What Is Cotton Duck Fabric? The Ultimate Canvas Material Guide

When it comes to durable textiles that can withstand heavy use while maintaining their integrity, cotton duck fabric stands out as one of the most reliable choices available. This versatile canvas material has served countless applications for centuries, from maritime sails to modern workwear, and continues to be a go-to option for projects demanding both strength and functionality.

Understanding What Cotton Duck Canvas Is

Cotton duck fabric is a heavyweight, tightly woven cotton textile known for its exceptional durability and strength. The term “duck” actually derives from the Dutch word “doek,” meaning cloth, and has nothing to do with waterfowl. This plain-weave fabric features a distinctive construction where two yarns are woven together in the warp direction while a single yarn runs through the weft, creating a remarkably dense and robust canvas material.

What is duck canvas fabric made of exactly? Unlike some modern canvas variations that incorporate synthetic fibers, traditional cotton duck canvas is crafted from 100% natural cotton fibers. The cotton plant provides the raw material, which is then processed and woven using specific techniques that maximize the fabric’s strength. This natural composition makes duck canvas breathable while still offering impressive resistance to wear and tear.

The defining characteristic of what is cotton duck canvas lies in its tight plain weave structure. According to textile industry standards, duck canvas is more tightly woven than regular canvas, which directly contributes to its superior durability and smooth surface texture. This construction method has remained largely unchanged for generations because it simply works.

The Classification System of Duck Fabric

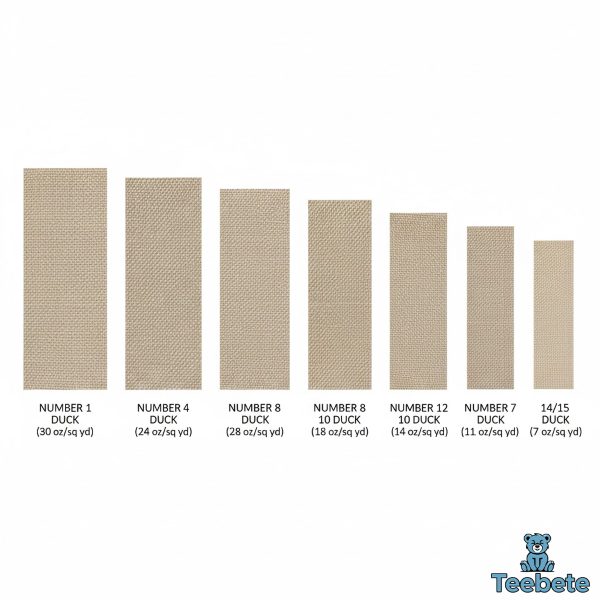

Understanding cotton duck fabric requires familiarity with its unique numbering system. Duck cloth fabric is classified according to weight using a numerical grading system established by the United States Department of Commerce in the 1920s. This standardized approach helps manufacturers and consumers alike select the appropriate canvas fabric for their specific needs.

The numbered duck classification system operates on an inverse scale where lower numbers indicate heavier, more robust fabrics. Number 1 duck canvas is the heaviest option, weighing approximately 30 ounces per square yard, while Number 12 represents the lightest numbered variety at around 11.5 ounces per square yard. The formula for this system is: Number of Duck = 19 − (Weight per linear yard 22 inches wide in ounces).

Here’s where things get interesting: there are actually two main categories of cotton duck canvas material. Single-fill duck fabric is typically lighter weight, measured in ounces per square yard (like 7oz, 10oz, or 12oz), and uses non-plied single yarns woven in an oxford-style pattern. This makes it softer and more pliable compared to numbered ducks.

Numbered ducks, conversely, utilize plied yarns—two single yarns twisted together—which creates a heavier, stiffer fabric ranging from 12 to 32 ounces per square yard. These heavy duty canvas options are purpose-built for applications requiring maximum strength and abrasion resistance.

Popular Weight Classifications for Canvas Material by the Yard

When shopping for duck canvas by the yard, you’ll encounter several common weights:

Lightweight Options (7-10oz): Perfect for bag linings, lightweight apparel, banners, and artist canvas applications. These weights are particularly popular among crafters working on tote bags and decorative projects where drape and ease of sewing matter more than extreme durability.

