Cotton Canvas Fabric Weave Structure, Uses & Durability

Cotton canvas fabric has been a cornerstone of textile manufacturing for centuries, valued for its remarkable strength and versatility. From the historic sails of exploration vessels to contemporary fashion accessories and industrial applications, this heavy-duty fabric continues to prove its worth across countless industries. Understanding the weave structure, diverse applications, and durability characteristics of cotton canvas fabric enables designers, manufacturers, and consumers to make informed decisions for their specific needs.

Understanding Cotton Canvas Fabric

Cotton canvas fabric is a plain-woven textile made primarily from cotton fibers, characterized by its tight weave and substantial weight. According to Sewport, canvas is a heavy-duty fabric featuring thick yarn tightly woven in a simple plain-weave pattern. While historically made from hemp or linen, modern cotton canvas has become the preferred choice due to its availability, affordability, and excellent performance characteristics.

The term “canvas” originates from the Latin word “cannapaceus,” meaning made of hemp, reflecting the fabric’s ancient roots. Today, cotton canvas maintains the durability of its predecessors while offering improved softness and breathability. Through our work at Teebete, we’ve observed that customers increasingly seek cotton canvas for projects requiring both strength and comfort—a combination this versatile fabric delivers exceptionally well.

Types of Cotton Canvas

Several variations of cotton canvas fabric exist, each suited to different applications:

Plain Canvas features a single yarn in both the warp and weft directions, creating a straightforward, durable structure. This type typically has a thread count between 50 and 100, making it suitable for industrial purposes where maximum strength matters more than surface smoothness.

Duck Canvas represents a refined version with thinner threads and a closer weave. As explained by Canvas ETC, duck canvas is distinguished by its heavier weight and denser weave compared to standard plain-woven canvas. The numbered duck system classifies this fabric by weight, with numbers ranging from 1 (heaviest, around 30 oz/yd²) to 12 (lightest, around 11.5 oz/yd²).

Waxed Canvas undergoes treatment with beeswax, paraffin, or plant-based oils, creating water resistance while maintaining breathability. This variation has become popular for outdoor gear, bags, and jackets that need weather protection without sacrificing the natural characteristics of cotton.

The Plain Weave Structure Explained

The foundation of cotton canvas fabric lies in its plain weave structure—the simplest yet most fundamental of all textile weaves. Understanding this construction reveals why canvas performs so reliably across diverse applications.

How Plain Weave Works

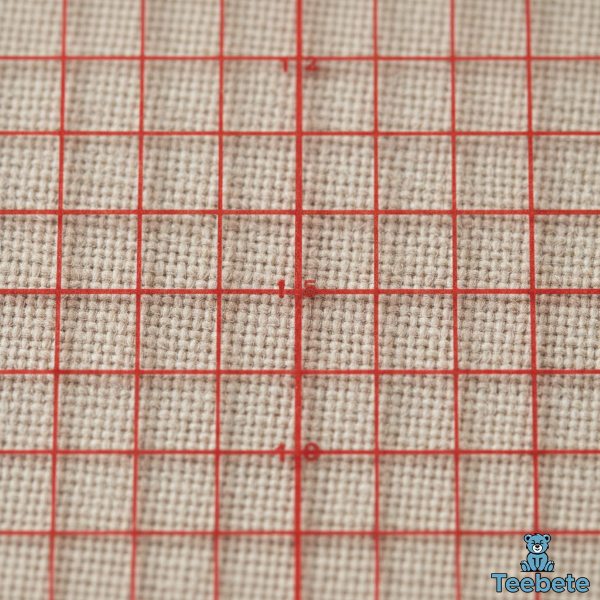

In a plain weave, warp threads (running lengthwise) and weft threads (running crosswise) intersect at right angles in a consistent pattern. According to Wikipedia, each weft thread crosses the warp threads by going over one, then under the next, creating a simple criss-cross pattern. This one-over-one-under sequence repeats throughout the entire fabric.

The plain weave structure offers several inherent advantages. The frequent intersections between warp and weft create exceptional fabric firmness and stability. Each thread supports its neighbors, distributing stress evenly across the material. This uniform structure results in a balanced fabric that resists distortion and maintains its shape under load.

From our experience working with customers at Teebete, we’ve found that many people underestimate the engineering elegance of plain weave. The simplicity masks sophisticated performance—every intersection point reinforces the fabric’s overall integrity, creating strength that exceeds the sum of its parts.

Thread Count and Fabric Characteristics

Thread count—the number of threads per inch in both directions—directly affects the properties of cotton canvas fabric. Canvas ETC notes that a higher thread count results in a denser, less permeable fabric, while a lower thread count creates a more open, breathable weave.

