Screen Printed T-Shirt Care Complete Washing Guide

Custom screen printed t-shirts are more than just garments—they’re wearable expressions of personality, memories, and creativity. Whether you’ve invested in custom designs from Teebete or other quality printers, proper care ensures your favorite printed tees maintain their vibrant colors and crisp designs for years to come. Understanding how to wash screen printed shirts properly can mean the difference between a shirt that lasts dozens of washes and one that fades or cracks prematurely.

This comprehensive screen print care guide will walk you through everything you need to know about preserving your graphic shirt maintenance, from understanding the science behind plastisol ink care to mastering the best washing techniques for custom t-shirt care.

Understanding Screen Printed T-Shirts: The Foundation of Proper Care

Before diving into washing instructions, it’s essential to understand what makes screen printed clothing unique. Screen printing involves transferring ink through a fine mesh screen onto fabric, creating layers of vibrant, durable designs. The most common ink used in this process is plastisol ink—a PVC-based material that sits on top of the fabric rather than soaking into it.

According to industry experts, plastisol inks bond mechanically with fabric fibers and must be properly cured at temperatures between 300-330°F to achieve maximum durability. When properly cured during the printing process, these inks create prints that can withstand hundreds of washes without significant deterioration.

The cure time and heat setting during production directly impact your shirt’s longevity. A professionally printed screen printed t-shirt that has been fully cured should last for 5-8 years with appropriate care, potentially enduring 100 washes or more before showing signs of fading.

Why Screen Printed Shirts Need Special Care

While screen printed designs are remarkably durable when properly produced, they require specific care to maintain their quality. The ink layer that creates those bold, vibrant graphics can be compromised by excessive heat, harsh chemicals, and mechanical stress from washing and drying.

The print durability depends on several interconnected factors:

- Ink quality and type: High-quality plastisol inks are specifically formulated for garment printing

- Proper curing: Incomplete curing makes prints susceptible to washing damage

- Fabric composition: Cotton and cotton blends hold screen prints better than synthetic materials

- Care practices: Your washing and drying methods significantly impact print longevity

Understanding these factors helps you make informed decisions about garment care instructions. Even a perfectly printed shirt can deteriorate quickly if exposed to hot water washes, chlorine bleach, or high-heat drying cycles repeatedly.

Pre-Washing Essentials: Setting Up for Success

Allow Adequate Cure Time

If you’ve just purchased or received a freshly printed shirt, patience is crucial. Custom printed tees require at least 24 hours to fully cure after printing. During this period, the ink undergoes final bonding with the fabric. Washing too soon can compromise the print’s adhesion and durability.

Read the Care Label

Every screen printed garment comes with specific care instructions based on its fabric type and printing method. These labels provide vital information about wash temperature recommendations, whether the item can withstand machine washing, and any special considerations. Some garment-dyed shirts, for instance, require separate washing before wearing to prevent dye bleeding.

Sort Your Laundry Strategically

Proper sorting is fundamental to preserve screen print quality. Group your printed tees with similar items:

- By color: Separate darks from lights to prevent color transfer and maintain color preservation

- By weight and texture: Heavy materials like jeans can be abrasive to lighter printed tees during the wash cycle

- By fabric type: Cotton shirts wash differently than synthetic blends

This sorting strategy minimizes friction and mechanical stress that can damage prints over time.

The Best Way to Wash Screen Printed Shirts: Step-by-Step Methods

Hand Washing Method: The Gentlest Approach

Hand washing remains the gold standard for custom t-shirt care, offering the most gentle treatment for your screen printed clothing. Here’s how to do it effectively:

- Turn inside out: Always flip your shirts inside-out to protect the design from direct water pressure and friction

- Prepare the water: Fill a basin or sink with cool or cold water—ideally below 30°C (86°F)

- Add mild detergent: Use a small amount of gentle, bleach-free detergent. Avoid products with harsh additives

- Pre-treat stains: Apply a gentle stain remover to any affected areas before washing. Buff gently with a clean washcloth—never use abrasive brushes

- Soak and agitate: Submerge the shirt and let it soak for at least 10 minutes. Gently agitate the water with your hands to clean the fabric

- Rinse thoroughly: Use cool running water until all soap residue is removed

- Remove excess water: Gently squeeze—never wring or twist—the fabric to remove water

Hand washing provides complete control over how much mechanical stress your printed designs endure, making it ideal for particularly valuable or delicate custom printed clothing.