Medium-Weight Canvas (10-12oz): This versatile range balances strength with workability. Cotton canvas fabric by the yard in these weights works beautifully for upholstery, slipcovers, sturdy bags, aprons, and medium-duty outdoor applications. From experience in the apparel industry, 10oz canvas material hits a sweet spot—it’s substantial enough for furniture projects but still manageable on most home sewing machines.

Heavyweight Duck (15-24oz): These are the workhorses. Number 10, Number 8, Number 6, and Number 4 duck cloth fabric excel in demanding environments. Think industrial covers, heavy-duty tarps, work clothes, equipment bags, and tent construction. Canvas cloth in these weights can take serious punishment without showing wear.

Ultra-Heavy Applications (24-30oz): The heaviest cotton duck fabric options are reserved for the most extreme conditions—sandbags, floor coverings, conveyor belting, military equipment, and industrial applications where failure simply isn’t an option.

Key Properties of Duck Canvas Fabric

What makes duck canvas fabric such an enduring choice across industries? The answer lies in its impressive array of properties.

Durability and Abrasion Resistance: The tightly woven structure creates a smooth surface that resists snagging and tearing. Cotton duck canvas demonstrates remarkable resistance to rough wear, making it ideal for work environments and outdoor gear. The fabric literally gets better with age—it develops a pleasant patina while maintaining its structural integrity.

Breathability: Despite its density, cotton duck canvas breathes thanks to its natural cotton composition. Air can circulate through the weave, which is particularly beneficial for apparel and items used in warm conditions. This property distinguishes cotton canvas from synthetic alternatives that trap heat and moisture.

Natural Water Resistance: The tight weave provides inherent resistance to moisture penetration. While not waterproof in its natural state, duck fabric repels light rain and splashes effectively. For enhanced protection, the canvas material can be treated with wax or specialized coatings to achieve full waterproofing.

Strength and Stability: Duck cloth fabric maintains its shape exceptionally well. The plied yarn construction in numbered ducks creates a stable textile that won’t stretch or distort easily, even under stress. This stability makes it perfect for applications requiring dimensional accuracy.

Break-in Character: Initially, heavy duty canvas can feel quite stiff. However, this is where things get tricky—people often mistake initial stiffness for permanent discomfort. In reality, most people overlook how quickly quality cotton duck fabric softens with use and washing, transforming into a comfortable material that conforms to its purpose while retaining strength.

Natural Aesthetic: The cotton duck canvas material offers an authentic, rustic appearance that many designers and craftspeople value. Whether in natural off-white, dyed colors, or treated finishes, it brings a timeless quality to any project.

Extensive Applications of Canvas Fabric

The versatility of cotton duck fabric manifests in an remarkable range of applications across multiple industries.

Workwear and Apparel

Heavy-duty canvas has been the fabric of choice for work clothing for generations. Pants, jackets, overalls, and aprons made from duck fabric withstand the rigors of construction sites, workshops, and industrial environments. The fabric’s ability to resist abrasion while blocking wind makes it invaluable for outdoor labor.

What is duck cloth fabric used for in fashion? Beyond purely utilitarian purposes, cotton canvas fabric has found its way into mainstream fashion. Durable jackets, casual pants, and footwear all benefit from duck canvas’s combination of toughness and comfort. The fabric softens beautifully with wear, developing character unique to each garment.

Bags and Accessories

From Teebete’s perspective, one of the most satisfying applications of cotton duck fabric is in bag construction. Tote bags, backpacks, duffel bags, messenger bags, and gear bags made from canvas material deliver exceptional longevity. The fabric holds its shape beautifully, handles heavy loads without stretching, and develops an attractive worn-in look over time.

Here’s the part most people don’t realize: lighter weight cotton canvas fabric by the yard (7-10oz) often performs just as well for everyday bags as heavier weights, with the added benefit of being easier to sew and more comfortable to carry. You don’t always need the heaviest option.