Canvas typically features relatively low thread counts compared to fine textiles. Most cotton canvas ranges from 50 to 150 threads per inch, depending on the intended use. This lower thread count doesn’t indicate weakness; rather, it reflects the use of thicker yarns that provide structural strength without requiring extremely tight weaving.

The trade-off between thread count and fabric weight creates interesting design possibilities. Lightweight canvas with a moderate thread count offers drape and flexibility, while heavyweight canvas with a tight weave delivers maximum durability for demanding applications.

Canvas Weight and GSM Ratings

Weight classification provides crucial information for selecting appropriate cotton canvas fabric for specific projects. Fabric weight is typically measured in ounces per square yard (oz/sq yd) or grams per square meter (GSM).

Weight Categories

Lightweight Canvas (4-7 oz/sq yd or 135-240 GSM) works well for linings, lightweight bags, aprons, and decorative applications. This weight offers easier handling and sewing while maintaining canvas characteristics.

Medium-Weight Canvas (8-10 oz/sq yd or 270-340 GSM) represents the most versatile category. This range provides an excellent balance of strength, flexibility, and workability. It’s ideal for tote bags, upholstery, medium-duty covers, and general crafting.

Heavyweight Canvas (12+ oz/sq yd or 410+ GSM) delivers maximum durability for tool bags, industrial equipment covers, heavy-duty upholstery, and outdoor gear that faces constant stress.

Based on what we’ve seen in our Teebete customer base, people often gravitate toward 10-12 oz cotton canvas fabric for general-purpose projects. This weight range handles most applications beautifully without requiring industrial sewing equipment or specialized needles.

Warp and Weft Thread Dynamics

The interaction between warp and weft threads defines canvas behavior and performance. Understanding this relationship helps explain why cotton canvas fabric excels in certain applications.

Thread Orientation and Strength

Warp threads run parallel along the length of the fabric and bear most of the tension during weaving. These threads typically receive slightly more twist, making them stronger and more resistant to breakage. Weft threads run perpendicular across the fabric width and interlace with warp threads to create the plain weave structure.

CottonWorks explains that in plain weave, one warp yarn weaves over one weft yarn and under the next one, with each adjacent end weaving opposite to create the characteristic checkerboard pattern visible under magnification.

This warp-weft interaction creates directional properties in the fabric. Canvas typically exhibits slightly different characteristics along the warp direction versus the weft direction. Understanding these directional differences matters when cutting patterns or positioning fabric for maximum strength.

Breathability and Natural Fiber Benefits

One significant advantage of cotton canvas fabric over synthetic alternatives is its natural breathability. The cotton fibers and plain weave structure allow air circulation, preventing heat and moisture buildup.

Why Breathability Matters

For apparel applications, breathability translates directly to comfort. Workers wearing canvas workwear appreciate the fabric’s ability to regulate temperature during physical activity. The natural moisture-wicking properties of cotton help keep wearers comfortable in varying conditions.

For bag applications, breathability prevents odor buildup and allows contents to remain fresh. Canvas tote bags don’t trap moisture the way non-breathable synthetic bags might, making them ideal for groceries, gym gear, and everyday carry items.

Here’s the part most people don’t realize: breathability also contributes to durability. Moisture trapped within fabric fibers can promote mildew growth and fiber degradation. The breathable nature of cotton canvas fabric helps prevent these issues, extending product lifespan when properly cared for.

Comprehensive Uses of Cotton Canvas Fabric

The versatility of cotton canvas fabric manifests in its extraordinary range of applications across multiple industries. Understanding these uses reveals why this fabric remains relevant centuries after its invention.

Fashion and Accessories

Cotton canvas has secured a permanent place in fashion, particularly for durable accessories. Tote bags represent perhaps the most recognizable application—canvas totes combine strength, style, and sustainability. The fabric easily handles heavy loads while accepting printing, dyeing, and embroidery for customization.

Backpacks, duffel bags, and messenger bags benefit from canvas’s abrasion resistance and structural integrity. According to ToteBagFactory, canvas is durable for making backpacks, tote bags, duffel bags, and messenger bags due to its toughness and longevity.

Canvas shoes have remained fashion staples for decades. The fabric provides breathability for comfortable all-day wear while withstanding the constant flexing and abrasion that footwear endures. Casual jackets, work wear, and outdoor apparel also utilize canvas for its protective qualities and classic aesthetic.

Home Décor and Upholstery

The home furnishing industry extensively employs cotton canvas fabric for both functional and aesthetic purposes. Upholstery applications take advantage of canvas’s ability to withstand repeated use without showing significant wear. Cushions, throw pillows, slipcovers, and furniture coverings showcase the fabric’s durability and design flexibility.

Canvas accepts various treatments and finishes, allowing manufacturers to create stain-resistant or water-repellent upholstery fabrics for high-traffic areas. The natural texture adds visual interest while maintaining a clean, contemporary appearance that complements diverse interior styles.

