Why DTG Printing Is a Game-Changer for Personalized T-Shirts

The custom apparel industry has witnessed a remarkable transformation over the past two decades, driven largely by technological innovations that make personalized clothing more accessible than ever. At the forefront of this revolution stands direct to garment printing, a digital textile printing method that has fundamentally changed how we approach custom t-shirt printing. For businesses like Teebete and individual creators alike, understanding this technology isn’t just about keeping up with trends—it’s about unlocking new possibilities for creative expression and business growth.

Understanding DTG Printing Technology

Direct to garment printing operates on a principle that’s surprisingly similar to your home inkjet printer, but instead of paper, it prints directly onto fabric. This inkjet technology allows designs to be applied straight onto various textiles and garments, creating a seamless integration between the digital design and the physical product.

The process begins with a digital file containing your design. Unlike traditional screen printing, which requires creating physical screens for each color, DTG printing technology translates your artwork directly into instructions for specialized print heads. These print heads contain thousands of microscopic nozzles, each smaller than a human hair, ensuring fine details are captured with remarkable accuracy.

The technology relies on water-based textile inks that work exceptionally well with natural fibers. When the ink is jetted onto the fabric, it penetrates the fibers rather than sitting on top of the material, creating prints that feel soft to the touch and move naturally with the garment.

The DTG Printing Process Explained

Creating a high-quality DTG print involves several crucial steps that work together to ensure durability and vibrancy:

Pretreatment Application

Before any ink touches the fabric, the garment undergoes pretreatment—a critical step that many newcomers to garment decoration overlook. Pretreatment involves applying a chemical solution to the garment before printing, which creates a smooth, ink-receptive surface. This is especially important for dark-colored garments, where a white underbase is necessary to make colors pop.

The pretreatment serves multiple functions: it helps flatten loose fibers to provide a smoother substrate, strengthens the bond between garment fibers and the pigmented inks, and promotes chemical reactions with the inks that enhance overall print quality.

Digital Printing

Once the pretreatment has been applied and heat-pressed into the fabric, the garment is positioned onto a specialized platen system designed to hold it perfectly flat. The printer then jets water-based ink directly onto the fabric in precise patterns, building up the image layer by layer.

For dark garments, the printer first applies a white ink underbase, then prints the CMYK colors over it. This ensures that your design maintains its intended vibrancy regardless of the garment color.

Curing and Finishing

The final step in the DTG printing process involves curing the print. This is done using either a heat press or a conveyor dryer, applying the right amount of pressure at the correct temperature for a specific duration. When done properly, the result is a beautiful garment that will stand up to years of regular wash and wear.

Why DTG Printing Excels for Personalized T-Shirts

Unmatched Detail and Color Capabilities

One of the most compelling advantages of DTG printing for custom apparel printing is its ability to handle complex designs with extraordinary precision. The method can handle complex designs with a wide range of colors, gradients, and fine details that would be difficult or impossible with other methods like screen printing.

This capability opens doors for designers who want to create photorealistic prints, intricate patterns, or artwork with subtle color transitions. Whether you’re printing a detailed photograph, a watercolor-style illustration, or a design with hundreds of colors, DTG technology delivers results that maintain the integrity of your original artwork.

The technology excels at reproducing:

- High-resolution photographs and portraits

- Gradient color transitions and shading effects

- Fine lines and intricate patterns

- Designs with unlimited color palettes

- Text in small font sizes with crisp edges

Perfect for Small Batch Printing and Print on Demand T-Shirts

Traditional screen printing requires significant setup time and cost for each design, making it economically viable only for larger orders. DTG printing fundamentally changes this equation. DTG printing is exceptionally well-suited for small to medium-sized orders, with efficiency that shines when dealing with low-volume production or one-off prints.

This flexibility makes DTG printing the ideal choice for:

- Print-on-demand businesses that produce items only after receiving orders, eliminating inventory risk

- Custom merchandise for events, special occasions, or limited edition releases

- Test marketing new designs before committing to larger production runs

- Personalized gifts with unique, one-of-a-kind designs

- Sample creation for designers and brands to evaluate concepts before mass production

For Teebete, this capability means we can offer our customers the freedom to order exactly what they need, when they need it, without forcing them into minimum order quantities that lead to excess inventory.

