Cotton Poplin Fabric Tight Weave Properties & Applications

Understanding the construction and performance characteristics of cotton poplin fabric reveals why this textile has remained a wardrobe essential for centuries. The distinctive tight weave structure of poplin creates a unique combination of durability, elegance, and versatility that few other cotton fabrics can match.

What Is Cotton Poplin Fabric

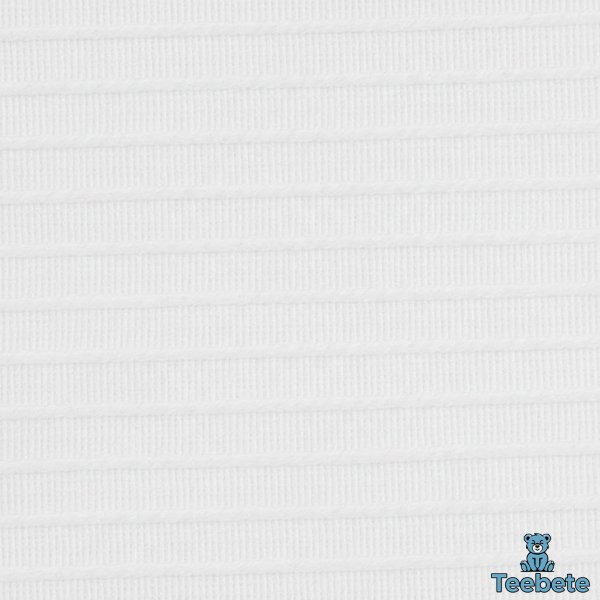

Cotton poplin fabric is a plain-weave textile characterized by fine horizontal ribs that create a smooth, lustrous surface. This poplin fabric distinguishes itself through a specific weaving technique where fine warp yarns intersect with slightly thicker weft yarns. The result is a fabric with exceptional strength and a refined, silky appearance that feels pleasant against the skin.

The defining feature of what is poplin fabric lies in its construction method. Unlike other cotton weaves, poplin cotton fabric employs a tight, balanced plain weave that creates subtle horizontal ribs across the surface. These ribs are often barely visible to the eye but contribute significantly to the fabric’s distinctive hand feel and structural integrity.

From our experience working with customers, the most common question we receive is what material is poplin actually composed of. While 100% cotton poplin represents the traditional composition, modern manufacturing has introduced variations. Pure cotton versions remain the most popular due to their breathability and natural properties, though blends with polyester or elastane now serve specific functional needs.

Historical Evolution of Poplin Material

The history of poplin material dates back to 15th century Avignon, France. Originally known as “papelaine” in reference to the papal town where it originated, this fabric initially combined silk and wool fibers. According to fabric historians at Cimmino, the fabric was reserved exclusively for nobility and religious officials due to its luxurious appearance and expensive production costs.

The transformation from a luxury textile to an everyday essential occurred during the 18th century industrial revolution. Manufacturers discovered that replacing silk and wool with cotton fibers created a more accessible fabric while maintaining the desirable properties. This shift democratized poplin, making it available beyond aristocratic circles.

Modern cotton poplin fabric production has evolved significantly from its historical roots. Today’s manufacturing employs advanced weaving techniques and quality control measures that early craftsmen couldn’t have imagined. Yet the fundamental appeal remains unchanged: a fabric that balances refinement with practicality.

Understanding Tight Weave Cotton Construction

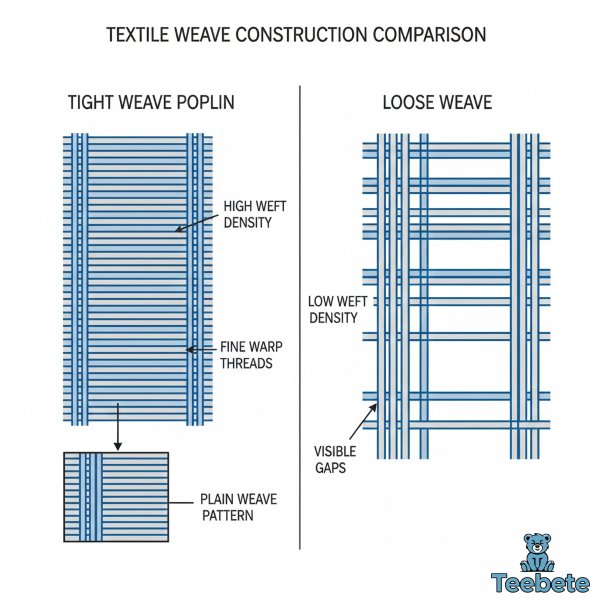

The tight weave structure represents the cornerstone of cotton poplin fabric performance. This construction method involves interlacing warp and weft threads with minimal spacing between each intersection point. The density of this weave directly influences multiple fabric properties, from strength to appearance.

What is tight weave cotton exactly? It refers to fabrics where threads are packed closely together, creating fewer gaps in the textile structure. In poplin cotton fabric, the thread count typically ranges from 100 to 200 threads per inch, though premium versions may exceed these numbers. This density creates a barrier against wind and light while maintaining breathability—a seemingly contradictory combination that tight weave construction achieves remarkably well.

The weaving process for cotton poplin requires precision. Warp yarns (running lengthwise) are held under tension while weft yarns (running crosswise) pass over and under them in a consistent one-over, one-under pattern. The key difference in poplin lies in using finer warp yarns compared to the weft, creating those characteristic subtle ribs that distinguish authentic poplin material from other plain weaves.

Here’s the part most people don’t realize: the tightness of the weave isn’t just about durability. It also affects how colors appear on the finished fabric. The smooth surface created by tight weave cotton reflects light more uniformly, resulting in more vibrant color presentation compared to looser weaves. This makes poplin fabric particularly suitable for bold prints and deep solid colors.

Physical Properties of Cotton Poplin Fabric

Surface Texture and Hand Feel

Cotton poplin fabric presents a distinctive smooth surface with a subtle sheen. When you run your hand across the fabric, you’ll notice a crisp yet soft sensation—neither slippery like satin nor rough like canvas. This balanced texture results from the tight plain weave combined with the natural properties of cotton fibers.

The fabric poplin maintains a structured feel without stiffness. Unlike heavily starched materials, poplin cotton fabric drapes naturally while holding its shape. This property makes it ideal for garments requiring definition without rigidity—think tailored shirts that move with the body rather than constraining it.