Curtains, tablecloths, and decorative wall hangings utilize lighter-weight canvas variations. These applications benefit from the fabric’s body—it hangs well without excessive limpness, creating pleasing drapes and folds. We’ve noticed a growing trend toward natural, sustainable home textiles, with cotton canvas perfectly positioned to meet this demand.

Industrial and Commercial Applications

Heavy-duty industrial uses continue to drive significant demand for cotton canvas fabric. Szoneier Fabrics notes that canvas is suitable for industrial and commercial applications because its tight weave, high GSM, and flexible finishes deliver long-term strength and moisture resistance.

Equipment covers, tarps, and protective sheeting rely on canvas’s tear resistance and weather protection. The fabric shields valuable equipment from dust, debris, and moisture without completely blocking air circulation, preventing condensation buildup.

Tool bags, utility pouches, and storage solutions benefit from canvas’s structural qualities. The fabric maintains its shape even when partially filled, providing organization and accessibility. Canvas doesn’t stretch or sag under weight, ensuring tools remain properly positioned and protected.

Commercial packaging increasingly favors cotton canvas for premium and sustainable branding. Canvas packaging bags project quality while supporting environmental initiatives. Retailers find that offering or selling branded canvas bags increases customer retention compared to disposable alternatives.

Artistic and Creative Applications

Artists have utilized canvas as a painting surface for centuries. Stretched canvas provides an ideal foundation for oils, acrylics, and mixed media work. The plain weave texture holds paint layers effectively while offering just enough give to prevent cracking.

According to Wikipedia, canvas has become the common support medium for oil painting, replacing wooden panels. The fabric’s lightweight nature compared to wood panels revolutionized art transportation and large-scale works.

Crafters and makers appreciate canvas for countless DIY projects. The fabric accepts screen printing, block printing, embroidery, and fabric paint beautifully. Its substantial weight makes it forgiving for beginners while offering enough refinement for advanced techniques.

Durability: How Long Does Cotton Canvas Last?

The question of durability interests anyone investing in cotton canvas products. Understanding the factors that affect lifespan helps set realistic expectations and guides proper care practices.

Expected Lifespan

Szoneier Fabrics reports that canvas fabric can last anywhere from 5 to 30 years depending on weight, fiber type, treatment, and exposure to UV, moisture, and abrasion. With proper care and maintenance, heavy-duty canvas used in bags, covers, and upholstery can exceed a decade of active use.

Several factors influence actual lifespan in real-world conditions:

Fabric Weight: Heavier canvas naturally withstands more abuse than lighter versions. A 16 oz bag will outlast an 8 oz bag in identical conditions, sometimes by several years.

Usage Intensity: Daily-use items experience more stress than occasionally-used products. A canvas tote carried daily will show wear faster than one used weekly, regardless of construction quality.

Environmental Exposure: UV radiation, moisture, and temperature fluctuations accelerate fabric degradation. Outdoor applications face harsher conditions than indoor uses.

Care and Maintenance: Proper cleaning, storage, and occasional reproofing treatments significantly extend canvas lifespan. Neglected canvas degrades faster than well-maintained fabric.

In our experience at Teebete, customers who follow care instructions and match fabric weight to intended use consistently report satisfaction with canvas longevity. The key isn’t just the fabric itself—it’s understanding how to select and maintain it properly.

Factors Affecting Canvas Fabric Durability

Abrasion Resistance: Cotton canvas excels in abrasion resistance testing. The tight weave and substantial fibers resist surface wear from rubbing and friction. This characteristic makes canvas ideal for applications involving repeated contact or movement.

Tear Strength: The plain weave structure distributes stress effectively, making canvas difficult to tear. If a tear does start, the weave pattern helps prevent propagation—damaged threads remain anchored by surrounding intersections.

UV Degradation: Untreated cotton canvas shows moderate UV resistance. Extended sun exposure gradually weakens fibers through photodegradation. For outdoor applications, UV-protective treatments or synthetic blends offer enhanced resistance.

Moisture Resistance: Natural cotton canvas absorbs moisture, which can lead to mildew in damp conditions. Treatments like waxing, PU coating, or silicone application create water resistance while maintaining many of canvas’s desirable properties.

Dimensional Stability: Cotton canvas can shrink when washed, typically 3-8% for untreated fabric. Preshrunk or sanforized canvas addresses this issue, maintaining dimensions through wash cycles. Understanding shrinkage matters for projects requiring precise sizing.

Canvas Fabric Construction Methods

The manufacturing process significantly impacts the final properties of cotton canvas fabric. Understanding construction methods helps explain performance variations between products.

Fiber Selection and Yarn Preparation

Cotton canvas begins with fiber selection. Long-staple cotton produces stronger, smoother yarns than short-staple varieties. According to Sewport, canvas incorporates unusually thick yarn that doesn’t require significant softness, so manufacturers commonly use rougher fibrous parts of cotton plants.