Machine Washing Screen Printed Shirts: Doing It Right

When time constraints make hand washing impractical, machine washing can still protect your prints if done correctly. Follow these guidelines from professional printing experts:

Before Loading:

- Turn shirts inside-out without exception

- Pre-treat any stains with appropriate removers

- Ensure similar colors and weights are grouped together

- Don’t overfill the washing machine—crowding increases friction

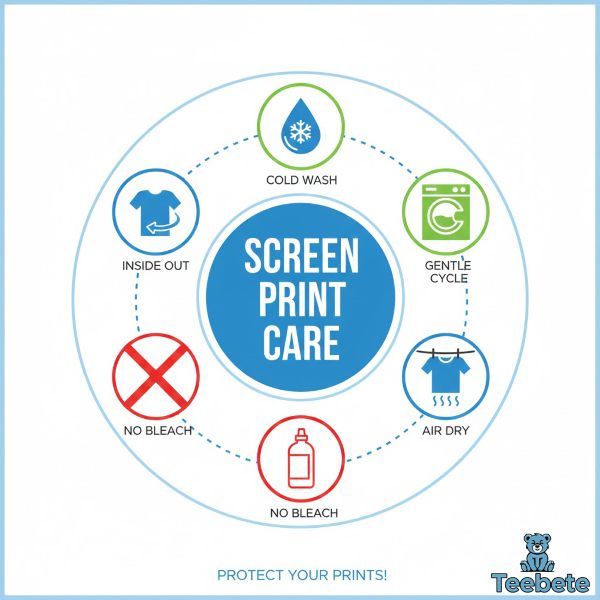

Washing Settings:

- Water temperature: Use cold water exclusively. Wash temperature should never exceed 30°C (86°F) as hot water softens plastisol ink and accelerates fading

- Cycle selection: Choose the gentle or delicate cycle to minimize agitation

- Detergent choice: Use mild detergent specifically designed for colors. Avoid formulas containing bleach, optical brighteners, or excessive enzymes

- Avoid harmful additives: Never use fabric softener, which can leave residue on prints and affect their appearance and breathability

What to Avoid When Washing Screen Printed Clothing

Certain practices virtually guarantee damage to your graphic tees:

Never Use Bleach: Both chlorine bleach and oxygen-based bleach products can cause prints to fade dramatically and weaken the bond between ink and fabric. According to industry care guidelines, bleach is one of the most destructive substances for screen printed garments.

Skip Fabric Softener: These products coat fabric fibers with chemicals that can interfere with ink adhesion and create an undesirable residue on prints. They also reduce the breathability of your printed tees.

Avoid Hot Water: Heat causes plastisol ink to soften slightly, making it more susceptible to color erosion and mechanical damage during the wash cycle.

Don’t Overload the Washer: Overcrowding creates excessive friction between garments, which can cause prints to rub against other items and wear down prematurely.

Drying Screen Printed T-Shirts: Preserving Print Integrity

How you dry your screen printed shirts matters as much as how you wash them. Heat is the primary enemy of print longevity during the drying process.

Air Drying: The Optimal Method

Air drying is universally recommended by screen printing professionals as the safest drying method. Here’s how to do it properly:

Hanging Method:

- Hang shirts on a sturdy hanger in a well-ventilated area

- Keep them away from direct sunlight, which can cause colors to fade over time

- Ensure the shirt hangs smoothly to minimize wrinkles

Flat Drying Method:

- Lay the shirt flat on a clean, dry towel

- Reshape the garment gently while wet to prevent distortion

- Place in a shaded area with good air circulation

- This method is particularly effective for preventing stretching of necklines and hems

Air drying completely eliminates heat exposure, which prevents fiber puffing and the resulting fibrillation—a process where fabric fibers poke through the ink layer, making prints appear faded or worn.