Weight and Density Characteristics

Cotton poplin fabric typically weighs between 90 and 130 grams per square meter (GSM), positioning it in the lightweight to medium-weight category. This range provides enough substance for structure while remaining comfortable for extended wear. The fabric’s density contributes to its opacity; quality poplin material won’t be see-through even in lighter colors, a practical consideration often overlooked until it becomes a problem.

In reality, most people overlook the relationship between fabric weight and seasonal appropriateness. Lighter-weight poplin (90-110 GSM) works beautifully for summer garments, providing coverage without overheating. Medium-weight versions (110-130 GSM) offer year-round versatility, suitable for spring jackets or layered winter looks.

Breathability and Moisture Management

Despite its tight weave, cotton poplin fabric maintains excellent breathability. The natural structure of cotton fibers allows air circulation even when woven densely. This property separates cotton poplin from synthetic alternatives that may appear similar but trap heat and moisture against the skin.

The Cotton Incorporated research institute notes that 100% cotton poplin excels at moisture absorption and release. The fabric wicks perspiration away from the skin and allows it to evaporate through the textile structure. This moisture management capability makes poplin fabric a preferred choice for shirts and dresses worn in warm climates or during active use.

Mechanical Properties and Performance

Durability and Wear Resistance

The tight weave construction of cotton poplin fabric directly translates to exceptional durability. According to textile engineering research, tightly woven cotton fabrics demonstrate superior resistance to tearing and fraying compared to loosely constructed alternatives. The interlocked thread structure distributes stress across multiple connection points, preventing single-point failures that lead to tears.

From our experience working with customers who use poplin for uniforms and workwear, the fabric consistently outperforms expectations. Restaurant servers, hotel staff, and retail workers report that poplin cotton fabric garments maintain their appearance through frequent washing and daily wear. The fabric resists pilling—those annoying fiber balls that form on lower-quality textiles—maintaining a professional appearance even after months of use.

Wrinkle Resistance

Cotton poplin fabric demonstrates natural wrinkle resistance superior to many other cotton weaves. The tight plain weave structure helps the fabric spring back to its original form after creasing. While not completely wrinkle-proof like synthetic blends, poplin material holds its shape admirably compared to looser cotton weaves like voile or muslin.

The wrinkle resistance question—does poplin fabric wrinkle—requires a nuanced answer. Yes, cotton poplin will wrinkle if left crumpled in a suitcase or balled up in a laundry basket. However, it wrinkles less readily than many alternatives and responds well to simple smoothing. A light steam or brief tumble in a dryer with a damp towel typically refreshes the fabric without extensive ironing.

Dimensional Stability

Shrinkage represents a common concern with cotton fabrics. Cotton poplin fabric typically shrinks 2-5% during its first wash, primarily in the length direction following the warp threads. This characteristic necessitates pre-washing fabric before sewing projects to ensure finished garments maintain their intended dimensions.

The tight weave structure actually provides some protection against excessive shrinkage. As fabric care experts at Zelouf Fabrics explain, the densely packed threads have less room to contract compared to loosely woven cotton. Quality cotton poplin fabric that has been properly finished during manufacturing may shrink only minimally, particularly when washed in cold water and line dried.

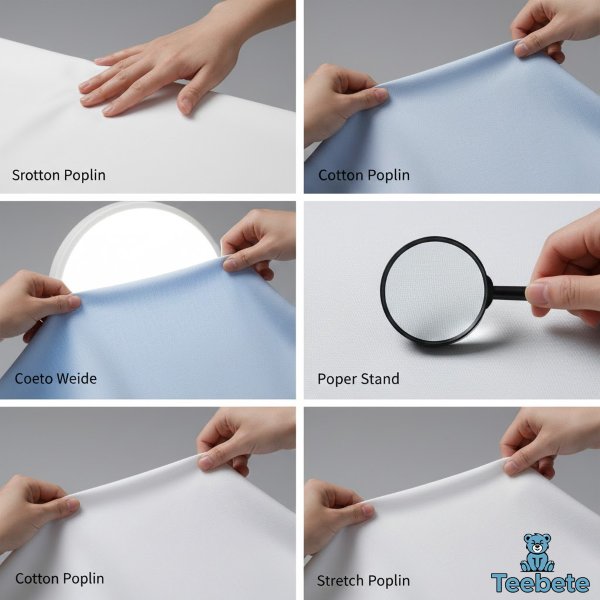

Types and Variations of Poplin Fabric

Pure Cotton Poplin

Traditional 100% cotton poplin represents the original and most popular version of this fabric. Pure cotton poplin fabric offers maximum breathability, natural softness, and excellent moisture absorption. This composition works ideally for clothing items where comfort against the skin takes priority—shirts, dresses, undergarments, and sleepwear.

The quality of pure cotton poplin varies significantly based on the cotton fiber source. Egyptian cotton poplin, made from extra-long staple fibers, provides superior smoothness and durability. Pima cotton offers similar qualities at a more accessible price point. Standard cotton poplin, while more economical, still delivers the fundamental properties that make this fabric valuable for everyday wear.

Stretch Cotton Poplin

Stretch cotton combines cotton poplin with a small percentage of elastane (typically 2-5%). This blend maintains the visual appearance and most characteristics of pure cotton while adding flexibility and shape retention. What is cotton poplin used for when stretch is added? The applications expand significantly—fitted shirts, form-following dresses, and comfortable trousers that move with the body.

The stretch version addresses one limitation of traditional poplin material: its lack of give. While the structured nature of cotton poplin fabric works beautifully for loose or traditionally fitted garments, modern slim-fit styles benefit from the added elasticity. The trade-off comes in slightly reduced breathability and a small decrease in natural cotton’s moisture management properties.

Organic Cotton Poplin Fabric

Organic cotton poplin fabric follows the same construction principles while using cotton grown without synthetic pesticides or fertilizers. This variation appeals to environmentally conscious consumers and those sensitive to chemical residues. The textile performs identically to conventional cotton poplin while supporting more sustainable agricultural practices.

Poly Poplin Fabric and Blended Versions

Polyester poplin and cotton-polyester blends represent a departure from pure cotton while maintaining the poplin weave structure. Poly poplin fabric offers enhanced wrinkle resistance, faster drying, and often lower cost. However, these advantages come at the expense of breathability and natural fiber benefits. Cotton-polyester blends (commonly 65% polyester, 35% cotton or 80% cotton, 20% polyester) attempt to balance both fiber types’ advantages.