Yarn undergoes carding rather than combing for most canvas applications. Carding aligns fibers sufficiently for spinning without the additional refinement combing provides. This process suits canvas perfectly—the fabric prioritizes strength over silkiness.

Yarn twist affects fabric properties. More tightly twisted yarns create firmer, more durable fabrics. Plied yarns (two or more singles twisted together) further enhance strength, particularly in numbered duck canvas where multiple plied yarns weave together.

Weaving and Finishing

The weaving process establishes canvas’s fundamental structure. Modern mechanical looms efficiently produce consistent plain weave fabrics in various widths and weights. Tension control during weaving affects fabric hand and performance—proper tension creates even, stable canvas.

Finishing treatments transform raw canvas into application-specific materials:

Bleaching lightens natural cotton’s ecru color to pure white, providing a neutral base for dyeing or printing.

Dyeing adds color through various methods. Piece dyeing treats entire fabric lengths, while yarn dyeing colors individual yarns before weaving.

Sizing applies starch or synthetic compounds to stiffen fabric temporarily, improving handling during garment construction. Sizing typically washes out during initial laundering.

Coating applications include PVC for waterproofing, acrylic for weather resistance, and fire-retardant chemicals for safety applications. Each treatment modifies performance while changing fabric characteristics.

Preshrinking processes like sanforization compress fabric to prevent excessive shrinkage during consumer use, ensuring dimensional stability.

Difference Between Duck Canvas and Regular Canvas

The terms “canvas” and “duck canvas” often create confusion. While related, these designations indicate specific structural and performance differences.

Structural Distinctions

Regular plain canvas uses single yarns in both warp and weft directions. The weave remains simple and straightforward, creating a moderately dense fabric suitable for general purposes.

Duck canvas, by contrast, typically employs plied yarns—two or more singles twisted together before weaving. According to Fabric Wholesale Direct, number duck canvas fabric is woven with two or more plied yarns in both warp and weft, making the canvas thicker, denser, smoother, and sturdier.

This structural difference creates noticeable performance variations. Duck canvas feels smoother and more refined than plain canvas of similar weight. The increased yarn thickness and tighter weave produce superior abrasion resistance and tear strength.

Practical Implications

For projects requiring maximum durability, duck canvas typically outperforms standard canvas. The denser construction better resists wear, moisture penetration, and structural degradation. Tool bags, heavy-duty upholstery, and industrial equipment covers benefit from these enhanced properties.

For applications prioritizing flexibility, breathability, or cost-effectiveness, standard canvas often suffices. Art canvases, lightweight bags, and decorative items work beautifully with plain canvas without requiring duck canvas’s premium characteristics.

Price differences reflect construction complexity. Duck canvas commands higher prices due to additional yarn processing and tighter weaving requirements. Understanding these differences helps buyers balance performance needs against budget constraints.

Choosing the Right Cotton Canvas Weight

Selecting appropriate fabric weight represents perhaps the most crucial decision when specifying cotton canvas for a project. This is where things get tricky—the “best” weight depends entirely on intended use, and the range of options can overwhelm newcomers.

Weight Selection Guidelines

4-7 oz Canvas: Choose this range for projects requiring drape and flexibility. Applications include linings, light tote bags, aprons, simple crafts, and decorative items. The fabric remains easy to sew on standard home machines without specialized needles or thread.

8-10 oz Canvas: This versatile middle ground handles most general applications beautifully. Medium tote bags, cushion covers, light upholstery, banners, and bags benefit from this weight’s balance between durability and workability. It’s the sweet spot for makers and small manufacturers.

12-15 oz Canvas: Heavy-duty applications come into their own at this weight. Tool bags, work wear, heavy upholstery, equipment covers, and outdoor gear utilize this range. Sewing requires heavy-duty machines, size 16-18 needles, and strong thread.

16+ oz Canvas: Industrial and extreme-duty applications demand this heavyweight construction. Military gear, heavy equipment covers, and specialized outdoor products utilize these weights. Processing requires industrial equipment and expertise.

We consistently recommend 10-12 oz cotton canvas fabric for customers uncertain about requirements. This range provides excellent performance across diverse applications while remaining accessible to makers with standard equipment.

Advantages of Cotton Canvas Over Synthetic Fabrics

While synthetic alternatives offer certain benefits, cotton canvas fabric provides distinct advantages that continue attracting users across industries.

Natural and Sustainable

Cotton canvas comes from renewable cotton plants, making it biodegradable at end-of-life. Unlike petroleum-based synthetics, cotton production utilizes sustainable agricultural practices when responsibly sourced. Many manufacturers now offer organic cotton canvas, further reducing environmental impact.