Superior Softness and Fabric Integration

The tactile quality of a printed garment significantly impacts customer satisfaction. DTG printing offers a distinct advantage in this area. DTG inks are water-based, resulting in a softer feel on the fabric, especially on light-colored garments where minimal ink is required.

Unlike some printing methods where the design sits noticeably on top of the fabric, DTG ink soaks into the fibers themselves. This creates prints that breathe with the fabric and maintain the natural drape and comfort of the garment. For light-colored shirts, the result is often described as a “vintage” feel where the design becomes one with the shirt rather than feeling like an addition to it.

Rapid Turnaround Times

In today’s fast-paced market, speed matters. DTG printing shines in terms of speed for small to medium-sized orders due to minimal setup time. While screen printing requires creating screens, mixing inks, and setting up the press—a process that can take hours—DTG printing can begin production almost immediately after receiving a digital file.

This advantage translates to:

- Faster delivery times for customers

- Ability to respond quickly to trending topics or time-sensitive events

- More efficient production scheduling

- Reduced lead times from concept to finished product

For businesses operating in the on-demand printing space, this speed advantage is often the difference between capturing a market opportunity and missing it entirely.

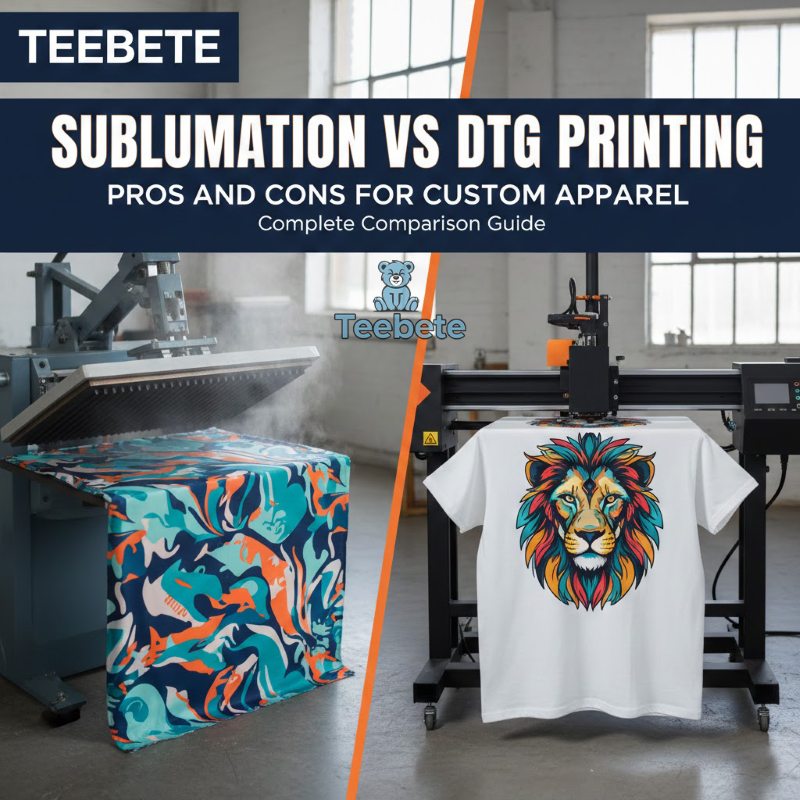

DTG Printing vs Screen Printing: Making the Right Choice

Understanding when to use DTG printing versus screen printing is essential for optimizing your custom t-shirt printing operations. Each method has distinct strengths that make it ideal for specific applications.

Design Complexity and Color Count

DTG printing is the best choice for more elaborate designs with fine details, photorealistic imagery, or a wide range of colors, as there are no limitations on how detailed the design can be or on the number of colors used.

Screen printing, by contrast, requires creating a separate screen for each color in your design. This makes it more cost-effective for simpler designs with fewer colors, particularly bold graphics, logos, or text-based designs with solid color areas.

Order Volume Considerations

The economic equation shifts dramatically based on order size. Screen printing is better for larger orders with fewer colors, as each color requires a separate screen which can be both time consuming and costly for designs with many colors.

For orders exceeding 100 pieces of the same design, screen printing typically becomes more cost-effective. The initial setup costs are amortized across the larger quantity, bringing the per-unit cost down significantly. However, for orders under 25 pieces or for multiple different designs in small quantities, DTG printing maintains its cost advantage.