Home Furnishings and Décor

Duck canvas material excels in residential applications. Slipcovers protect furniture while adding a clean, casual aesthetic. Upholstery fabric made from canvas cloth stands up to daily wear far better than delicate textiles. Curtains, pillow covers, tablecloths, and cushions all benefit from the fabric’s durability and natural appearance.

Canvas material by the yard is particularly economical for large home projects. Wide widths up to 144 inches minimize seaming in window treatments and bedding applications.

Outdoor and Marine Uses

The historical connection between duck fabric and maritime applications remains relevant today. Boat covers, awnings, tarps, and tent canvas must withstand sun, wind, rain, and salt spray—conditions where cotton duck canvas truly shines. When properly treated, the fabric becomes weather-resistant while maintaining breathability, preventing mildew-promoting condensation.

Art and Creativity

Artists have relied on duck cloth fabric for centuries. What is canvas material made of in art supplies? Typically, it’s cotton duck canvas—specifically lighter weights like Number 10 or Number 12, which provide an excellent surface for oil and acrylic paints. The tight, even weave accepts primers smoothly and holds paint without excessive absorption.

From experience in the apparel industry, many beginning artists don’t realize they can purchase raw cotton duck fabric by the yard and prepare their own canvases at a fraction of the cost of pre-stretched alternatives.

Industrial and Commercial Applications

Heavy cotton duck fabric serves critical roles in manufacturing and industry. Conveyor belts utilize belting duck for its strength. Drop cloths protect surfaces during painting and construction. Equipment covers shield machinery from dust and weather. Sandbags for flood control, director’s chairs, hammocks, and countless specialized applications all rely on the dependable performance of duck canvas material.

Specialized Types of Duck Canvas

Beyond the basic numbered and single-fill classifications, several specialized varieties of cotton duck fabric serve specific purposes.

Army Duck Canvas: This medium-weight option features a particularly tight weave with fine, plied yarns. Originally developed for military tents and uniforms, army duck balances weight with exceptional strength. It’s firmer than single-fill canvas cloth but lighter than the heaviest numbered ducks, making it versatile for both commercial and recreational applications.

Belting Duck: Purpose-engineered for conveyor systems, belting duck emphasizes fill yarn strength. This extra-heavy construction handles extreme tension and abrasion in industrial settings.

Waxed Canvas: Cotton duck fabric treated with paraffin or beeswax develops superior water resistance while maintaining breathability. Waxed canvas cloth ages beautifully, developing a distinctive patina that many users prize. However, the wax treatment requires periodic reapplication to maintain effectiveness.

Fire-Retardant Canvas: For applications where flame resistance is critical—such as event tents, industrial curtains, and protective coverings—cotton duck canvas can be treated with fire-retardant chemicals. These treatments meet various safety standards while preserving the fabric’s basic properties.

Understanding Canvas Breathability

Is cotton duck canvas breathable? This question frequently arises, particularly for apparel and tent applications. The answer is a definite yes—cotton duck canvas maintains good breathability despite its dense weave.

Cotton, as a natural fiber, allows air circulation through its structure. Even in heavy weight duck cloth fabric, microscopic spaces between fibers permit airflow. This breathability makes cotton canvas fabric substantially more comfortable than synthetic alternatives for extended wear or use in warm conditions.

The breathability of canvas material proves especially important in shelter applications. A breathable tent made from duck fabric allows moisture vapor to escape, reducing condensation buildup that can lead to dampness and mildew. This property made cotton duck canvas the preferred choice for military tents throughout history.

However, treatments that enhance water resistance—like waxing or synthetic coatings—can reduce breathability. It’s a trade-off: maximum weather protection versus maximum comfort. The best choice depends on your specific application.

The Difference Between Cotton and Duck Cotton

What is the difference between cotton and duck cotton? This question reflects a common misconception. “Duck cotton” or “cotton duck” doesn’t refer to a different type of cotton fiber—rather, it describes a specific weaving method and fabric construction.