The natural composition means cotton canvas doesn’t contribute microplastic pollution. Synthetic fabrics shed microscopic plastic fibers during washing and wear, accumulating in waterways and ecosystems. Canvas avoids this environmental concern entirely.

Comfort and Breathability

The breathable nature of cotton canvas provides comfort that synthetics struggle to match. Air circulation prevents heat buildup during wear, particularly important for apparel and bags. Natural fibers also wick moisture more effectively than most synthetic alternatives.

Hypoallergenic properties make cotton canvas suitable for sensitive individuals. The fabric doesn’t trap irritants the way some synthetics might, and it lacks the chemical treatments often applied to synthetic materials.

Aesthetic Appeal

Cotton canvas offers a natural, authentic appearance that resonates with consumers seeking quality craftsmanship. The texture, drape, and aging characteristics create visual appeal that synthetic substitutes often fail to replicate convincingly.

Canvas develops an appealing patina over time, particularly waxed varieties. The fabric softens with use while maintaining structural integrity, creating products that improve with age rather than simply wearing out.

Disadvantages and Limitations of Cotton Canvas

Understanding cotton canvas fabric requires acknowledging its limitations alongside its strengths. No material performs perfectly in all situations, and canvas has specific drawbacks to consider.

Weight and Stiffness

According to Szoneier Fabrics, canvas, particularly tightly woven types like duck canvas, has near-zero elasticity. The stiff, heavy nature that provides durability also creates challenges for certain applications.

Products requiring drape, stretch, or compact folding work poorly in canvas. The fabric resists manipulation, making it unsuitable for form-fitting garments or applications needing significant flexibility. Foldable or compressible products struggle with stiff canvas.

Heavy canvas can cause discomfort in children’s products or items requiring extended carrying. An 18 oz canvas bag might be wonderfully durable but painfully heavy when loaded with groceries or books.

Shrinkage and Dimensional Changes

Untreated cotton canvas shrinks significantly when washed—typically 8-12% according to various sources. This characteristic creates challenges for projects requiring precise dimensions. A carefully constructed bag or cover might become too tight after the first wash without preshrinking.

Preshrunk or sanforized canvas addresses this issue but adds cost. Buyers must verify whether fabric has undergone preshrinking treatment or account for shrinkage in their patterns and specifications.

Water Absorption

Natural cotton canvas absorbs water readily unless treated. Moisture absorption leads to several problems:

- Mildew Growth: Damp canvas left unaired develops mold and mildew, causing odors and fabric degradation.

- Staining: Water-based stains penetrate untreated canvas easily, often proving difficult to remove completely.

- Weight Increase: Wet canvas becomes significantly heavier, an important consideration for outdoor gear.

Waxing, coating, or other treatments provide water resistance but alter fabric characteristics. Treated canvas loses some breathability and natural feel while gaining weather protection.

Maintenance Requirements

Canvas requires more care than many synthetic alternatives. Regular cleaning prevents buildup that accelerates wear. Spot cleaning addresses stains before they set. Periodic reproofing maintains water resistance in treated canvas.

Storage matters too. Canvas stored in damp, poorly ventilated conditions deteriorates faster than fabric kept dry and aired. Folding creates permanent creases in stiff canvas, while rolling preserves shape better for long-term storage.

In reality, most people overlook these maintenance requirements until problems appear. A little preventive care dramatically extends canvas lifespan, but busy lives often postpone maintenance until damage occurs.

Proper Care and Maintenance

Maximizing the lifespan and performance of cotton canvas fabric requires appropriate care practices. Understanding proper maintenance techniques protects investments and ensures continued functionality.

Cleaning Cotton Canvas

Regular Maintenance: Brush off dry dirt and debris promptly using a soft brush. This simple practice prevents abrasive particles from grinding into fibers during use. For bags and accessories, emptying and shaking out contents regularly removes accumulated debris.

Spot Cleaning: Address stains immediately using mild soap and cold water. Blot rather than rubbing to avoid spreading stains or damaging fibers. For stubborn stains, let the soap solution sit briefly before blotting.

Machine Washing: When machine washing becomes necessary, use cold or warm water with mild detergent. Hot water accelerates shrinkage and color fading. Select gentle cycles to minimize mechanical stress on fibers and seams. Avoid bleach unless specifically required and fabric-appropriate.

Hand Washing: For delicate items or treated canvas, hand washing provides gentler cleaning. Submerge canvas in cool water with mild detergent, gently agitate, and rinse thoroughly. Never wring or twist canvas—squeeze gently and roll in towels to remove excess water.

Drying: Air drying preserves canvas best. Hang items in well-ventilated areas away from direct sunlight to prevent UV damage and fading. If tumble drying, use low heat settings and remove items while slightly damp to prevent over-drying and shrinkage.

Treating and Protecting Canvas

Waterproofing: Apply waterproofing treatments periodically to maintain water resistance. Wax-based treatments suit traditional canvas, while spray-on products work well for synthetic blends. Reapply after washing or when water no longer beads on the surface.