Specialty Poplin Variations

Cotton poplin fabric white serves as a foundation for dyeing and printing, making it popular for custom textile applications. Printed poplin showcases vibrant colors and detailed patterns thanks to the smooth surface created by tight weave construction. Yarn-dyed poplin features threads colored before weaving, creating patterns like stripes or checks with superior color permanence.

Poplin Fabric Characteristics: A Comprehensive Analysis

The characteristics of poplin fabric create a unique property profile that explains its enduring popularity. Understanding what are poplin shirts and other garments requires examining how these characteristics translate to finished products.

Structural Characteristics:

- Plain weave construction with fine warp and thicker weft threads

- Subtle horizontal ribbing barely visible to the eye

- Tight thread density with minimal gaps

- Smooth, uniform surface texture

Performance Characteristics:

- Crisp hand feel with natural drape

- Excellent strength relative to weight

- Good dimensional stability with moderate shrinkage

- Natural wrinkle resistance

- Superior color clarity and print definition

Comfort Characteristics:

- Soft against skin despite structured feel

- Excellent breathability for a tight weave

- Effective moisture management

- Lightweight to medium weight for versatile comfort

Care Characteristics:

- Machine washable without special requirements

- Responds well to ironing and pressing

- Resists staining when 100% cotton

- Durable through repeated laundering

This is where things get tricky: balancing all these characteristics requires compromise. A looser weave might increase softness but sacrifices durability. A tighter weave could enhance wind resistance but might reduce breathability. Cotton poplin fabric strikes an optimized balance that explains why it has remained relevant across centuries of changing fashion and textile technology.

Applications of Cotton Poplin Fabric

Apparel Applications

Shirts and Blouses

Cotton poplin fabric has become synonymous with quality shirting. The fabric’s crisp appearance creates the polished look expected in dress shirts while maintaining comfort for all-day wear. What are poplin shirts known for? They’re the gold standard for business attire, offering the structured appearance necessary for professional settings without the stiffness of heavily starched fabrics.

The tight weave of poplin cotton fabric makes it ideal for collars and cuffs that need to hold their shape. Unlike softer cotton weaves that may collapse or curl, poplin maintains the clean lines that define a well-made shirt. This structural integrity extends through numerous wash cycles, ensuring the shirt looks professional even after extensive wear.

Dresses and Skirts

What is cotton poplin used for in women’s fashion extends far beyond blouses. Dresses crafted from this fabric benefit from its ability to hold a defined silhouette while still draping naturally. The medium weight provides enough structure for A-line and fit-and-flare designs without requiring additional interfacing or lining.

Summer dresses particularly benefit from cotton poplin fabric properties. The tight weave provides coverage and wind resistance for outdoor activities while the cotton composition maintains breathability in warm weather. The fabric’s wrinkle resistance means these garments travel well, emerging from suitcases ready to wear with minimal fussing.

Lightweight Jackets and Coats

The poplin material serves excellently for transitional weather outerwear. Spring jackets and windbreakers made from cotton poplin fabric provide protection from breezes and light rain while remaining breathable enough to prevent overheating. The tight weave creates a gentle barrier against elements without the weight and bulk of heavier fabrics.

Uniforms and Workwear

Professional uniforms frequently specify cotton poplin fabric for practical reasons. The fabric withstands frequent industrial laundering while maintaining a neat appearance. Healthcare, hospitality, and service industry workers appreciate poplin cotton fabric for its ability to look fresh throughout long shifts. The fabric resists staining and releases soil easily during washing—crucial properties for work environments where appearance matters.

Home Textile Applications

Bedding and Linens

Cotton poplin fabric creates exceptional bedding characterized by a crisp, hotel-quality feel. Sheets and pillowcases made from this fabric poplin provide a smooth sleeping surface that breathes well through the night. The tight weave helps prevent dust mites and allergens from penetrating the fabric, a benefit for sensitive sleepers.

Table linens benefit from poplin’s ability to hold creases for a formal appearance while releasing food stains readily during washing. The fabric’s durability ensures tablecloths and napkins maintain their appearance through repeated use and laundering.

Curtains and Drapery

The opacity and structure of cotton poplin fabric make it suitable for window treatments. Curtains hang with clean lines and provide privacy without requiring blackout linings in many cases. The fabric’s moderate weight drapes beautifully while remaining easy to manipulate for pleating or gathering.

Specialty Applications

Lining Material

Poplin cotton fabric serves as an ideal lining for jackets, coats, and bags. The smooth surface allows outer garments to slide on and off easily while the breathability prevents the trapped feeling some synthetic linings create. The tight weave provides a barrier between outer fabric and body without adding significant bulk.

Craft and Quilting Projects

Cotton poplin by the yard has become increasingly popular in the quilting and crafting communities. The fabric’s stability makes it easier to work with than loosely woven alternatives. It holds precise seam allowances without fraying excessively and accepts quilting stitches without puckering.

Face Coverings and Protective Gear

Recent years have highlighted cotton poplin fabric’s utility for fabric face masks and similar protective items. The tight weave provides filtration capabilities while maintaining breathability for comfortable extended wear. Research from textile experts studying protective fabrics identified poplin as one of the most effective tightly woven cotton fabrics for this application.

Quality Assessment and Selection Criteria

Identifying Quality Cotton Poplin Fabric

Selecting high-quality cotton poplin fabric requires understanding several key indicators. Thread count provides one measure, though it shouldn’t be the sole consideration. Quality poplin typically ranges from 100-200 threads per inch, with higher counts generally indicating finer yarns and a smoother finish.

Weight consistency matters more than many realize. Hold the fabric up to light—quality poplin material should show minimal variation in opacity across the yardage. Thin spots or streaks indicate inconsistent yarn or weaving problems that will affect performance and appearance.

The hand feel test reveals much about poplin cotton fabric quality. High-quality poplin feels smooth and slightly crisp without feeling papery or stiff. The fabric should have some body—it shouldn’t collapse limply when draped but shouldn’t stand up stiffly either. This balanced hand results from proper yarn selection and appropriate finishing processes.

Understanding Grammage and Weight

When purchasing cotton poplin by the yard, grammage (GSM – grams per square meter) provides valuable information about the fabric’s suitability for intended applications. Lightweight poplin (90-110 GSM) works well for summer dresses, shirts, and scarves. Medium-weight versions (110-130 GSM) suit year-round shirts, professional wear, and home textiles.