All cotton duck fabric begins with regular cotton fibers harvested from cotton plants. The distinction lies in how those fibers are spun into yarn and then woven into fabric. Regular cotton fabric might be woven loosely with single yarns in various weave patterns (twill, satin, knit, etc.). Cotton duck canvas specifically uses a plain weave with plied yarns (or single yarns in single-fill variants) woven very tightly.

Think of it this way: all cotton duck is cotton, but not all cotton is cotton duck. The “duck” designation refers to the construction method, not the raw material. This is why you can have organic cotton duck fabric—it’s the same natural cotton fiber, just grown without pesticides and woven using duck canvas techniques.

Caring for Heavy Duty Canvas

Proper maintenance extends the life of cotton duck fabric significantly. Natural canvas material requires some attention, but the care requirements are straightforward.

Washing: Pre-washing is crucial for untreated cotton canvas fabric by the yard before cutting and sewing. Natural canvas can shrink 8-15% in its first wash. After preshrinking, machine wash in cold water with mild detergent. Avoid bleach, which weakens cotton fibers. Air drying is preferable to prevent excessive shrinkage and wear.

Stain Treatment: The tight weave of duck cloth fabric resists stain penetration, giving you time to address spills. Blot rather than rub, and use appropriate stain removers promptly. For oil-based stains on workwear, pre-treating with dish soap works surprisingly well.

Mildew Prevention: While cotton duck canvas resists mildew better than looser fabrics, it’s not immune. Store canvas material in dry, well-ventilated areas. If mildew appears, brush off what you can outdoors, then wash with a mixture of water and white vinegar.

Waterproofing Maintenance: Waxed canvas and waterproof treatments require periodic renewal. Wax can be reapplied at home using specialized products. For chemically waterproofed canvas cloth, follow manufacturer guidelines for re-treatment.

Sourcing Quality Duck Fabric by the Yard

Finding reliable cotton duck fabric suppliers makes all the difference in project success. Quality varies significantly between suppliers, and the cheapest option isn’t always the best value.

When shopping for duck canvas by the yard, consider these factors:

Weight Accuracy: Reputable suppliers provide accurate weight specifications. Some manufacturers cut corners by producing lighter-weight fabric than labeled. A quality Number 8 duck should truly weigh around 18 ounces per square yard, not 16 or 17.

Yarn Quality: Long-staple cotton produces stronger, smoother duck cloth fabric than short-staple cotton. While harder to verify before purchase, established suppliers typically use better-quality cotton.

Weave Consistency: Examine the fabric closely. The weave should be uniform with consistent tension. Irregularities indicate lower quality control and can affect performance and appearance.

Width Options: Quality suppliers offer various widths to minimize waste and seaming. Common widths range from 36 inches to 144 inches for canvas fabric by the yard.

Treatment Options: Look for suppliers offering treatments like preshrinking, fire retardancy, and water resistance. These value-added services save significant time and ensure proper application.

Color Fastness: For dyed cotton canvas fabric, verify that colors won’t fade excessively with washing and sun exposure. Quality dyes cost more but maintain appearance far better.

Environmental Considerations

The sustainability profile of cotton duck canvas presents both advantages and considerations. As a natural fiber product, cotton duck fabric offers genuine environmental benefits compared to petroleum-based synthetics. The material is biodegradable, renewable, and recyclable at end of life.

However, conventional cotton cultivation involves significant water use and often relies on pesticides. Organic cotton duck canvas addresses these concerns, produced without synthetic pesticides or fertilizers using more sustainable farming practices. While organic options cost more, many users find the environmental benefits worthwhile.

The durability of heavy duty canvas also contributes positively to sustainability. A well-made cotton duck fabric item can last decades with proper care, reducing the need for replacement and minimizing waste. This longevity factor often outweighs the initial resource investment.

Making Your Selection

Choosing the right cotton duck fabric for your project requires matching material properties to intended use. Here’s straightforward guidance based on industry experience:

For Bags and Totes: 10oz single-fill cotton canvas fabric provides an ideal balance of strength, sewability, and cost for everyday bags. Upgrade to 12oz or Number 12 duck for bags carrying heavier loads regularly.