UV Protection: For outdoor applications, UV-protective sprays help slow photodegradation. Reapply seasonally or according to product instructions to maintain effectiveness.

Storage: Store clean, completely dry canvas in cool, dry locations. Avoid plastic bags that trap moisture—breathable cotton bags or acid-free tissue provide better protection. For long-term storage, add silica gel packets to absorb residual moisture.

Environmental Considerations

The environmental profile of cotton canvas fabric encompasses both advantages and concerns. Understanding these factors helps consumers and manufacturers make responsible choices.

Sustainable Aspects

Cotton canvas’s biodegradability represents a significant environmental advantage over synthetic alternatives. At end-of-life, cotton fabric decomposes naturally without leaving persistent pollutants. This characteristic aligns with circular economy principles and reduces long-term waste accumulation.

The durability of canvas extends product lifecycles, reducing replacement frequency and associated resource consumption. A canvas bag lasting ten years prevents dozens of disposable alternatives from entering waste streams.

Environmental Challenges

Cotton cultivation requires substantial water resources and often involves pesticide use. Conventional cotton farming contributes to water pollution and soil degradation when poorly managed. These impacts offset some of canvas’s end-of-life advantages.

Organic cotton production addresses these concerns through sustainable farming practices. Organic certification prohibits synthetic pesticides and promotes soil health, significantly reducing environmental footprint. While organic canvas costs more, the premium supports more responsible production.

Processing and finishing treatments add environmental considerations. Bleaching, dyeing, and coating processes consume energy and may generate pollutants depending on methods used. Eco-conscious manufacturers increasingly adopt closed-loop systems and low-impact treatments.

Best Practices for Cotton Canvas Projects

Successfully working with cotton canvas fabric requires understanding best practices that ensure quality results and optimal performance.

Sewing Considerations

Needles: Use heavy-duty needles (size 90/14 to 110/18) depending on fabric weight. Denim or canvas-specific needles resist bending and breakage better than universal needles. Change needles regularly—dull needles cause skipped stitches and fabric damage.

Thread: Select strong polyester or cotton-wrapped polyester thread matching fabric weight. Thread that’s too light breaks under tension; thread that’s too heavy creates bulk and puckering. For visible topstitching, consider decorative threads that complement canvas texture.

Stitch Length: Use longer stitch lengths (8-10 stitches per inch) for canvas to prevent excessive perforation that weakens seams. Test stitching on scraps to determine optimal settings before starting projects.

Pressing: Press seams and hems with high heat and steam. Canvas requires more heat than lightweight fabrics to create crisp folds and flat seams. Use a pressing cloth to prevent shine on fabric face.

Design Recommendations

Pattern Selection: Choose patterns designed for heavyweight fabrics. Designs requiring gathering, pleating, or significant draping work poorly in stiff canvas. Simple, structured patterns showcase canvas’s natural characteristics best.

Seam Allowances: Increase seam allowances to 5/8″ or 3/4″ for heavyweight canvas. The extra fabric provides strength at stress points and accommodates multiple seam layers at intersections.

Reinforcement: Double-stitch stress points like bag handles, pocket attachments, and zipper ends. Consider adding reinforcement patches at high-stress areas using lighter-weight canvas or interfacing.

Pre-washing: Always pre-wash fabric before cutting unless using preshrunk canvas. This step prevents size distortion in finished projects and removes residual sizing that might affect dye or paint acceptance.

Industry Applications and Case Studies

Real-world applications demonstrate cotton canvas fabric’s versatility and performance across diverse industries. These examples illustrate practical considerations and solutions.

Fashion and Retail

Premium brands increasingly incorporate canvas into accessory lines, emphasizing sustainability and durability. Canvas tote bags have evolved from utilitarian grocery carriers to fashion statements, with designers showcasing printed graphics, embroidery, and premium hardware.

One successful strategy involves offering canvas bags as premium alternatives to disposable packaging. Customers perceive canvas bags as valuable items worth keeping and reusing, effectively turning packaging into long-term brand advertising.

Outdoor and Recreation

Camping equipment manufacturers rely on cotton canvas for tents, gear bags, and outdoor furniture. The fabric’s breathability prevents condensation buildup that plagues synthetic tents, while its durability withstands repeated setup and breakdown.

Modern outdoor brands often combine treated canvas with synthetic components, creating hybrid products that maximize each material’s strengths. Canvas bodies provide breathability and durability while synthetic floors and rainflies offer waterproof protection.

Commercial and Industrial

Facilities managers appreciate canvas equipment covers for protecting machinery and materials. The fabric shields against dust and debris while allowing air circulation that prevents rust and corrosion—a balance waterproof synthetics cannot achieve.