Machine Drying: When You Must Use a Dryer

If circumstances require machine drying, take these precautions:

- Use the lowest heat setting: Tumble dry low is essential to minimize heat damage

- Keep shirts inside-out: This protection layer matters even more during drying

- Remove promptly: Take shirts out as soon as the cycle ends or, ideally, while they’re still slightly damp

- Finish air drying: Complete the drying process by laying shirts flat or hanging them

Research indicates that excessive heat from dryers can cause ink to crack and peel while also causing fabric shrinkage. The combination of heat and mechanical tumbling creates the worst possible conditions for printed designs.

Never Take Plastisol Prints to Dry Cleaners

Professional dry cleaning uses harsh chemical solvents that make plastisol ink brittle, causing it to crack and peel. Screen printing experts strongly advise against dry cleaning for any garments with plastisol-based prints. If you absolutely must use professional cleaning services, confirm the shirt uses water-based inks rather than plastisol.

Ironing and Storage: Completing the Care Cycle

Ironing Screen Printed Shirts Safely

Minimize ironing whenever possible—wrinkle-free drying techniques eliminate the need in most cases. When ironing becomes necessary:

- Turn inside-out: Never iron directly on the printed design

- Use low heat: Set your iron to the lowest effective temperature

- Use a barrier cloth: Place a thin towel or pressing cloth over the area

- Avoid the print area: Iron around designs rather than over them

Direct heat contact can cause plastisol inks to melt, distort, or separate from the fabric, permanently damaging your custom design.

Proper Storage for Screen Printed Clothing

How you store your printed tees between wears also affects their longevity:

Folding Method:

- Fold neatly along natural creases

- Store in a cool, dry environment

- Keep away from direct sunlight or heat sources

- Avoid compressing heavily under other garments

Hanging Method:

- Use sturdy hangers that support the shoulders properly

- Maintain adequate spacing between garments

- Store in a dark or low-light closet to prevent fading

Proper storage prevents unnecessary wear on both the fabric and the printed design, ensuring your shirts look fresh whenever you’re ready to wear them.

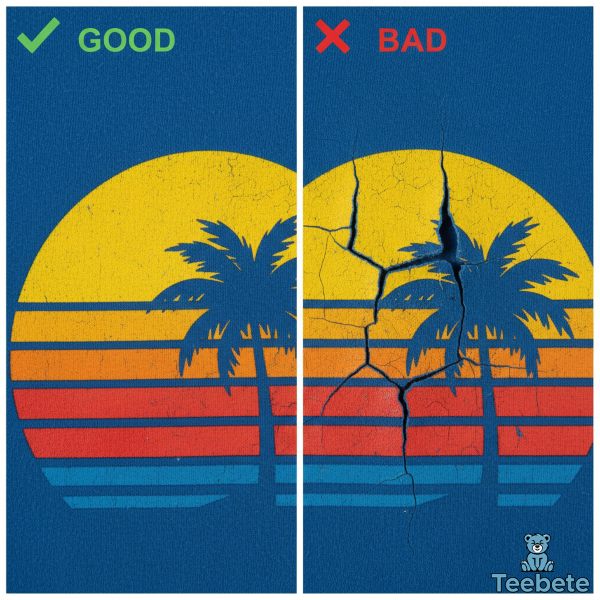

How to Prevent Screen Print from Cracking and Peeling

Cracking and peeling are the most common complaints about screen printed garments, but they’re largely preventable with proper care:

Ensure Professional Printing Quality

The foundation of print durability begins before you even own the shirt. Working with experienced printers who use high-quality plastisol inks and proper curing techniques is essential. Well-cured prints that have received adequate heat setting during production resist cracking far better than improperly cured alternatives.

Minimize Heat Exposure

Since plastisol ink can crack when exposed to high heat repeatedly, keep wash temperatures cold and dryer settings low. Each high-heat exposure weakens the ink’s flexibility slightly, and cumulative exposure leads to visible cracking.

Add Stretch Additives (For Printers)

If you’re having shirts custom printed, request that the printer use stretch additives in the ink formulation. These additives improve ink flexibility, making prints more resistant to cracking on garments that undergo stretching during wear—particularly important for athletic wear or fitted shirts.

Handle Gently

Rough treatment—aggressive wringing, twisting, or pulling—puts mechanical stress on the print. This stress can create micro-cracks that develop into visible damage over time. Always handle your printed shirts gently during washing and drying.