Fabric Type and Color

DTG printing performs optimally on 100% cotton and cotton-blend fabrics. The water-based inks bond most effectively with natural fibers, creating durable, vibrant prints. While the technology has expanded to include polyester printing capabilities in some systems, cotton remains the gold standard for DTG applications.

Screen printing offers greater versatility across fabric types, working well on cotton, polyester, blends, and various specialty materials. It also handles both light and dark garments without significant process changes, whereas DTG requires additional pretreatment steps for dark fabrics.

Print Durability and Longevity

Both methods can produce durable prints when executed properly, but they age differently. The industry standard for printed clothing is 50 washes, though many agree that DTG prints will last longer than that, with direct-to-garment prints tending to last the life of the garment.

Screen printing with plastisol inks creates a thicker ink layer that sits on top of the fabric. This can lead to cracking over time, especially in high-flex areas. However, when properly cured, screen prints are renowned for their longevity and can maintain their appearance through hundreds of wash cycles.

DTG prints, using water-based inks that integrate into the fabric, resist cracking but may experience a phenomenon called fibrillation, where fabric fibers gradually rise through the print over many washes, potentially creating a slightly faded appearance. Proper care significantly extends the life of DTG prints.

Environmental Considerations: Eco-Friendly Printing Practices

The apparel industry faces increasing scrutiny regarding its environmental impact, and printing methods play a significant role in a garment’s overall sustainability profile. DTG printing technology offers several ecological advantages that align with growing consumer demand for environmentally responsible products.

DTG printing reduces water consumption, waste generation, and chemical usage, while the ability to print on demand minimizes overproduction and inventory waste. This on-demand printing model fundamentally changes the waste equation in apparel production, eliminating the need to manufacture and store inventory that may never sell.

Traditional screen printing involves substantial water usage for screen cleaning, along with chemical waste from the screen-making process and plastisol inks that contain PVC-based components. DTG printing uses water-based ink printing that contains fewer harmful chemicals, reducing health hazards for workers and consumers alike.

At Teebete, we recognize that sustainability isn’t just about the printing method—it’s about the entire production and consumption cycle. By enabling small batch printing and eliminating minimum order quantities, DTG technology helps brands avoid overproduction, one of the fashion industry’s most significant environmental challenges.

Maximizing DTG Print Quality and Durability

Achieving consistently excellent results with DTG printing requires attention to several critical factors throughout the production process.

Choosing the Right Fabrics

Fabric selection profoundly impacts both print quality and longevity. High-quality, 100% cotton garments tend to hold the print better, maintaining color crispness and durability, with proper pretreatment and curing being essential for long-lasting results.

The fabric’s thread count, weave tightness, and pre-washing status all influence how well the ink bonds with the material. Pre-washed garments help prevent shrinkage that could distort your design, while tighter weaves provide a smoother printing surface that enhances detail reproduction.

Proper Pretreatment Techniques

Pretreatment is often described as the “make or break” step in DTG printing. The correct amount of pretreatment solution must be applied evenly across the print area, then heat-pressed to lock it into the fabric before printing begins.

Too little pretreatment results in poor ink adhesion and washed-out colors. Too much creates a stiff hand feel and can cause the ink to sit on top of the solution rather than penetrating the fabric. Finding the optimal balance requires calibration for each fabric type and color.

Ink Quality and Equipment Maintenance

High-quality inks, often used with a bright underbase that’s pretreated, enhance the vibrancy and durability of the print, ensuring that colours remain vivid and the design stays intact over many washes.

Equally important is the printing equipment itself. Daily use and regular maintenance are essential for DTG printers, including agitating white ink to prevent sedimentation, cleaning print heads, and ensuring proper humidity levels to avoid nozzle clogs.

Maintaining optimal environmental conditions in your printing space is crucial. Humidity between 50-60% and temperature between 70-80°F are critical for optimal DTG printing, as low humidity can cause ink to dry prematurely, clogging print heads and affecting quality.

Curing Parameters

The curing process must be precisely controlled to ensure proper ink adhesion and durability. Temperature, pressure, and duration must all be calibrated according to the ink manufacturer’s specifications. Under-curing results in prints that wash out prematurely, while over-curing can damage the fabric or cause discoloration.