Tool manufacturers specify duck canvas for tool bags and storage solutions. The structured nature keeps tools organized and accessible while the abrasion resistance protects against the constant wear that metal tools inflict.

Frequently Asked Questions

What is cotton canvas fabric used for?

Cotton canvas fabric serves countless applications across multiple industries. Common uses include bags (tote bags, backpacks, duffel bags), footwear (sneakers, casual shoes), apparel (jackets, work wear, aprons), home décor (upholstery, cushions, curtains, slipcovers), outdoor gear (tents, covers, tarps), art supplies (painting canvases), and industrial equipment (covers, tool bags, protective sheeting). The fabric’s combination of strength, durability, and versatility makes it suitable for both decorative and functional purposes. According to Mood Fabrics, canvas is the go-to fabric for crafting durable and stylish accessories, functional outdoor gear, and elegant home décor projects.

What is the weave structure of canvas fabric?

Canvas fabric utilizes a plain weave structure, the simplest of all textile weaves. In plain weave, warp threads (running lengthwise) and weft threads (running crosswise) interlace in an alternating over-under pattern. Each weft thread passes over one warp thread, then under the next, creating a checkerboard-like pattern when viewed closely. This simple yet effective structure creates exceptional strength and stability because threads intersect at right angles throughout the fabric. Canvas ETC explains that the plain weave’s stable structure contributes to canvas’s durability and even surface texture. The frequency of intersections ensures excellent firmness and prevents the fabric from distorting under stress.

How long will cotton canvas last?

The lifespan of cotton canvas depends on several factors including fabric weight, usage intensity, environmental exposure, and maintenance practices. Generally, cotton canvas can last anywhere from 5 to 30 years. Lightweight canvas (4-7 oz) in daily-use applications might last 5-7 years, while heavy-duty canvas (12+ oz) with proper care can exceed 15-20 years. Bags and upholstery items typically last 10-15 years with regular use. Outdoor applications face harsher conditions—untreated canvas exposed to weather might degrade within 3-5 years, while treated canvas with proper maintenance can last 10-15 years outdoors. Szoneier Fabrics notes that with proper care and maintenance, heavy-duty canvas used in bags, covers, and upholstery can exceed a decade of active use. The key factors affecting longevity include choosing appropriate weight for intended use, protecting against UV exposure and moisture, and following recommended care practices.

What are the disadvantages of cotton canvas?

Cotton canvas has several notable disadvantages despite its many strengths. Weight and stiffness present the most obvious drawback—canvas lacks flexibility and drape, making it unsuitable for applications requiring stretch or form-fitting properties. The fabric can be uncomfortably heavy for extended carrying or children’s products. Shrinkage poses another challenge; untreated cotton canvas typically shrinks 8-12% when washed, requiring preshrinking treatment or pattern adjustments. Water absorption leads to multiple issues including mildew growth in damp conditions, staining from water-based substances, and significant weight increase when wet. According to Szoneier Fabrics, untreated or loosely woven canvas fabrics are most susceptible to damage from friction, water, and punctures. Canvas also requires more maintenance than synthetic alternatives, needing regular cleaning, proper storage, and periodic waterproofing treatments to maintain performance. Additionally, canvas tends to fray at cut edges, requiring proper finishing techniques for clean, professional results.

Is cotton canvas good for outdoor use?

Cotton canvas can be excellent for outdoor use when properly treated and maintained, though it has limitations. Untreated cotton canvas absorbs moisture readily, leading to mildew, staining, and fabric degradation when exposed to weather. However, treated cotton canvas—waxed, coated, or chemically protected—provides good weather resistance while maintaining breathability. The fabric’s UV resistance is moderate; extended sun exposure gradually weakens fibers without protective treatments. Canvas excels in applications like tents, awnings, and outdoor furniture covers where breathability matters, preventing condensation buildup that damages synthetic materials. For optimal outdoor performance, choose heavyweight canvas (12+ oz), apply or verify protective treatments, provide proper drainage and ventilation, bring items indoors during harsh weather when possible, and clean and dry thoroughly after exposure to moisture.

How do you choose between duck canvas and regular canvas?

Choosing between duck canvas and regular canvas depends on your specific project requirements and budget. Duck canvas features plied yarns creating a denser, smoother, and stronger fabric compared to regular canvas which uses single yarns. Select duck canvas for applications demanding maximum durability such as heavy-duty tool bags, work wear, industrial covers, high-traffic upholstery, and outdoor gear exposed to harsh conditions. Choose regular canvas for projects prioritizing affordability like art canvases, lightweight tote bags, crafts and DIY projects, decorative home items, and applications where extreme durability isn’t critical. Duck canvas costs more due to additional yarn processing and tighter weaving but delivers superior abrasion resistance, tear strength, and longevity. Regular canvas offers excellent performance for moderate-use applications at a more accessible price point. Consider weight alongside weave structure—a heavyweight regular canvas might outperform lightweight duck canvas in certain applications.

