment Requirements

Some fabrics require pre-treatment before printing to ensure that the ink adheres properly, adding to overall production time and cost. The pre-treatment process can also leave visible marks or stains on some garments, particularly on darker colors.

Limited Print Area

Most standard DTG printers have a flat platen, meaning designs are confined to flat surfaces on the garment, making it challenging to print across seams or around sleeves. This restriction limits creative possibilities compared to sublimation’s all-over printing capability.

Durability Concerns

While DTG prints can last a long time with proper care, they are generally less durable than sublimation prints. Dark printed clothes may crack over time due to the white background layer, where white ink is used.

Higher Equipment Costs

The initial investment for DTG equipment is substantially higher than sublimation. Additionally, DTG printers require regular maintenance, including cleaning print heads and replacing ink cartridges, which are both costly and time-consuming.

Color Matching Challenges

DTG printers often struggle with exact color matching, with color output varying depending on fabric type, pretreatment processes, and specific inks used. This can be problematic for brands requiring precise color fidelity.

Slower Production Speed

Printing on garments using DTG can take longer compared to some other methods, especially when printing larger designs across the entire surface. For high-volume production, this can become a bottleneck.

Which Printing Method is Best for Your Business?

Choosing between sublimation and DTG printing depends on several factors specific to your business model, target market, and product offerings.

Choose Sublimation If:

- You primarily work with polyester fabrics and synthetic materials

- You want to create all-over print designs with seamless edge-to-edge coverage

- Maximum durability is a priority (athletic wear, uniforms, frequently washed items)

- You prefer vibrant, photo-realistic colors on light-colored garments

- You want to expand beyond apparel into hard goods like mugs and phone cases

- You’re starting with a limited budget and want lower initial equipment costs

- Your target market prefers performance fabrics over natural fibers

Choose DTG If:

- You focus on cotton and natural fiber apparel

- You need to print on both light and dark colored garments

- You specialize in small batch production or print-on-demand services

- You want to offer personalized, one-off custom products

- Your designs include white or very light colors as key elements

- You need quick turnaround times for simple designs

- Your customers prioritize the soft feel and breathability of cotton

Consider Both If:

Many successful custom apparel businesses, like Teebete and others in the industry, use both printing methods to maximize their product offerings and serve a wider customer base. By investing in both technologies, you can:

- Offer customers the best printing method for their specific needs

- Expand your product catalog to include both cotton and polyester items

- Provide options for different budget levels and durability requirements

- Serve diverse markets from casual wear to performance apparel

- Maximize flexibility in design placement and product types

Frequently Asked Questions

Is sublimation printing better than DTG?

Neither method is universally “better”—each excels in different areas. Sublimation offers superior durability and all-over printing capabilities but only works on polyester and light-colored fabrics. DTG provides versatility with natural fibers and works on dark colors but has limited print area and potentially lower durability. The best choice depends on your specific fabric preferences, design requirements, production volume, and target market.

Which method is best for t-shirt printing?

For cotton t-shirts, DTG is generally the better choice as it works excellently on natural fibers and can print on both light and dark colors. For polyester t-shirts or athletic wear, sublimation is preferred due to its exceptional durability and vibrant colors. If you want all-over printed designs that cover the entire garment, sublimation is the only practical option. For small custom orders with detailed designs on cotton, DTG is ideal.

What are the disadvantages of sublimation printing?

The main disadvantages include material limitations (only works on polyester or poly-coated items), inability to print on dark-colored fabrics, challenges with white and light colors in designs, UV sensitivity that can cause fading in direct sunlight, susceptibility to white creasing during production, and a slower, multi-step production process. Additionally, the specialized equipment and materials required can have ongoing costs, and there’s no option for natural fabric enthusiasts who prefer cotton comfort.

What are the disadvantages of DTG printing?

DTG’s primary drawbacks include higher initial equipment costs ($15,000+), fabric limitations (works best on cotton but struggles with polyester), pre-treatment requirements that add time and potential staining, limited print area that restricts design placement, potential for prints to crack or fade over time especially on dark garments, significant maintenance requirements for print heads, difficulty achieving exact color matches, slower production speeds compared to methods like screen printing, and higher per-unit costs for large production runs.

Can I print white designs with these methods?

DTG can print white ink effectively, making it excellent for white designs on dark garments. Sublimation, however, cannot produce white—any white areas in your design will simply show the original fabric color. This is why sublimation works best on white or light-colored polyester where the base fabric serves as the “white” in the design.