Care Instructions for Long-Lasting DTG Prints

Even the highest-quality DTG print won’t reach its full longevity potential without proper care. Educating customers about garment care is an essential part of delivering value in the custom apparel printing business.

Washing Guidelines

To extend the life of DTG prints, it’s important to wash them in cold water, ideally handwashing, using gentle detergents and avoiding high-heat drying, with air drying recommended to prevent the ink from breaking down.

Turning garments inside out before washing protects the printed design from friction against other clothes in the washing machine. This simple step significantly extends print life by minimizing abrasion on the design surface.

Drying and Storage

High heat is the enemy of DTG prints. While tumble drying is possible on low heat settings, air drying provides the gentlest treatment and maximizes print longevity. Direct sunlight exposure should be minimized, as UV rays can gradually fade colors over time.

When ironing is necessary, always place the garment inside out or use a pressing cloth between the iron and the design. Direct heat contact can damage or discolor DTG prints.

Detergent Selection

Harsh detergents and bleach-based products can break down water-based inks over time. Mild, color-safe detergents preserve both the fabric and the print, maintaining vibrancy through dozens of wash cycles.

The Economics of DTG Printing for Your Business

Understanding the cost structure of DTG printing helps businesses make informed decisions about when to use this technology versus alternative methods.

Initial Investment and Operating Costs

DTG printers represent a significant capital investment, with professional-grade machines ranging from $5,000 to well over $100,000 depending on capabilities and production speed. However, for businesses focused on small-batch production and customization, this investment often pays for itself through the ability to serve markets that screen printing cannot economically address.

Operating costs for DTG printing include ink, pretreatment solution, garments, and equipment maintenance. The per-print cost for DTG tends to be higher than screen printing for large quantities but significantly lower for small orders due to minimal setup requirements.

Pricing Strategies

The cost-effectiveness of DTG printing for one-off designs makes it particularly attractive for print-on-demand business models. By eliminating inventory risk and setup costs, businesses can offer competitive pricing on single items while maintaining healthy margins.

For customers, DTG printing often represents the best value for:

- Orders under 25 pieces

- Designs with more than 4-5 colors

- Photo-realistic or highly detailed artwork

- Quick turnaround requirements

- Testing new designs before larger production runs

Market Growth and Opportunities

Consumer demand for personalization continues to surge, with businesses recognizing the value proposition of unique products. The market for customized apparel shows strong growth trends, reflecting fundamental shifts in consumer preferences toward individual expression.

This growth trajectory reflects fundamental shifts in consumer behavior. Today’s customers increasingly value uniqueness and personal expression over mass-produced uniformity. DTG technology provides the perfect tool to serve this evolving market demand.

Common Applications of DTG Printing

The versatility of DTG printing makes it suitable for a diverse range of applications across multiple industries.

E-commerce and Print-on-Demand

Online platforms have embraced DTG printing as the backbone of their business models. Print-on-demand businesses produce items only upon order placement, reducing inventory risk, while online platforms and stores can offer vast product selections without holding stock.

This model has democratized the custom apparel industry, allowing anyone with design skills and entrepreneurial spirit to launch a clothing brand without significant capital investment.

Event and Promotional Merchandise

From corporate events to music festivals, DTG printing enables organizers to create custom merchandise that captures the unique character of their event. Promotional and event merchandise benefits from DTG’s ability to print complex logos and images for event uniforms and customer giveaways.

The quick turnaround times mean last-minute design changes or rush orders can be accommodated, providing flexibility that traditional printing methods cannot match.

Artist and Designer Collaborations

Artists can reproduce their work vividly and authentically on clothing through wearable art applications, transforming canvases and digital artwork into wearable pieces that maintain the integrity and detail of the original creation.

This application has opened new revenue streams for visual artists while providing consumers with truly unique, artistically significant apparel.

Fashion Brands and Sampling

Major fashion brands use DTG to quickly produce prototype garments before mass production, allowing designers to evaluate color combinations, placement, and overall aesthetic before committing to large manufacturing runs.

This sampling capability reduces waste and enables more agile design processes where ideas can be tested and refined rapidly.

Overcoming Common DTG Printing Challenges

While DTG printing offers numerous advantages, practitioners must navigate certain challenges to achieve consistent, high-quality results.