For Upholstery: Number 10 or Number 8 duck cloth fabric offers the structure and durability needed for furniture. Lighter weights won’t hold up; heavier weights become difficult to work with.

For Workwear: Number 8 to Number 6 duck canvas delivers the abrasion resistance and durability demanded by tough work environments. The extra weight pays off in garment longevity.

For Outdoor Gear: Tent construction typically uses Number 10 or Number 8 duck, often with waterproofing treatment. Tarps and covers benefit from Number 6 or Number 4 for maximum weather resistance.

For Art Canvas: Number 12 or Number 10 duck provides an excellent surface for painting. Lighter weights work for small pieces; heavier weights support larger stretched canvases better.

For Home Décor: 10oz to 12oz cotton canvas fabric by the yard suits most decorative applications—curtains, pillows, tablecloths. The material drapes nicely while offering good durability.

For Printed Apparel: Medium-weight canvas (10-12oz) works exceptionally well for screen printing and graphic applications, providing durability while maintaining comfort and printability.

Understanding Canvas in Custom Apparel

At Teebete, we focus on creating high-quality printed apparel that leverages the best properties of cotton and canvas materials. While we don’t supply raw fabric, our expertise in garment construction and printing helps customers understand why fabric choice matters for the final product.

Cotton duck canvas, when used in printed clothing, offers several advantages: the stable surface prevents design distortion during printing, the tight weave prevents ink bleeding, and the durable nature ensures graphics remain vibrant through countless washes. These properties make canvas-based garments ideal for workwear uniforms, promotional apparel, and fashion items where both durability and visual impact matter.

Frequently Asked Questions

What is cotton duck canvas fabric?

Cotton duck canvas fabric is a heavy-duty, tightly woven cotton textile characterized by its plain weave construction using plied yarns. The term “duck” comes from the Dutch word “doek” meaning cloth. This durable canvas material is classified by weight using a numbered system, with applications ranging from workwear and bags to tents and industrial uses. The tight weave creates exceptional strength, abrasion resistance, and longevity, making it one of the most reliable fabric choices for projects requiring durability.

Is cotton duck canvas breathable?

Yes, cotton duck canvas is breathable despite its dense weave. The natural cotton fibers allow air circulation through microscopic spaces in the fabric structure, even in heavier weights. This breathability makes duck cloth fabric comfortable for apparel and ideal for applications like tents where moisture vapor needs to escape. However, waterproofing treatments such as waxing or synthetic coatings can reduce breathability by filling or covering these air passages, creating a trade-off between weather protection and ventilation.

What is the difference between cotton and duck cotton?

There is no difference in the actual cotton fiber itself—”duck cotton” or “cotton duck” refers to a specific fabric construction method, not a different type of cotton plant. All cotton duck fabric is made from regular cotton fibers. The distinction lies in how the cotton is woven: duck canvas uses a tight plain weave with plied yarns (two yarns twisted together) or tightly woven single yarns, creating a heavier, more durable fabric than standard cotton textiles. Think of cotton duck as a construction style rather than a unique material.

What are the properties of duck canvas fabric?

Duck canvas fabric exhibits several key properties that account for its widespread use. These include exceptional durability and abrasion resistance from the tight weave structure, natural breathability from cotton fibers, inherent water resistance that can be enhanced with treatments, excellent dimensional stability that maintains shape under stress, and a smooth surface texture resistant to snagging. The fabric also develops an attractive patina with age while maintaining structural integrity, initially feels stiff but softens beautifully with use, and offers a natural, authentic aesthetic. These combined properties make heavy duty canvas suitable for both functional and decorative applications.

How do I choose the right weight of cotton duck fabric?

Choosing the correct weight depends on your project requirements. For lightweight bags, art canvases, and linings, 7-10oz single-fill works well. Medium-weight projects like upholstery, sturdy bags, and aprons benefit from 10-12oz or Number 12 duck. Heavy-duty applications including work clothes, equipment bags, and tents require Number 10 to Number 6 (15-21oz per square yard). Industrial uses like tarps, sandbags, and conveyor belting need the heaviest options, Number 4 to Number 1 (24-30oz per square yard). Consider also that heavier weights are harder to sew but more durable, while lighter weights are easier to work with but less rugged.