The relationship between weight and quality isn’t linear—heavier doesn’t necessarily mean better. The appropriate weight depends on the intended use. Lightweight poplin fabric for a summer blouse should feel different from material destined for upholstery or heavy-duty workwear.

Evaluating Composition

What material is poplin made from matters significantly for performance. When purchasing, check fiber content carefully. Pure cotton provides maximum breathability but may wrinkle more readily. Cotton-polyester blends offer easier care but less natural comfort. Stretch versions add flexibility but may have reduced durability compared to pure cotton alternatives.

At Teebete, we’ve observed that customers often underestimate the importance of fiber quality within the same composition category. Not all 100% cotton poplin performs identically. Egyptian and Pima cotton versions offer superior softness and durability compared to standard cotton, justifying their higher price for applications where quality matters.

Color Fastness and Finishing

Quality poplin fabric maintains its color through repeated washing. Testing before purchase isn’t always possible, but reputable suppliers provide information about dye methods and colorfastness ratings. Yarn-dyed fabrics generally show better color retention than piece-dyed alternatives, though modern printing technologies have narrowed this gap for solid colors.

The finishing processes applied during manufacturing significantly impact final fabric characteristics. Mercerization enhances cotton poplin fabric’s luster and color absorption. Sanforization controls shrinkage, ensuring dimensional stability. Ask suppliers about finishing treatments to understand how the fabric will perform.

Care and Maintenance of Cotton Poplin Fabric

Washing Guidelines

Cotton poplin fabric responds well to standard washing procedures, but following specific guidelines extends fabric life and maintains appearance. Pre-washing new fabric before sewing addresses potential shrinkage, preventing disappointment when finished garments change size after their first wash.

For regular laundering, cold or warm water (below 104°F/40°C) preserves fabric integrity while effectively removing soil. Hot water may enhance cleaning but accelerates color fading and increases shrinkage risk. Gentle or normal cycles work equally well—the durable construction of poplin cotton fabric withstands regular agitation without damage.

Turn garments inside out before washing to protect the outer surface from abrasion. This simple step prevents pilling and maintains the smooth finish characteristic of quality poplin material. Use mild detergents without optical brighteners for colored fabrics to prevent premature fading.

Drying Methods

Line drying represents the gentlest method for cotton poplin fabric and prevents shrinkage most effectively. Hang garments on a clothesline or drying rack away from direct sunlight, which can fade colors. Smooth fabric with your hands while still damp to minimize wrinkles—many pieces will need little to no ironing after this treatment.

Machine drying works well for poplin cotton fabric when time constraints make line drying impractical. Use low to medium heat and remove garments while still slightly damp to reduce wrinkles. The tight weave structure helps poplin fabric withstand tumble drying better than many cotton alternatives.

Ironing and Pressing

Cotton poplin fabric accepts ironing readily, achieving crisp results that define the fabric’s aesthetic appeal. Iron while the fabric retains slight dampness from washing or use a steam iron for best results. Set the iron to cotton temperature (typically the highest setting, around 400°F/204°C).

Press from the wrong side when possible to prevent shine on dark colors. For shirts and structured garments, press the collar first, then cuffs, sleeves, back, and front panels in that order. This sequence prevents re-wrinkling previously pressed sections.

Stain Removal

The tight weave of cotton poplin fabric provides some natural stain resistance—liquids bead on the surface initially rather than immediately penetrating. This characteristic gives you time to blot spills before they set. For fresh stains, blot (never rub) with a clean, white cloth to absorb excess liquid.

According to stain removal experts at Cotton Incorporated, 100% cotton poplin releases stains more readily than many fabrics. Treat stains promptly with appropriate removers based on the stain type. Most common stains respond to gentle pre-treatment with liquid laundry detergent or stain remover followed by normal washing.

Storage Recommendations

Store cotton poplin fabric and garments in cool, dry locations away from direct sunlight. Fold items along natural seam lines to minimize creasing. For long-term storage, use breathable cotton garment bags rather than plastic, which can trap moisture and promote mildew growth.

Hanging works well for jackets and dresses but may cause shoulder dimples in shirts over time. If hanging shirts, use appropriate-sized hangers that support the shoulder line without stretching. Button the top button to help the collar maintain its shape.

Cotton Poplin Fabric in Sustainable Fashion

Environmental Considerations

The sustainability of cotton poplin fabric begins with fiber sourcing. Conventional cotton production uses significant water resources and often involves synthetic pesticides and fertilizers. These inputs create environmental impacts that conscientious consumers increasingly consider when making purchasing decisions.

Organic cotton poplin fabric addresses some of these concerns through cultivation methods that avoid synthetic chemicals. While organic cotton still requires substantial water, improved farming practices and regional water availability considerations have made organic cotton production more sustainable than previously.

The durability of cotton poplin fabric contributes positively to sustainability equations. Garments that last through years of regular wear reduce the need for frequent replacement. This longevity, combined with cotton’s biodegradability at end-of-life, positions poplin favorably compared to synthetic alternatives that may resist degradation for decades or centuries.

Teebete’s Approach to Sustainable Poplin

The textile industry is evolving toward more responsible practices, and cotton poplin fabric suppliers play crucial roles in this transformation. Certification programs like GOTS (Global Organic Textile Standard) and OEKO-TEX provide verification that fabrics meet environmental and safety criteria. These certifications offer consumers assurance that their fabric choices align with their values.

Choosing cotton poplin fabric from responsible suppliers supports incremental improvements in textile sustainability. While no fabric production is impact-free, conscious purchasing decisions drive industry-wide improvements in environmental performance.

Common Questions About Cotton Poplin Fabric

Is Cotton Poplin a Stiff Fabric?

Cotton poplin fabric occupies a middle ground between stiff and soft. The tight weave creates structure that gives poplin a crisp hand feel, but this shouldn’t be confused with actual stiffness. The fabric maintains body while remaining flexible and comfortable against the skin. Think of it as having structure rather than stiffness—the fabric holds its shape without being rigid or uncomfortable.

The perceived stiffness of poplin cotton fabric varies based on weight, finishing treatments, and whether it has been washed. New fabric fresh from the bolt may feel crisper than the same material after laundering, which softens the hand feel while maintaining structural properties.

What Are the Benefits of Cotton Poplin Fabric?