Dark Garment Printing

Printing on dark-colored fabrics requires additional steps compared to light garments. The white ink underbase must be sufficiently opaque to prevent the garment color from showing through, yet not so heavy that it creates an unpleasantly thick hand feel.

Achieving the right balance requires experience and proper equipment calibration. Pretreatment becomes even more critical on dark garments, as it provides the surface for the white ink to adhere properly.

Polyester and Synthetic Fabrics

While DTG printing has expanded beyond its original cotton-only limitations, synthetic fabrics still present challenges. Polyester’s lower absorbency means inks may not bond as effectively, potentially affecting both color vibrancy and wash durability.

Some modern DTG printers have developed specialized processes and inks for polyester printing, but cotton and cotton blends remain the most reliable substrate for consistently excellent results.

Production Speed for Large Orders

DTG printing’s strength in small-batch production becomes a limitation when order volumes increase significantly. The time required to print each garment individually means that for orders exceeding 100 pieces of the same design, screen printing often becomes more efficient and cost-effective.

Understanding these thresholds helps businesses develop hybrid approaches, using DTG for customization and variety while leveraging screen printing for high-volume runs.

The Future of DTG Printing Technology

The DTG printing industry continues to evolve rapidly, with ongoing innovations addressing current limitations and expanding capabilities.

Since its early 2000s introduction, DTG technology has improved in speed, ink efficiency, and print quality, with modern printers producing sharper images at lower costs and faster speeds compared to older models.

Emerging developments include:

- Advanced ink formulations that expand substrate compatibility and improve wash durability

- Faster print heads that increase production throughput without sacrificing quality

- Improved pretreatment systems that simplify the process and enhance consistency

- Hybrid machines that combine DTG capabilities with other printing technologies like DTF (Direct-to-Film)

- AI-assisted color matching and quality control systems

These innovations continue to enhance DTG printing’s competitiveness across a broader range of applications, making it an increasingly attractive option for diverse garment decoration needs.

Why Teebete Chooses DTG Printing

At Teebete, our commitment to DTG printing technology stems from a fundamental belief in empowering creativity without compromise. We’ve witnessed firsthand how this technology transforms ideas into reality, enabling our customers to bring their unique visions to life without the constraints that traditional printing methods impose.

The flexibility to produce single pieces or small batches means our customers can test designs, create limited editions, or produce exactly the quantity they need without waste or excess inventory costs. The ability to reproduce intricate designs with unlimited colors opens creative possibilities that would be economically unfeasible with screen printing.

Our investment in state-of-the-art DTG equipment, combined with rigorous quality control processes and proper garment care education, ensures that every piece leaving our facility meets the highest standards for both visual impact and durability. We understand that each printed garment represents someone’s creative vision or business brand, and we treat that responsibility seriously.

The environmental benefits of on-demand production align with our values and the expectations of our increasingly eco-conscious customer base. By eliminating overproduction and using water-based inks with fewer harmful chemicals, we contribute to a more sustainable apparel industry.

Frequently Asked Questions

What are the downsides of DTG printing?

DTG printing has several limitations to consider. The technology works best on 100% cotton and cotton-blend fabrics, with synthetic materials like polyester presenting challenges for ink adhesion and color vibrancy. The per-unit cost tends to be higher than screen printing for large orders, making it less economical for bulk production of identical designs. Dark-colored garments require additional pretreatment steps and white ink underbase, which adds complexity and can affect the hand feel compared to prints on light garments. Production speed for large quantities is slower than screen printing, as each garment must be printed individually. Finally, while modern DTG prints are quite durable, they may show signs of aging sooner than screen prints under harsh washing conditions, though proper care significantly extends their lifespan.

Which t-shirt printing method is best?

The “best” printing method depends entirely on your specific needs and priorities. DTG printing excels for small-batch orders, designs with many colors or photorealistic details, quick turnaround requirements, and on-demand production models. It’s ideal for e-commerce businesses, custom merchandise, and situations where design variety matters more than volume. Screen printing remains superior for bulk orders over 100 pieces, simple designs with few colors, printing on diverse fabric types including synthetics, and situations requiring maximum durability and the lowest per-unit cost. Many successful businesses use both methods strategically, leveraging DTG for customization and variety while using screen printing for high-volume runs. Consider your order volumes, design complexity, fabric types, budget constraints, and timeline when making your decision.