Understanding Different Ink Types and Their Care Requirements

While plastisol ink dominates the screen printing industry, other ink types exist, each with specific care needs:

Plastisol Ink Care

Plastisol remains the most popular choice due to its durability, opacity, and ease of use. These inks:

- Sit on top of fabric rather than soaking in

- Create slightly raised, opaque designs

- Are highly resistant to fading when properly cared for

- Can crack if repeatedly exposed to excessive heat

- Should never be dry cleaned

Water-Based Ink Care

Water-based inks penetrate fabric fibers, creating softer, more breathable prints. They:

- Require similar cold-water washing

- May fade faster with frequent washing than plastisol

- Are more environmentally friendly

- Work best on lighter-colored cotton fabrics

- Can be dry cleaned (unlike plastisol)

Specialty Ink Considerations

Specialty effects like puff ink, metallic, glitter, or glow-in-the-dark require extra care:

- Puff prints: Extra gentle handling to prevent crushing the raised texture

- Metallic inks: Avoid excessive heat that can dull the metallic finish

- Glitter prints: May shed slightly despite proper care

- Foil prints: Particularly susceptible to cracking; air dry only

Troubleshooting Common Screen Print Care Issues

My Print is Already Fading—What Can I Do?

Once fading has begun, you cannot reverse it, but you can slow further deterioration:

- Switch immediately to cold water washing

- Always turn garments inside-out

- Air dry exclusively from this point forward

- Minimize washing frequency by spot-cleaning minor issues

The Print Feels Stiff or Rough

This typically indicates:

- Inadequate rinsing (detergent residue)

- Use of fabric softener (stop immediately)

- Excessive heat during drying (reduce temperature)

Rewashing in cold water with thorough rinsing may help soften the print.

Colors are Bleeding or Transferring

This usually occurs with:

- Garment-dyed shirts that weren’t pre-washed

- Washing dissimilar colors together

- Water temperature too hot

Solution: Always wash new garment-dyed items separately in cold water before wearing, and maintain strict color separation.

White Ink is Turning Colors

This phenomenon, called dye migration, occurs when fabric dyes transfer into screen printing ink. It’s most common with:

- 100% polyester garments

- Red, purple, or charcoal colored fabrics

- Shirts exposed to excessive heat

Prevention requires professional printers to use low-bleed inks and proper techniques. As a consumer, minimize heat exposure to reduce this risk.

How to Make Screen Printed Shirts Last Longer: Expert Tips

Extending the life of your screen printed clothing involves combining all these care practices with a few additional strategies:

Reduce Washing Frequency

Not every wear requires a wash. Spot-clean minor stains and air out shirts between wears when possible. Each wash cycle, even when done properly, causes minimal wear—reducing frequency extends overall lifespan proportionally.

Invest in Quality from the Start

Professional printing companies that use premium inks and proper curing procedures create more durable prints. While quality shirts may cost more initially, their longevity provides better value.

Rotate Your Collection

Wearing the same shirt repeatedly accelerates wear. Rotate through your collection to distribute washing cycles across multiple garments, extending each shirt’s lifespan.

Address Stains Immediately

Prompt stain treatment with gentle, shirt-safe products prevents the need for aggressive washing or repeated cycles. The sooner you treat a stain, the easier it removes with gentle methods.

Consider Hand Washing Favorites

For your most treasured or valuable screen printed shirts, commit to hand washing exclusively. The time investment pays dividends in extended garment life.

Environmental Considerations in Screen Print Care

Proper care for your screen printed shirts can also align with environmental consciousness:

Cold Water Benefits:

- Reduces energy consumption significantly

- Effectively cleans modern fabrics

- Extends garment life, reducing textile waste

- Causes less color fading across all garments

Mild Detergent Choices:

- Look for biodegradable formulations

- Avoid products with phosphates or excessive chemicals

- Use recommended amounts—more isn’t better

- Consider eco-friendly brands designed for cold water

Air Drying Advantages:

- Eliminates dryer energy consumption entirely

- Reduces carbon footprint

- Gentler on all clothing types

- Extends the life of both prints and fabrics

By combining proper screen print care with environmental awareness, you maintain your favorite shirts while minimizing ecological impact.