Cotton poplin fabric offers a compelling combination of properties that explain its enduring popularity:

Durability: The tight weave construction creates a fabric that withstands regular use and frequent washing while maintaining its appearance. This longevity makes poplin material economically sensible despite potentially higher initial cost compared to lower-quality alternatives.

Versatility: Few fabrics transition as seamlessly from casual to formal applications. The same cotton poplin fabric that works for weekend dresses serves equally well for professional attire.

Comfort: Despite its structured appearance, poplin fabric breathes well and feels comfortable against skin. The cotton composition provides natural temperature regulation that synthetic alternatives cannot match.

Appearance: The smooth surface and subtle sheen of poplin cotton fabric create a polished, professional look. Garments made from this fabric maintain a neat appearance throughout the day without constant adjustment or fussing.

Care Simplicity: Cotton poplin fabric doesn’t require dry cleaning or special handling. Machine washing and straightforward ironing keep garments looking fresh without professional intervention.

Color Vibrancy: The tight, smooth surface accepts dyes beautifully, resulting in clear, vibrant colors and sharp print definition. This property makes poplin fabric ideal for both solid colors and printed designs.

What Are the Characteristics of Poplin Fabric?

The characteristics of poplin fabric create a distinctive property profile:

The plain weave construction with fine warp yarns and slightly thicker weft yarns creates subtle horizontal ribs that characterize authentic poplin material. This construction method distinguishes poplin from other plain weave cotton fabrics.

The smooth, lustrous surface results from tight thread density and fine yarns. This smoothness contributes to poplin’s professional appearance and makes it suitable for applications requiring visual refinement.

Crisp hand feel balances structure with flexibility. Poplin fabric holds its shape without stiffness, drapes naturally while maintaining body, and feels substantial without heaviness.

Medium weight (typically 90-130 GSM) provides year-round versatility. Unlike heavier fabrics limited to cold weather or sheer fabrics restricted to summer, cotton poplin fabric serves across seasons.

Natural wrinkle resistance means garments maintain their appearance through normal wear without constant attention. While not wrinkle-proof, poplin performs better than many cotton alternatives in this regard.

What Is Tight Weave Cotton?

Tight weave cotton refers to fabrics where threads are closely packed with minimal spacing between intersections. This construction creates several important properties:

Reduced Porosity: The dense thread structure limits air gaps, creating a more substantial barrier against wind, light, and small particles while maintaining breathability through fiber structure.

Enhanced Durability: Closely spaced threads distribute stress across more connection points, reducing the likelihood of individual thread failures that lead to tears or runs.

Improved Surface Smoothness: Tight weave construction creates a more uniform surface with fewer irregularities. This smoothness benefits both appearance and comfort.

Better Color Definition: The reduced gaps between threads create a more uniform canvas for dyes and prints, resulting in sharper, more vibrant colors.

Cotton poplin fabric exemplifies tight weave construction, demonstrating how this approach creates practical, versatile textiles suitable for diverse applications.

Does Poplin Fabric Wrinkle Easily?

Poplin fabric demonstrates natural wrinkle resistance superior to many cotton alternatives, though it doesn’t match the complete wrinkle-free performance of heavily treated synthetics. The tight plain weave helps fabric spring back to its original form after mild creasing. This recovery happens naturally without intervention—simply hanging wrinkled poplin material often allows creases to relax overnight.

However, deep folds from tight packing or prolonged compression require intervention. The good news: cotton poplin fabric responds excellently to ironing and steaming. A brief pass with an iron or exposure to steam restores the crisp appearance that makes poplin material desirable for professional wear.

When traveling with poplin garments, roll items rather than folding to minimize creasing. Hang pieces immediately upon arrival and run a hot shower to create steam in the bathroom. Many wrinkles will relax in this steamy environment without touching an iron.

Can You Wash Cotton Poplin Fabric?

Cotton poplin fabric not only can be washed but actually improves with washing in many cases. The initial crisp finish that characterizes new fabric softens slightly after the first few washes, creating a more comfortable hand feel while maintaining structural properties.

Machine washing works perfectly for cotton poplin. Use cold or warm water with regular laundry detergent. The durable construction withstands normal washing cycles without damage—no need for delicate settings unless garment construction includes fragile trims or decorations.

Is Cotton Poplin Suitable for Summer Wear?

Cotton poplin fabric excels for warm weather clothing. The natural breathability of cotton combines with a tight weave structure that provides coverage without overheating. This combination makes poplin cotton fabric ideal for summer dresses, shirts, and lightweight jackets.

The smooth surface doesn’t cling to skin the way some fabrics do in humid conditions. Moisture wicks away from the body and evaporates through the fabric structure, maintaining comfort during active wear or high temperatures. Many people discover that cotton poplin outperforms synthetic “performance” fabrics for all-day summer comfort.

How Does Cotton Poplin Compare to Other Fabrics?

Cotton Poplin vs. Twill: While both are tight weaves, twill creates diagonal ribs through its construction while poplin forms horizontal ribs. Twill typically feels slightly thicker and has more texture. Poplin offers a smoother surface and lighter weight suitable for shirts and dresses where twill might feel too heavy.

Cotton Poplin vs. Oxford Cloth: Oxford cloth uses a basket weave (multiple threads crossing multiple threads) creating a textured appearance. Poplin’s plain weave creates a smoother, more refined surface. Oxford works well for casual shirts while poplin fabric suits both casual and formal applications.

Cotton Poplin vs. Broadcloth: These terms sometimes overlap depending on regional usage. Technically, broadcloth uses finer yarns creating an even smoother surface than poplin. In practice, many retailers use these terms interchangeably for similar fabrics.

Cotton Poplin vs. Voile: Voile uses a much looser plain weave, creating a lightweight, semi-sheer fabric. Poplin’s tight weave provides opacity and structure that voile lacks, making them suitable for different applications despite both being plain weave cotton fabrics.

Working with Cotton Poplin Fabric: Sewing and Construction

Cutting and Preparation

Pre-wash cotton poplin fabric before cutting to address shrinkage. This crucial step prevents finished garments from changing size after their first wash. Wash using the same method you’ll use for the finished item—hot water and machine drying if that’s your plan, or cold water and line drying if you prefer gentler treatment.

Press fabric thoroughly before cutting. The smooth surface of poplin material makes accurate cutting essential—any waviness in the fabric will translate to finished garment fit issues. Use a rotary cutter and clear ruler for the most precise cuts on straight edges. Sharp fabric scissors work better for curved areas.