Can cotton duck fabric be waterproofed?

Yes, cotton duck canvas can be waterproofed through various treatment methods. The tight weave provides natural water resistance for light moisture, but full waterproofing requires treatment. Traditional waxing with paraffin or beeswax creates breathable water resistance while developing an attractive patina. Synthetic waterproofing coatings offer more complete protection but reduce breathability. Many fabric suppliers offer pre-treated waterproof canvas material. DIY treatments are also available, though professional applications typically provide more consistent and durable results. Regular re-treatment maintains effectiveness over time.

What is duck material best used for?

Duck material excels in applications requiring durability and strength. Common uses include workwear such as jackets, pants, and overalls; bags of all types from totes to industrial duffels; home furnishings including upholstery, slipcovers, and curtains; outdoor gear like tents, tarps, boat covers, and awnings; footwear from casual shoes to work boots; artist canvases for painting; industrial applications such as equipment covers, drop cloths, and conveyor belting; and accessories including aprons, tool rolls, and craft projects. The specific weight of cotton duck fabric determines suitability—lighter weights for crafts and art, medium weights for furniture and bags, heavy weights for outdoor gear and workwear.

How much does duck canvas shrink?

Untreated natural cotton duck fabric typically shrinks 8-15% in its first wash, with both length and width affected. This shrinkage occurs because the weaving process places tension on cotton fibers, which relax when exposed to water and heat. Heavier weight duck cloth fabric generally experiences less shrinkage than lighter weights due to tighter weave construction. Pre-shrunk canvas material undergoes treatment during manufacturing to minimize further shrinkage, usually reducing it to 3-5%. For best results, always pre-wash cotton canvas fabric by the yard before cutting and sewing projects. Machine wash in cold water and air dry or tumble dry low to minimize shrinkage in finished items.

Summary Table: Cotton Duck Fabric Key Points

| Aspect | Key Information |

|---|---|

| Definition | Heavy-duty, tightly woven cotton fabric with plain weave construction; name derives from Dutch “doek” meaning cloth |

| Primary Material | 100% natural cotton fibers (traditional), though cotton-poly blends exist |

| Weight Classification | Numbered system (1-12, inverse scale) plus ounce-based single-fill (7-24oz); lower numbers = heavier fabric |

| Weave Structure | Plain weave with two yarns in warp, one in weft; tighter than regular canvas |

| Key Properties | Exceptional durability, natural breathability, inherent water resistance, dimensional stability, smooth surface texture |

| Strength Source | Tight weave + plied yarns in numbered ducks create superior abrasion resistance and tear strength |

| Breathability | Yes, despite density; natural cotton allows air circulation; treatments may reduce this |

| Water Resistance | Natural resistance to light moisture; can be enhanced with wax or synthetic treatments for waterproofing |

| Common Weights | Lightweight (7-10oz): crafts, linings, art; Medium (10-15oz): bags, upholstery; Heavy (15-24oz): workwear, outdoor gear; Ultra-heavy (24-30oz+): industrial uses |

| Popular Applications | Workwear, bags, upholstery, outdoor gear, tents, tarps, artist canvas, industrial covers, footwear |

| Shrinkage | 8-15% first wash (untreated); 3-5% (pre-shrunk); always pre-wash before sewing |

| Care Requirements | Machine wash cold, mild detergent; air dry preferred; avoid bleach; store dry to prevent mildew |

| Primary Advantage | Longevity—properly maintained cotton duck fabric can last decades with regular use |

| Sustainability | Natural, biodegradable, renewable; organic options available; durability reduces replacement needs |

| Quality Indicators | Accurate weight, consistent weave, quality cotton yarns, even tension, proper width specifications |

Interested in custom printed apparel using quality cotton and canvas materials? Teebete specializes in creating durable, professionally printed clothing that showcases your designs beautifully. Our understanding of fabric properties ensures your printed garments deliver both visual impact and lasting quality. Whether you need branded workwear, promotional items, or custom fashion pieces, we bring expertise in both materials and printing to every project.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.