What are the benefits of DTG printing?

DTG printing offers numerous compelling advantages for modern apparel production. The technology handles unlimited colors and complex designs with photorealistic detail that screen printing cannot economically match, including gradients, fine lines, and intricate patterns. It requires no minimum order quantities, making single-piece production economically viable and enabling true on-demand manufacturing. Setup time is minimal compared to screen printing, allowing for faster turnaround times and more agile responses to market demands. The water-based inks create a soft hand feel, especially on light garments, and contain fewer harmful chemicals than traditional plastisol inks, making them more environmentally friendly. The digital nature of the process means designs can be easily modified, tested, and personalized without creating new physical screens. Finally, the reduced waste from on-demand production and the elimination of screen-making waste contribute to a more sustainable production model.

How long do DTG prints last?

When properly executed and cared for, DTG prints can last the lifetime of the garment itself, typically maintaining quality through 50 or more wash cycles, with some lasting considerably longer. The actual lifespan depends on several critical factors: the quality of inks and equipment used, proper pretreatment application, correct curing temperature and duration, fabric quality and composition, and most importantly, how the garment is cared for. To maximize longevity, wash DTG-printed garments inside out in cold water with mild detergent, avoiding bleach and harsh chemicals. Air drying is ideal, but if using a dryer, select low heat settings. The fabric color also affects durability—prints on light-colored garments typically last longer than those on dark garments, which require white ink underbase. High-quality 100% cotton fabrics hold prints better than blends or synthetics. While DTG prints may not match the extreme durability of well-executed screen prints, they offer excellent longevity for most applications when quality standards are maintained throughout production.

Is DTG printing environmentally friendly?

DTG printing offers several environmental advantages over traditional printing methods, though no manufacturing process is entirely without impact. The water-based inks used in DTG printing contain fewer harmful chemicals compared to the plastisol inks commonly used in screen printing, reducing health risks for workers and minimizing toxic chemical release. The on-demand production model fundamentally reduces waste by eliminating the need to produce and store inventory that may never sell, addressing one of the fashion industry’s most significant environmental challenges—overproduction. DTG printing consumes less water than screen printing, which requires substantial water usage for screen cleaning and reclaiming. The elimination of screen-making processes reduces chemical waste from emulsions, cleaning solutions, and screen disposal. However, DTG printing does consume electricity for equipment operation and produces some waste from ink cartridges, pretreatment solutions, and equipment cleaning. The environmental impact also depends on the garment itself—organic cotton garments printed with DTG technology represent a more sustainable choice than conventional materials. Overall, when combined with responsible sourcing and proper waste management, DTG printing represents a more environmentally conscious choice for custom apparel production.

Can DTG printing work on all fabric types?

DTG printing performs optimally on 100% cotton and cotton-blend fabrics, where the water-based inks bond most effectively with the natural fibers. Cotton-blend garments (typically 50% cotton or higher) can produce excellent results, though pure cotton generally yields the best color vibrancy and durability. Some modern DTG printers have expanded capabilities for polyester printing, though results may vary compared to natural fibers—synthetic materials’ lower absorbency can affect color saturation and wash durability. Fabrics with tight weaves and smooth surfaces produce sharper prints than loosely woven or highly textured materials. Dark-colored fabrics of any type require pretreatment and white ink underbase, adding complexity but enabling successful printing. Performance fabrics and technical textiles with moisture-wicking or water-resistant treatments may resist ink adhesion, making them challenging for DTG printing. Before committing to large orders on unfamiliar fabric types, always request test prints to evaluate quality, color accuracy, and hand feel on the specific material you intend to use.

What file format is best for DTG printing?

High-resolution PNG files with transparent backgrounds work best for most DTG printing applications, as they preserve image quality while allowing designs to be placed on any garment color without unwanted background boxes. For photographic prints or designs with many gradients, high-resolution JPEG files (saved at maximum quality settings) work well. Vector files in AI, EPS, or PDF formats are ideal for logos, text, and graphics that need to scale to different sizes without quality loss. Resolution is critical—aim for at least 300 DPI (dots per inch) at the actual print size. Files at 150 DPI may be acceptable for larger prints, but lower resolutions will result in pixelated, blurry output. Color mode should be RGB rather than CMYK, as DTG printers use RGB color processing. File size isn’t a concern for quality—larger files with more information generally produce better prints than compressed or downsized versions. When preparing designs, remember that colors may appear slightly different on fabric than on screen due to substrate absorption and ink characteristics. Many professional DTG services offer color proofing or sample prints to verify the final appearance before full production runs.