Sewing Techniques

Cotton poplin fabric sews beautifully on standard home sewing machines. Use universal needles in size 70/10 to 80/12 for most weights. The tight weave requires sharp needles to penetrate cleanly without causing runs or snags. Replace needles after every 8-10 hours of sewing to maintain optimal performance.

Standard stitch length (2.5mm) works well for most applications. Reduce to 2.0mm for fine detail work or increase slightly for basting or gathering. The fabric’s low stretch means standard straight stitches provide adequate seam strength without requiring stretch stitches.

Seam Finishing

The tight weave of cotton poplin fabric means it frays less readily than looser cotton weaves, but seam finishing still improves garment longevity and appearance. French seams work beautifully with poplin’s crisp nature, creating clean enclosed seams ideal for unlined garments. Serging or zigzag stitching provides adequate finishing for enclosed seams or casual garments.

Pressing During Construction

Press seams as you sew for professional results. The poplin cotton fabric responds excellently to heat and pressure, accepting crisp creases that define garment details. Use steam liberally—unlike some delicate fabrics, cotton poplin benefits from moisture during pressing.

Commercial Applications and Industry Use

Hospitality and Service Industries

Cotton poplin fabric dominates uniform specifications across hospitality sectors. Hotels, restaurants, and catering services appreciate poplin’s ability to maintain a professional appearance through long shifts and frequent industrial laundering. The fabric resists staining and releases soil readily during washing—critical properties when appearance directly impacts customer perception.

The cost-to-performance ratio makes poplin material economically sensible for commercial applications. While not the cheapest fabric option, its durability means uniforms last longer, reducing replacement frequency and overall program costs.

Healthcare Settings

Medical and dental professional uniforms increasingly specify cotton poplin fabric. The tight weave provides some protection against fluid penetration while maintaining breathability for comfort during long shifts. The fabric withstands high-temperature washing and bleaching required for proper sanitization in healthcare environments.

Corporate Apparel

Corporate uniform programs favor cotton poplin for dress shirts and blouses. The fabric’s professional appearance aligns with brand image requirements while the durability justifies investment in quality garments that represent the company well over extended use periods.

Retail and Merchandising

Retail environment demands—frequent customer interaction, constant movement, and all-day wear—align perfectly with cotton poplin fabric properties. Store associates appreciate garments that look fresh at closing time without requiring mid-shift changes or constant adjustment.

Innovation and Future Developments

Performance Enhancements

Textile innovation continues evolving cotton poplin fabric capabilities. Water-repellent treatments now available for poplin material add functionality without significantly compromising breathability. These treatments work by altering how liquid interacts with fiber surfaces rather than creating impermeable barriers.

Anti-microbial treatments extend garment freshness between washes, particularly valuable for active wear applications. These treatments inhibit bacterial growth that causes odor, allowing poplin cotton fabric garments to be worn multiple times before requiring laundering.

Sustainable Manufacturing Advances

Manufacturing efficiency improvements reduce cotton poplin fabric production’s environmental footprint. Closed-loop dyeing systems recycle water and capture unused dye, dramatically reducing waste compared to traditional methods. These innovations make cotton poplin fabric production more environmentally responsible without sacrificing quality or performance.

Digital printing technologies now allow for precise application of colors and patterns to poplin material, using only the dye necessary for the design. This targeted approach eliminates the waste associated with traditional printing methods where excess dye is washed away after application.

Waterless finishing techniques represent another breakthrough in poplin cotton fabric production. These methods use supercritical carbon dioxide or plasma treatments instead of water-based processes, reducing water consumption while achieving the same smooth finish that characterizes quality poplin fabric.

Fiber Innovation

Research into improved cotton varieties focuses on developing plants that require less water and resist pests naturally. These agricultural innovations reduce the environmental impact of growing cotton for poplin material while maintaining fiber quality. The resulting fabric performs identically to conventional cotton poplin but carries a lighter environmental footprint from field to finished textile.

Recycled cotton blends now appear in some cotton poplin fabric offerings. These fabrics incorporate fibers reclaimed from textile waste, reducing demand for virgin cotton. While recycled content may slightly alter hand feel compared to 100% new fiber poplin, the differences diminish with advancing recycling technologies.

The Teebete Perspective on Cotton Poplin Excellence

At Teebete, we’ve built our reputation on understanding what makes cotton poplin fabric exceptional. Our commitment to quality begins with fiber selection and extends through every manufacturing stage. We recognize that customers choosing poplin cotton fabric invest in garments and projects that matter—business attire that must perform through demanding workdays, special occasion dresses that create lasting memories, or home textiles that provide daily comfort for years.

This understanding drives our rigorous quality standards. Every bolt of cotton poplin fabric we offer undergoes testing to verify it meets specifications for thread count, weight, colorfastness, and dimensional stability. We don’t accept compromises because we know our customers depend on consistent quality for their projects and businesses.

Regional Variations and Global Production

Manufacturing Centers

Cotton poplin fabric production occurs worldwide, with major manufacturing centers in China, India, Pakistan, Turkey, and Italy. Each region brings different strengths to poplin material production. Indian mills excel at producing affordable cotton poplin for mass market applications. Italian manufacturers focus on premium poplin fabrics using the finest cotton and most sophisticated finishing techniques.

Understanding production origin helps assess quality and price relationships. Premium cotton poplin fabric from established European mills commands higher prices but often justifies the investment through superior hand feel, more precise manufacturing, and better consistency between dye lots.

Quality Standards Across Regions

Manufacturing standards vary significantly between regions. European mills generally adhere to stricter environmental and labor regulations, factors reflected in pricing. Asian production spans the quality spectrum from economy fabrics suitable for disposable fashion to premium textiles rivaling European quality at more accessible prices.

When purchasing cotton poplin by the yard or in bulk, understanding these regional differences helps make informed decisions balancing quality requirements against budget constraints. The “best” choice depends on intended application—economy poplin works perfectly for craft projects or casual wear where ultimate refinement matters less than cost, while investment in premium fabric makes sense for heirloom sewing or professional wardrobes.

Market Trends and Consumer Preferences

The Return to Natural Fibers

Consumer interest in natural fibers has driven increased demand for cotton poplin fabric over synthetic alternatives. Awareness of microplastic pollution from synthetic textiles washing has motivated many consumers to choose cotton for environmental reasons. The breathability and comfort advantages of cotton poplin reinforce this trend even among consumers less focused on sustainability.