Frequently Asked Questions About Screen Printed T-Shirt Care

Absolutely. Modern screen printing techniques create designs durable enough for machine washing when you follow proper guidelines: cold water, gentle cycle, mild detergent, and inside-out positioning. Avoid harsh chemicals and excessive heat.

Cold water—ideally 30°C (86°F) or below—is optimal. This temperature effectively cleans while preventing ink softening and color fading. Never use hot water on screen printed garments.

With professional printing and proper care, screen printed shirts can last 5-8 years and withstand 100 or more washes before showing significant fading. Quality printing and careful maintenance are both essential for maximum longevity.

While special detergent isn’t mandatory, mild formulations without bleach, harsh enzymes, or optical brighteners work best. Color-safe detergents designed for delicate fabrics are ideal choices.

Properly cured plastisol or water-based inks designed for garment printing will not wash away. If a print washes away or deteriorates dramatically, it indicates inadequate curing during production or extremely harsh washing conditions.

Well-cured prints feel smooth, show no tackiness, and don’t transfer ink when rubbed. If you notice ink transfer onto other garments or your skin, the shirt may not have been fully cured. Contact the printer for a replacement.

Conclusion: Preserving Your Screen Printed Investments

Screen printed t-shirts represent personal expression, memories, and often significant financial investment. Whether you’re caring for custom designs from Teebete or other quality printers, following this comprehensive screen print care guide ensures your printed tees maintain their vibrant colors and crisp designs for years.

The key principles bear repeating:

- Always turn inside out before washing and drying

- Use cold water exclusively to prevent ink softening and color fading

- Choose mild detergent without bleach or fabric softener

- Opt for air drying whenever possible

- Handle gently throughout the care process

- Store properly in cool, dark environments

By understanding the science behind screen printing, recognizing the vulnerabilities of plastisol ink, and implementing proper washing, drying, and storage techniques, you can dramatically extend the life of your favorite screen printed shirts. These practices transform your custom tees from temporary fashion items into lasting wardrobe staples that continue delivering joy, memories, and style wash after wash.

Remember that proper care begins with quality printing—always work with reputable printers who use high-quality inks and proper curing techniques. Combined with the maintenance practices outlined in this guide, your screen printed clothing will serve you well for years to come, maintaining the vibrant, eye-catching designs that made you love them in the first place.

Quick Reference Summary Table

| Care Aspect | Best Practice | What to Avoid |

|---|---|---|

| Washing Method | Hand wash or gentle machine cycle | Aggressive cycles or overfilling washer |

| Water Temperature | Cold water (30°C/86°F or below) | Hot or warm water |

| Detergent | Mild, color-safe detergent | Bleach, fabric softener, harsh chemicals |

| Pre-Treatment | Turn inside-out; pre-treat stains gently | Aggressive scrubbing with brushes |

| Drying Method | Air dry flat or hanging in shade | High heat tumble drying |

| Drying Alternative | Tumble dry low, remove while damp | Extended high-heat drying cycles |

| Ironing | Inside-out, low heat, with barrier cloth | Direct ironing on print area |

| Storage | Cool, dry, dark place; folded or hung properly | Direct sunlight, compressed storage |

| Washing Frequency | Minimize; spot clean when possible | Washing after every wear |

| Color Sorting | Separate darks, lights, and similar textures | Mixing all colors and fabric weights |

| Special Considerations | Allow 24-hour cure time for new shirts | Washing immediately after purchase |

| Professional Cleaning | Avoid for plastisol prints entirely | Taking plastisol-printed shirts to dry cleaners |

This reference table provides quick guidance for maintaining your screen printed t-shirts. For detailed explanations of each practice and the science behind proper care, refer to the comprehensive sections above. Following these guidelines consistently will maximize the longevity, appearance, and value of your custom printed clothing collection.

Hi, I’m Mia Wilson. I’m a journalist and content creator based in New York with over six years of experience covering sports, holidays, fan culture, and community events across the United States. I focus on exploring team histories, traditions, celebrations, and the broader impact of sports and cultural events on local communities. I’m passionate about providing accurate, engaging, and educational content for readers of all ages, helping them understand the stories, experiences, and events that make sports and celebrations so meaningful.