How does DTG printing affect garment breathability?

One of DTG printing’s significant advantages is its minimal impact on fabric breathability compared to some other printing methods. The water-based inks penetrate into the fabric fibers rather than sitting on top as a thick layer, allowing air to pass through the printed areas more easily. On light-colored garments where white ink underbase isn’t required, the breathability impact is nearly imperceptible—the printed design feels integrated into the fabric rather than applied on top. Dark garments require white ink underbase and heavier ink coverage, which does create slightly more presence on the fabric surface and may reduce breathability in the printed area to some degree, though less so than thick vinyl transfers or heavy plastisol screen prints. The soft hand feel of DTG prints means the design moves naturally with the garment and doesn’t create the stiff, heavy sensation that can come from some printing methods. For activewear and garments where breathability is crucial, consider design placement and coverage area—smaller designs or those placed away from high-perspiration areas will maintain garment performance better than large, full-coverage prints. Overall, DTG printing represents one of the better options when breathability and comfort are priority considerations.

Summary Table: Key Insights About DTG Printing

| Aspect | Key Points | Considerations |

|---|---|---|

| Technology | Inkjet printing directly onto fabric using water-based inks; similar to paper printing but on textiles | Best on cotton and cotton blends; requires specialized equipment and maintenance |

| Design Capabilities | Unlimited colors, photorealistic detail, gradients, fine lines, and complex artwork | No color separation needed; maintains digital design integrity |

| Order Flexibility | No minimum quantities; cost-effective for 1-25 pieces; ideal for on-demand production | Per-unit cost higher than screen printing for large orders (100+ pieces) |

| Production Speed | Minimal setup time; fast turnaround for small orders; immediate production capability | Slower than screen printing for bulk orders; each piece printed individually |

| Print Quality | High resolution, vivid colors, soft hand feel; integrates into fabric fibers | Quality depends on proper pretreatment, curing, and fabric selection |

| Durability | 50+ wash cycles when properly produced and cared for; lasts the garment’s lifetime | Wash in cold water inside out; air dry preferred; avoid harsh detergents |

| Fabric Compatibility | Optimal on 100% cotton; good on cotton blends; developing polyester capabilities | Natural fibers preferred; pretreatment essential for dark garments |

| Environmental Impact | Water-based eco-friendly inks; on-demand production reduces waste; lower water consumption | More sustainable than traditional screen printing; eliminates overproduction waste |

| Cost Structure | Higher initial equipment investment; lower setup costs per design; variable ink costs | Most economical for small batches; cost advantage diminishes with volume |

| Applications | E-commerce, POD, custom merchandise, sampling, event apparel, wearable art, personalized gifts | Perfect for variety and customization; ideal for testing designs |

| Limitations | Higher per-unit cost at volume; slower for bulk orders; best on specific fabrics | Dark garments need extra steps; not ideal for 100+ identical pieces |

| Care Requirements | Cold water wash, inside out, gentle cycle, mild detergent, air dry or low heat | Proper care dramatically extends print life; avoid bleach and high heat |

| Market Growth | Strong consumer demand for personalization; expanding e-commerce opportunities | Rising consumer willingness to pay premium for customized products |

| Business Model Fit | Enables low-risk entry into apparel market; eliminates inventory costs; supports rapid testing | Ideal for start-ups, POD platforms, and brands prioritizing variety over volume |

DTG printing has fundamentally transformed the custom apparel landscape, making personalized t-shirt production accessible, affordable, and creatively limitless. As the technology continues to evolve and consumer demand for unique, personalized products grows, DTG printing’s role in the garment decoration industry will only expand. Whether you’re an entrepreneur launching a clothing brand, an artist seeking to share your work, or a business creating custom merchandise, understanding DTG printing’s capabilities and limitations empowers you to make informed decisions that bring your creative vision to life with exceptional quality and efficiency.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.