Slow Fashion Movement

The slow fashion philosophy emphasizes quality over quantity, encouraging investment in well-made garments that last for years rather than seasonal disposables. Cotton poplin fabric aligns perfectly with this mindset. Its durability and timeless appeal make it ideal for building capsule wardrobes focused on versatile, long-lasting pieces.

Customization and DIY Culture

Growing interest in sewing and textile crafts has expanded the home sewing market for cotton poplin by the yard. Social media platforms showcase successful projects using poplin material, inspiring others to explore garment construction. This trend benefits from poplin’s forgiving nature—the fabric’s stability and moderate stretch make it manageable for intermediate sewers while delivering professional-looking results.

Troubleshooting Common Issues

Addressing Puckered Seams

Seam puckering in cotton poplin fabric typically results from thread tension issues or using needles too large for the fabric weight. Reduce upper thread tension slightly and ensure you’re using appropriate needle size (70/10 to 80/12 for most poplin weights). The tight weave magnifies tension problems that might be invisible in looser fabrics.

Preventing Color Bleeding

While quality cotton poplin fabric should be colorfast, darker colors occasionally bleed during first washing. Wash new fabric separately or with like colors initially. Adding half a cup of white vinegar to the rinse cycle helps set dye and prevents future bleeding without affecting fabric hand feel.

Managing Static Electricity

Cotton naturally resists static buildup compared to synthetic fibers, but dry climates or low humidity can cause static in cotton poplin fabric. Adding fabric softener to the rinse cycle or using dryer sheets reduces static. For garments already experiencing static, lightly misting the inside with water from a spray bottle provides immediate relief.

Dealing with Stubborn Wrinkles

Persistent wrinkles in poplin cotton fabric respond to steam treatment. Hang the garment in a steamy bathroom or use a handheld steamer. For severe creasing, dampen the fabric slightly before ironing at cotton temperature setting. The combination of moisture and heat relaxes fibers, releasing even stubborn creases.

Buying Guide: Making Informed Purchasing Decisions

Questions to Ask Suppliers

When purchasing cotton poplin fabric, whether by the yard or in bulk, asking specific questions helps ensure you receive material suitable for your needs:

What is the fiber content? Verify whether the fabric is 100% cotton, a cotton blend, or contains stretch fibers. This affects performance, care requirements, and suitability for your project.

What is the fabric weight? Request GSM (grams per square meter) specifications to ensure the fabric weight matches your intended application.

Has the fabric been pre-shrunk? Understanding shrinkage expectations prevents disappointment with finished project dimensions.

What finishing treatments have been applied? Mercerization, sanforization, and other treatments affect fabric properties and performance.

What are the colorfastness ratings? Important for items that will be laundered frequently or exposed to sunlight.

Evaluating Samples

Whenever possible, request samples before committing to large purchases of cotton poplin by the yard. Physical samples reveal properties that specifications and photographs cannot fully convey. Assess hand feel, drape, opacity, and color accuracy. Perform a simple shrinkage test by measuring a sample piece, washing it according to intended care methods, and re-measuring after drying.

Price vs. Quality Considerations

Cotton poplin fabric pricing varies dramatically based on cotton quality, manufacturing standards, and finishing treatments. The cheapest option rarely represents the best value for projects where quality matters. Conversely, premium pricing doesn’t automatically guarantee superior performance—reputation and specifications matter more than price alone.

For projects requiring significant yardage, the cost difference between economy and mid-range poplin material may be substantial. However, the improved durability and appearance of better fabric often justify the investment through longer garment life and better wearing experience.

Frequently Asked Questions

What are the characteristics of poplin fabric?

Poplin fabric characteristics include a plain weave construction with subtle horizontal ribs, smooth lustrous surface, crisp yet soft hand feel, and medium weight typically between 90-130 GSM. The tight weave creates excellent durability while maintaining breathability. Cotton poplin fabric demonstrates natural wrinkle resistance, holds dye beautifully for vibrant colors, and provides versatile performance across seasons. The structured nature gives garments definition without stiffness, making poplin material suitable for both casual and formal applications.

What is tight weave cotton?

Tight weave cotton refers to fabrics where threads are densely packed with minimal spacing between intersections. This construction method creates several beneficial properties including enhanced durability through stress distribution across multiple connection points, improved surface smoothness for better appearance and comfort, reduced porosity providing wind resistance while maintaining breathability through fiber structure, and superior color definition resulting from the uniform surface. Cotton poplin fabric exemplifies tight weave construction, demonstrating how closely packed threads create practical, versatile textiles. The tight weave in poplin cotton fabric balances structure with flexibility, offering the refined appearance desired in quality garments.

What are the benefits of cotton poplin fabric?

Cotton poplin fabric delivers exceptional durability through its tight weave construction, withstanding regular use and frequent washing while maintaining appearance. The versatility spans casual to formal applications—the same fabric works equally well for weekend dresses and professional attire. Comfort comes from cotton’s natural breathability combined with the smooth texture that feels pleasant against skin. The polished appearance featuring subtle sheen creates a professional look without constant maintenance. Care simplicity allows machine washing and straightforward ironing without special handling or dry cleaning. The smooth, tight surface accepts dyes beautifully, producing vibrant colors and sharp print definition. These combined benefits explain why poplin material has remained popular across centuries of changing fashion.

Is cotton poplin a stiff fabric?

Cotton poplin fabric is not stiff but rather structured. The tight weave creates body and crispness that holds shape without rigidity. Think of poplin as having intentional structure rather than stiffness—the fabric maintains definition while remaining flexible and comfortable against skin. The perceived crispness varies based on fabric weight, finishing treatments, and whether it has been washed. New poplin cotton fabric fresh from the bolt may feel crisper than the same material after laundering, which softens the hand while preserving structural properties. This balance makes cotton poplin fabric ideal for garments requiring polished appearance with all-day comfort—crisp enough for professional settings yet flexible enough for unrestricted movement.

Does cotton poplin shrink?