How do I care for sublimation vs DTG printed garments?

For sublimation prints, you can typically wash normally as the dye is permanently bonded to the fabric fibers, though avoiding prolonged direct sunlight will prevent UV-related fading. For DTG prints, washing in cold water, using gentle detergents, turning garments inside out, and avoiding excessive heat when drying will help maintain print quality and extend the life of the design. Both methods benefit from air drying or low heat tumble drying.

Which method is more environmentally friendly?

DTG printing is generally considered more eco-friendly due to its water-based inks and minimal waste production. The process doesn’t require water during printing (unlike traditional methods), though pre-treatment does involve chemicals. Sublimation uses specialized dyes and the heat transfer process consumes energy, but it also produces minimal waste. Both methods are more environmentally conscious than traditional screen printing, which uses harsh chemicals and produces significant setup waste.

Can I use both methods in my business?

Absolutely. Many successful print-on-demand and custom apparel businesses use both sublimation and DTG printing to offer maximum variety to their customers. This approach allows you to recommend the best printing method for each specific project based on fabric type, design requirements, quantity, and budget. Having both capabilities positions your business to serve a broader market and capitalize on the strengths of each technology.

Summary Table: Sublimation vs DTG Printing

| Factor | Sublimation Printing | DTG Printing |

|---|---|---|

| Best Fabrics | Polyester, polyester blends (65%+ polyester), poly-coated materials | Cotton, cotton blends, natural fibers |

| Fabric Colors | White and light colors only | Works on both light and dark colors |

| Print Durability | Exceptional—won’t crack, peel, or fade easily | Good with proper care—15-40 washes typically |

| Print Area | Edge-to-edge, all-over printing possible | Limited to flat platen area (typically 16″x20″) |

| Color Range | Unlimited colors using CMYK | Unlimited colors using CMYK |

| White Ink | Cannot print white | Can print white effectively |

| Print Quality | Vibrant, photo-realistic on light polyester | Excellent detail, slightly duller on dark fabrics |

| Hand Feel | Soft, no texture—print is part of fabric | Soft, slight texture on heavily inked areas |

| Initial Investment | $1,000-$15,000 for printer + $500-$5,000 for heat press | $15,000-$250,000+ |

| Setup Time | Moderate—requires printing transfer then heat pressing | Quick—direct to garment printing |

| Best for Volume | Small to medium batches | Small batches, one-offs, print-on-demand |

| Production Speed | ~60 pieces per hour | ~30 pieces per hour (varies by design) |

| Pre-treatment | Not required | Required for most garments, especially dark colors |

| Product Versatility | Apparel + hard goods (mugs, phone cases, etc.) | Primarily apparel |

| Environmental Impact | Moderate—specialized inks and heat process | Better—water-based inks, less waste |

| Ideal Use Cases | Athletic wear, uniforms, all-over prints, polyester products | Custom cotton t-shirts, small orders, personalized gifts |

| Maintenance | Low to moderate | High—frequent print head cleaning required |

Conclusion

The choice between sublimation vs DTG printing ultimately comes down to understanding your specific business needs, target market preferences, and product offerings. Both garment printing methods have earned their place in the custom apparel printing industry by excelling in different areas.

Sublimation printing offers unbeatable durability, vibrant colors, and the unique ability to create all-over printed designs on polyester garments and hard goods. Its lower equipment costs make it accessible for startups, while its fade-resistant, crack-proof prints make it ideal for athletic wear and frequently washed items.

DTG printing provides unmatched versatility for cotton and natural fiber apparel, works on both light and dark colors, and excels at producing detailed, photo-realistic designs for small batches and print-on-demand applications. Despite higher equipment costs, its flexibility and eco-friendly water-based inks make it a popular choice for custom t-shirt printing businesses.

Many successful businesses in the custom apparel industry strategically use both printing technologies to maximize their product offerings and serve diverse customer needs. By understanding the pros and cons of sublimation printing for apparel alongside DTG’s strengths and limitations, you can make informed decisions about which printing technology aligns best with your business goals.

Whether you choose sublimation, DTG, or both, the key to success lies in matching the right printing method to the right application—considering fabric type, design complexity, production volume, durability requirements, and customer preferences. With this knowledge, you’re well-equipped to select the best printing method for custom apparel that will help your business thrive in the competitive custom printing market.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.