Can you print on cotton canvas fabric?

Yes, cotton canvas fabric accepts various printing methods exceptionally well, making it popular for custom designs and artwork. Screen printing produces vibrant, durable designs ideal for tote bags, banners, and apparel. This method works particularly well on medium to heavyweight canvas (8-12 oz). Digital printing provides photographic quality and complex color gradations, perfect for art reproductions and detailed graphics. Heat transfer printing allows customization in small batches, though durability may be less than screen printing. Block printing creates artisanal, handcrafted appearances. Before printing, ensure canvas has been properly prepared—primed or treated canvas accepts ink more evenly than raw fabric. Medium-weight canvas (8-10 oz) generally provides the best balance for printing projects, offering sufficient stability without requiring industrial equipment. We’ve seen stunning custom canvas projects ranging from personalized tote bags to gallery-quality art prints, all leveraging canvas’s receptivity to various printing techniques.

Does cotton canvas stretch or shrink?

Cotton canvas exhibits minimal stretch but significant shrinkage potential. The plain weave structure and tight yarn construction prevent the fabric from stretching during use—canvas maintains its dimensions under normal stress, which contributes to its structural integrity. This lack of elasticity makes canvas unsuitable for applications requiring flexibility or form-fitting properties. However, untreated cotton canvas shrinks considerably when washed, typically 8-12% according to industry standards. This shrinkage occurs in both length and width as cotton fibers relax and contract when exposed to water and heat. To manage shrinkage, purchase preshrunk or sanforized canvas that has undergone industrial shrinking processes, always prewash fabric before cutting patterns if using untreated canvas, account for potential shrinkage in pattern calculations if prewashing isn’t possible, and wash finished items in cold water and air dry to minimize additional shrinkage. The first wash produces the most dramatic shrinkage; subsequent washing causes minimal additional size change.

Summary Table: Cotton Canvas Fabric Key Information

| Aspect | Key Details |

|---|---|

| Weave Structure | Plain weave with warp and weft threads intersecting in one-over-one-under pattern; creates exceptional strength and stability |

| Fabric Weight Range | Lightweight (4-7 oz), Medium (8-10 oz), Heavyweight (12-15 oz), Industrial (16+ oz) |

| Primary Uses | Bags, upholstery, outdoor gear, footwear, work wear, art canvases, industrial covers, home décor |

| Durability Lifespan | 5-30 years depending on weight, treatment, usage, and maintenance; heavy-duty canvas can exceed 15 years with proper care |

| Main Advantages | Exceptional durability, breathability, natural composition, biodegradable, accepts various treatments, develops attractive patina |

| Key Limitations | Weight and stiffness, shrinkage (8-12% untreated), water absorption, requires maintenance, lacks elasticity |

| Duck Canvas Distinction | Uses plied yarns for denser, smoother, stronger fabric compared to single-yarn regular canvas |

| Care Requirements | Cold/warm water washing, air dry preferred, avoid bleach, spot clean stains promptly, reproof water resistance periodically |

| Environmental Profile | Biodegradable and renewable but requires significant water/pesticides in cultivation; organic options available |

| Best Weight for General Use | 10-12 oz provides excellent balance of strength, workability, and versatility for most projects |

Conclusion

Cotton canvas fabric represents one of textile manufacturing’s most enduring success stories. From ancient sailing vessels to contemporary fashion accessories, this remarkable material continues proving its worth through exceptional durability, versatility, and performance. Understanding canvas weave structure, proper weight selection, and appropriate care practices enables designers, manufacturers, and consumers to maximize the fabric’s considerable benefits.

The plain weave structure underlying all canvas provides the foundation for its legendary strength. Warp and weft threads intersecting at right angles create a stable, balanced textile that distributes stress evenly and resists tearing and abrasion. Whether choosing lightweight canvas for artistic applications or heavyweight duck canvas for industrial demands, the fundamental weave structure delivers reliable performance.

Here at Teebete, we’ve witnessed cotton canvas fabric’s remarkable ability to meet diverse needs across industries and applications. The fabric’s natural composition aligns with growing sustainability demands while its proven durability reduces waste through extended product lifecycles. Though synthetic alternatives offer certain advantages, canvas’s combination of breathability, strength, and authentic character maintains its position as a preferred material for quality-conscious manufacturers and consumers.

Proper selection and care transform cotton canvas from simply durable material into long-lasting, high-performing products that improve with use. By matching fabric weight to intended application, following appropriate maintenance practices, and understanding canvas’s limitations alongside its strengths, users can achieve exceptional results that justify canvas’s centuries-long reputation for excellence. Whether crafting a simple tote bag or specifying fabric for industrial equipment covers, cotton canvas fabric delivers time-tested performance that continues earning trust across generations.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.