Cotton poplin fabric typically shrinks 2-5% during first washing, primarily in the length direction following the warp threads. This characteristic makes pre-washing essential before sewing projects to ensure finished garments maintain intended dimensions. The tight weave structure actually provides some protection against excessive shrinkage compared to loosely woven cotton—the densely packed threads have less room to contract. Quality poplin material that has been properly finished during manufacturing may shrink minimally, particularly when washed in cold water and line dried. To control shrinkage in finished garments, use cold water washing and avoid high heat drying. The fabric stabilizes after initial shrinkage, maintaining dimensions through subsequent washing cycles when properly cared for.

Can you use cotton poplin for quilting?

Cotton poplin fabric works excellently for quilting projects. The fabric’s stability makes it easier to work with than loosely woven alternatives—it holds precise seam allowances without excessive fraying and accepts quilting stitches without puckering. The smooth surface creates clean, defined patterns in pieced designs. The medium weight provides substance without excessive bulk in seams, important when multiple fabric layers come together. Many quilters appreciate how cotton poplin by the yard offers consistent quality and wide color selection. The tight weave also contributes to quilt durability, ensuring projects withstand regular use and washing. While traditional quilting cotton remains popular, poplin cotton fabric provides an excellent alternative, particularly for projects where a crisper hand feel and more structured drape are desired.

What’s the difference between poplin and broadcloth?

Poplin fabric and broadcloth share similarities but have distinct differences. Poplin features subtle horizontal ribs created by using finer warp yarns with slightly thicker weft yarns. Broadcloth typically employs yarns of similar size in both directions, creating an even smoother surface without the characteristic ribbing. The terminology sometimes overlaps in commercial usage, with retailers occasionally using these terms interchangeably for similar fabrics. Generally, broadcloth uses finer yarns overall, resulting in an even softer, smoother finish than poplin. Both are plain weave cotton fabrics suitable for shirts and dresses, but poplin material tends to have slightly more body and structure. For practical purposes, either works well for similar applications, with choice often coming down to personal preference regarding texture and hand feel rather than fundamental performance differences.

How do you prevent cotton poplin from wrinkling?

While cotton poplin fabric has natural wrinkle resistance superior to many cotton alternatives, preventing wrinkles requires proper handling. Remove garments from the washing machine promptly and either hang immediately or tumble dry on low heat, removing while slightly damp. When traveling, roll poplin garments rather than folding to minimize creasing. For storage, hang shirts and dresses on appropriate hangers that support shoulder lines without stretching. If wrinkles do form, the fabric responds excellently to steam—hang items in a steamy bathroom or use a handheld steamer for quick refreshing. The tight weave structure helps poplin cotton fabric spring back to smooth form with minimal intervention. For stubborn wrinkles, iron at cotton temperature setting while fabric retains slight dampness or use steam iron. The key is addressing wrinkles promptly rather than allowing deep creases to set over time.

Summary Table: Cotton Poplin Fabric Key Properties

| Property Category | Characteristics | Practical Implications |

|---|---|---|

| Construction | Plain weave with fine warp, thicker weft threads; tight thread density 100-200 threads per inch | Creates subtle horizontal ribs, smooth surface, enhanced durability |

| Weight Range | 90-130 GSM typical range | Lightweight versions (90-110 GSM) for summer; medium weight (110-130 GSM) year-round |

| Hand Feel | Smooth, crisp texture with natural drape; structured without stiffness | Professional appearance with comfort; holds shape while remaining flexible |

| Breathability | Excellent air circulation despite tight weave; natural cotton moisture wicking | Comfortable for extended wear; suitable for warm weather applications |

| Durability | Superior tear resistance; resists pilling and fraying | Long garment life; withstands frequent washing and daily wear |

| Wrinkle Resistance | Natural recovery from mild creasing; responds well to steam and ironing | Low maintenance; maintains neat appearance with minimal fussing |

| Shrinkage | 2-5% typical in first wash, primarily lengthwise | Pre-washing essential for sewing projects; stabilizes after initial shrinkage |

| Care Requirements | Machine washable; accepts ironing at cotton temperature; no dry cleaning needed | Easy home care; cost-effective maintenance over garment lifetime |

| Color Properties | Smooth surface accepts dyes beautifully; excellent print definition | Vibrant colors; sharp patterns; good colorfastness with quality dyeing |

| Seasonal Suitability | Year-round versatility; particularly good for warm weather | Single fabric type serves multiple seasons; cost-effective wardrobe building |

| Primary Applications | Dress shirts, blouses, dresses, lightweight jackets, uniforms, bedding | Professional wear, casual clothing, home textiles, craft projects |

| Price Range | Varies by cotton quality and finishing; economy to premium options available | Good value across price points when quality matches intended use |

Conclusion: The Enduring Appeal of Cotton Poplin Fabric

Cotton poplin fabric has maintained its position as a textile staple for good reason. The tight weave construction creates a remarkable balance of properties rarely found in a single fabric—durability without heaviness, structure without stiffness, refinement without delicacy. This combination makes poplin material genuinely versatile rather than merely adequate for multiple uses.

Understanding what is cotton poplin fabric and how its construction influences performance empowers better purchasing and usage decisions. Whether selecting cotton poplin by the yard for a sewing project, choosing garments for a professional wardrobe, or specifying uniforms for commercial applications, knowledge of the fabric’s characteristics ensures expectations align with reality.

The future of cotton poplin fabric looks promising. Sustainable manufacturing advances address environmental concerns while innovations in finishing treatments expand functionality. Yet the fundamental appeal remains unchanged from the fabric’s origins centuries ago—cotton poplin creates garments and textiles that look polished, feel comfortable, and last through regular use.

From our experience at Teebete working with textile professionals, home sewers, and commercial buyers, we’ve observed that those who take time to understand cotton poplin fabric become loyal advocates. The fabric’s reliable performance and versatile nature make it a sensible choice across applications. Whether you’re new to working with poplin cotton fabric or have years of experience, appreciating the relationship between construction and performance enhances every project and purchase.

The next time you slip into a crisp cotton poplin shirt or admire the drape of a poplin dress, you’ll recognize the centuries of textile evolution and modern manufacturing expertise that created that particular combination of comfort, durability, and refined appearance. That’s the quiet excellence of cotton poplin fabric—delivering reliable performance without demanding attention, supporting your daily activities while maintaining a polished presence from morning through evening.

For more information about cotton poplin fabric selection, quality assessment, or specific application guidance, the textile community offers extensive resources. Understanding this versatile material opens possibilities for creating garments and projects that combine practical performance with aesthetic appeal—the hallmark of truly successful textile choices.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.